Method and device for regenerating vanadium and tungsten denitration catalyst

A denitrification catalyst and regeneration device technology, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve the problems of reduction, loss of active components, specific surface area, etc., to reduce regeneration costs, save applicable amount, Effect of low regenerative energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

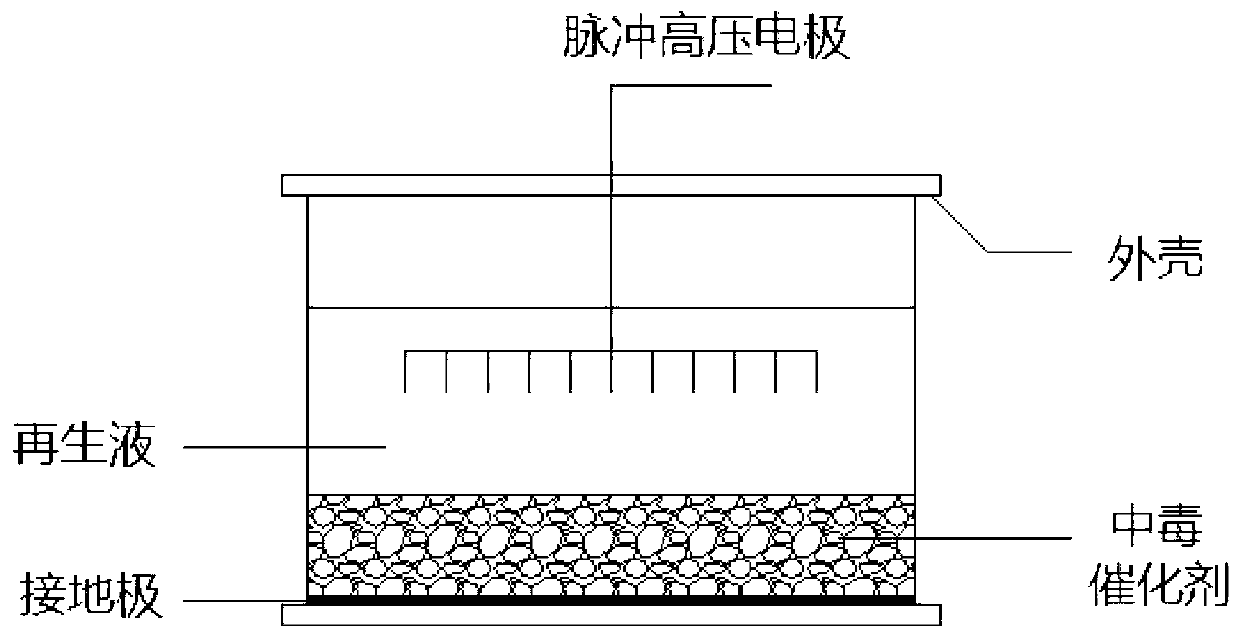

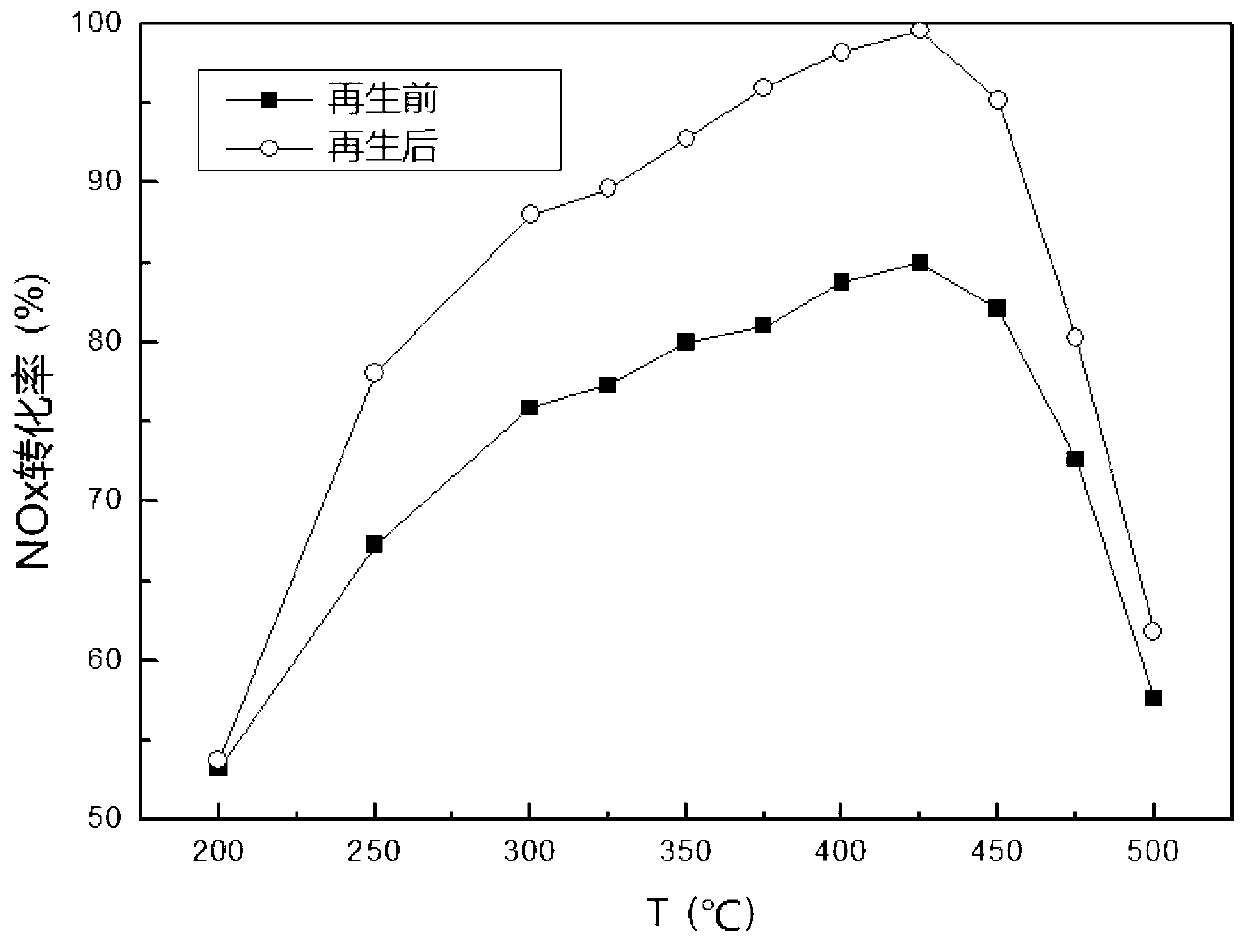

Embodiment 1

[0032] The sample is collected from a poisoned 60×60×50mm honeycomb V 2 o 5 -WO 3 (MoO 3 ) / TiO 2 Catalyst, use deionized water to wash away the floating ash on the surface of the catalyst and in the pores. Then put the washed catalyst into a low-temperature plasma regeneration reactor, add 3L regeneration liquid, and the regeneration liquid immerses the catalyst and the discharge electrode. The regeneration solution contains 4wt% ammonium metatungstate, 1wt% ammonium metavanadate, 0.5wt% ammonium molybdate, and acetic acid. Close the regenerative reactor, switch on the high-voltage pulse power supply, and discharge for 90 minutes with a discharge voltage of 25kV. After the discharge was completed, the catalyst was taken out, and dried in a drying oven at 110° C. for 3 hours. Regeneration ends.

[0033] Catalytic activity evaluation and performance test before and after catalyst regeneration: The regenerated catalyst was pulverized, ground, tabletted, and sieved, and the...

Embodiment 2

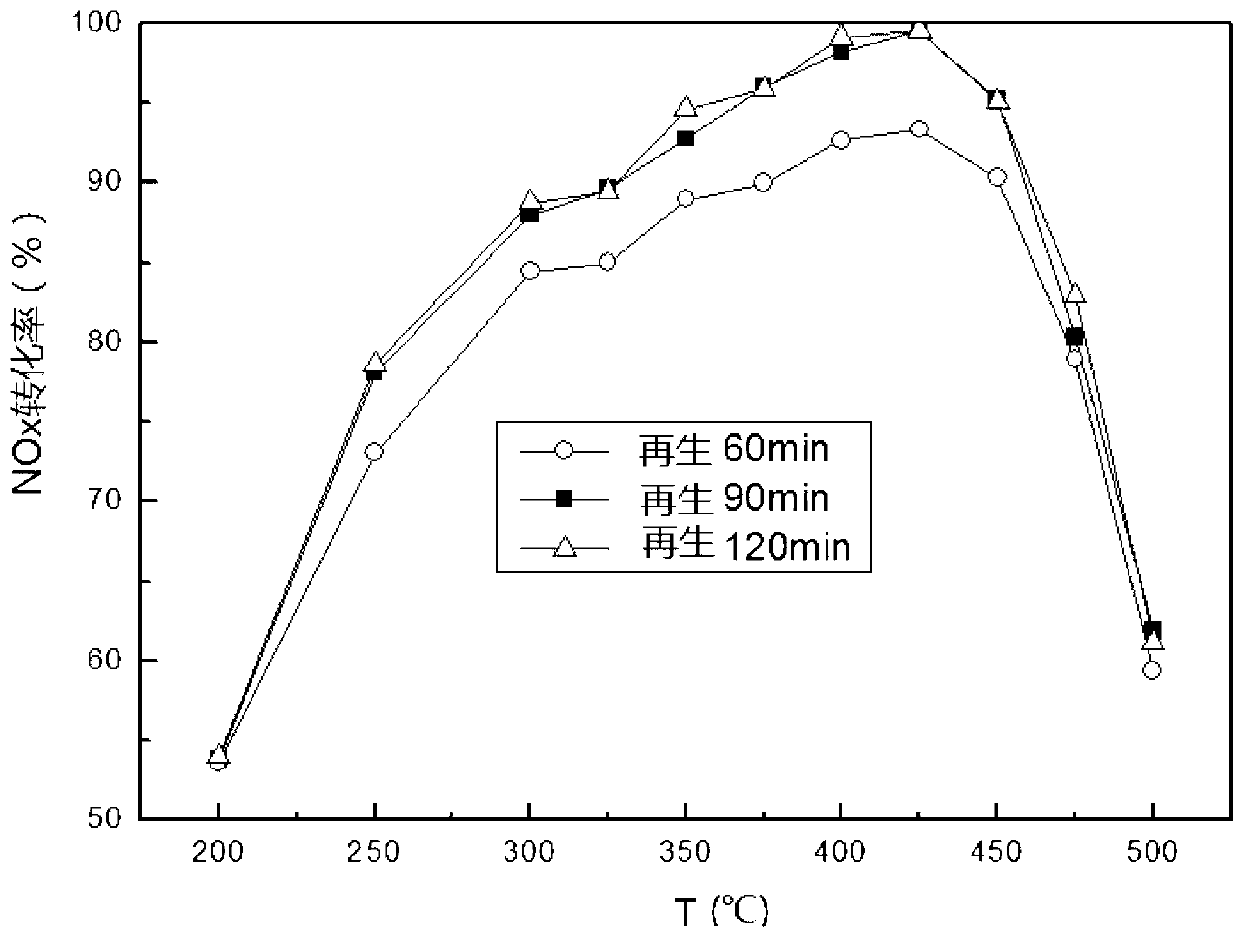

[0036] The samples were collected from several poisoned 60×60×50mm honeycomb V 2 o 5 -WO 3 (MoO 3 ) / TiO 2Catalyst, use deionized water to wash away the floating ash on the surface of the catalyst and in the pores. Then put the washed piece of catalyst into the low-temperature plasma regeneration reactor, add 3L regeneration liquid, and the regeneration liquid immerses the catalyst and the discharge electrode. The regeneration solution contains 4wt% ammonium metatungstate, 1wt% ammonium metavanadate, 0.5wt% ammonium molybdate, and acetic acid. The three poisoned catalysts were respectively discharged in the liquid-phase plasma regeneration reactor for 60min, 90min, and 120min at a discharge voltage of 25kV. After the discharge was completed, the catalyst was taken out, and dried in a drying oven at 110° C. for 3 hours. Regeneration ends.

[0037] Catalytic activity evaluation and performance test before and after catalyst regeneration: The regenerated catalyst was pulver...

Embodiment 3

[0040] The samples were collected from several poisoned 60×60×50mm honeycomb V 2 o 5 -WO 3 (MoO 3 ) / TiO 2 Catalyst, use deionized water to wash away the floating ash on the surface of the catalyst and in the pores. Then put the washed piece of catalyst into the low-temperature plasma regeneration reactor, and add 3L of three kinds of regeneration solutions respectively, and the regeneration solution immerses the catalyst and the discharge electrode.

[0041] The components of the three regeneration fluids are:

[0042] (1) 4wt% ammonium metatungstate, 1wt% ammonium metavanadate, acetic acid;

[0043] (2) Ammonium metatungstate 4wt%, ammonium metavanadate 1wt%, ammonium molybdate 0.5wt%, acetic acid;

[0044] (3) Ammonium paratungstate 4wt%, ammonium paravanadate 1wt%, ammonium molybdate 0.5wt%, acetic acid;

[0045] The poisoned catalysts were sequentially discharged and regenerated for 90 minutes in plasma regeneration reactors equipped with regeneration solutions of d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com