Preparation method of catalyst applied to tert-butylamine production through direct amination of isobutene and application

A catalyst and isobutylene technology, applied in the direction of physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of affecting reactants and products, blocking orifices, easy to fall on the outer surface, etc., to achieve high reactivity , low reaction pressure and temperature, high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

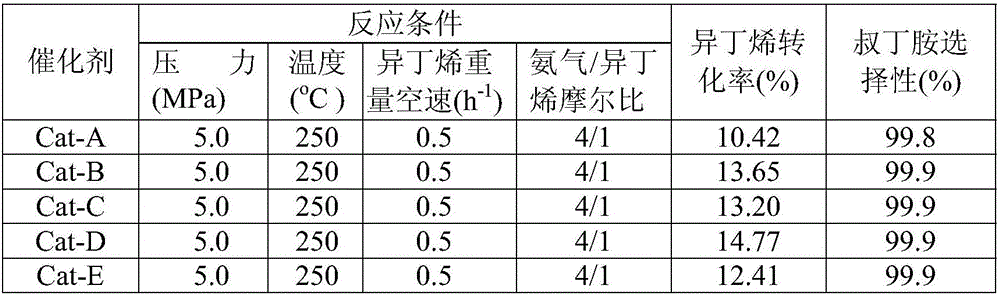

Embodiment 1

[0020] Take by weighing 0.243 gram of ammonium fluoride, the HZSM-11 molecular sieve of 10 grams, add 6.25 grams of 40% (weight) silica sol (Na 2 (0:0.04% by weight) mixed, extruded, and dried at 120°C to obtain sample B. A mixture of 5 grams of tetrabutylammonium hydroxide and 30 grams of distilled water was added to the reaction kettle in advance, and the sample B was placed in the reaction kettle above the porous stainless steel mesh and sealed and then subjected to gas-solid phase treatment at 180° C. for 14 hours.

[0021] After the product was taken out, it was washed twice with water, dried at 120°C, and calcined at 400°C for 3 hours to obtain the catalyst as Cat-B. Defined as 100% with the XRD spectrogram feature diffraction peak intensity sum of Cat-A in Comparative Example 1, other samples (such as Cat-B, Cat-C, Cat-D, Cat-E) and its ratio obtain relative crystallinity Spend. Cat-B has a relative crystallinity of 105%.

Embodiment 2

[0023] Take by weighing 0.545 gram of ammonium fluoride, the HZSM-11 molecular sieve of 10 grams, add 12 grams of 40% (weight) silica sol (Na 2 (0:0.03% by weight) mixed, extruded, and dried at 120°C to obtain sample B; a mixture of 10 grams of tetrabutylammonium hydroxide and 20 grams of distilled water was added in advance in the reactor, and sample B was placed in the reactor to be porous Gas-solid phase treatment was carried out at 180° C. for 24 hours after sealing above the stainless steel mesh. After the product was taken out, it was washed twice with water, dried at 120°C, and calcined at 450°C for 4 hours, and the catalyst obtained was designated as Cat-C. XRD results show that the relative crystallinity of Cat-C is 120%.

Embodiment 3

[0025] Take by weighing 0.070 gram of ammonium fluoride, the HZSM-11 molecular sieve of 10 grams, add 8 grams of beer silica gel (Na 2 (0:0.02% by weight) mixed, extruded, and dried at 120°C to obtain sample C. A mixture of 4 grams of tetrabutylammonium hydroxide and 15 grams of distilled water was added to the reaction kettle in advance, and the sample C was placed in the reaction kettle above the porous stainless steel mesh and sealed and then subjected to gas-solid phase treatment at 120° C. for 90 hours. After the product was taken out, it was washed twice with water, dried at 140°C, and calcined at 350°C for 6 hours. The catalyst obtained was designated as Cat-D. XRD results showed that the relative crystallinity of Cat-D was 145%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com