Nano ultraviolet screener and method for preparing high-performance uvioresistant fabric

A UV shielding agent, high-performance technology, applied in plant fibers, textiles, papermaking, fiber treatment, etc., can solve the problems of reduced anti-ultraviolet performance, weak combination of anti-ultraviolet materials and fabrics, hand feeling, poor whiteness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

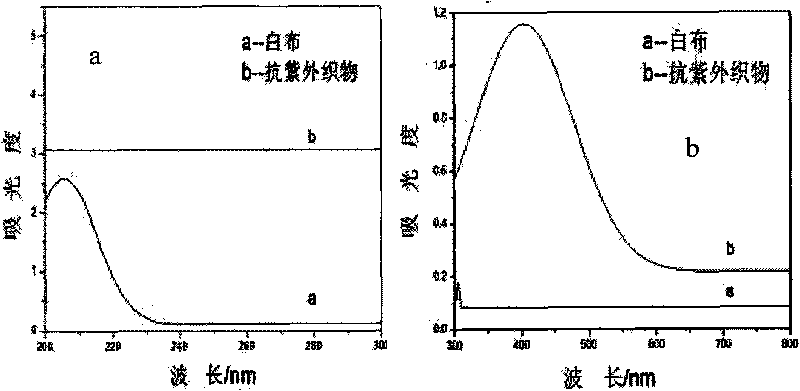

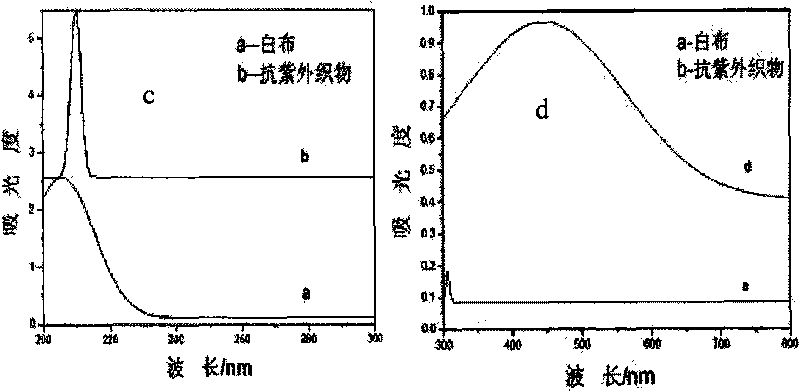

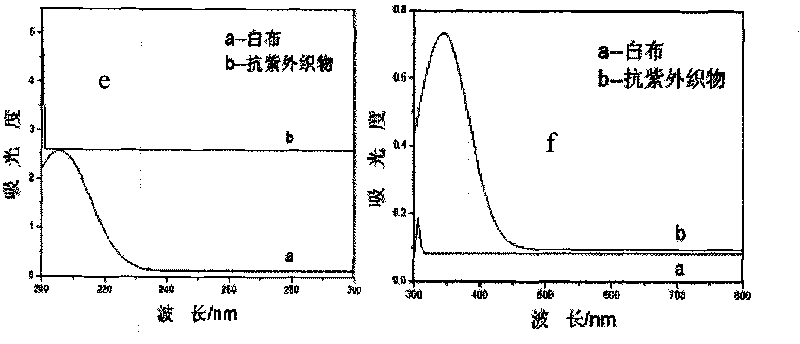

Image

Examples

Embodiment 1

[0033] 1) Ce(NO 3 )·6H 2 O was dissolved in deionized water to form a concentration of 16.7 × 10 -3 mol / L transparent solution;

[0034] 2) Ce(NO 3 )·6H 2 Add O solution, toluene, oleic acid and tert-butylamine into the polytetrafluoroethylene liner at one time, put the pressure bomb into the electric furnace, and heat at 180°C for 24 hours. After the reaction, take the upper oil layer, add ethanol, centrifuge, and dry the obtained solid at 70°C for 24 hours to obtain the above-mentioned nano-ultraviolet shielding machine

[0035] In the above preparation method, Ce(NO 3 )·6H 2 The volume ratio of O, toluene, oleic acid and tert-butylamine is: 100:70:6:1.

[0036] In the above preparation method, the step of centrifugal separation is: centrifugal separation at 8000 R / min for 10 minutes, and the number of centrifugal separations is more than 3 times.

[0037] The development method of using the above-mentioned nano-ultraviolet shielding agent to prepare high-performance...

Embodiment 2

[0041] 1) Ce(NO 3 )·6H 2 O is dissolved in deionized water to form a transparent solution with a concentration of 0.05mol / L;

[0042] 2) Ce(NO 3 )·6H 2 Add O solution, toluene, oleic acid and tert-butylamine into the polytetrafluoroethylene liner at one time, put the pressure bomb into the electric furnace, and heat at 200°C for 48 hours. After the reaction, take the upper oil layer, add ethanol, centrifuge, and dry the obtained solid at 80°C for 12 hours to obtain the above-mentioned nano-ultraviolet shielding machine

[0043] In the above preparation method, Ce(NO 3 )·6H 2 The volume ratio of O, toluene, oleic acid and tert-butylamine is: 100:80:9:2.

[0044] In the above preparation method, the step of centrifugal separation is: centrifugal separation at 10,000 R / min for 10 minutes, and the number of centrifugal separations is more than 3 times.

[0045] The method for preparing high-performance anti-ultraviolet fabrics using the above-mentioned nano-ultraviolet shield...

Embodiment 3

[0048] 1) Ce(NO 3 )·6H 2 O is dissolved in deionized water to form a transparent solution with a concentration of 0.09mol / L;

[0049] 2) Ce(NO 3 )·6H 2 Add O solution, toluene, oleic acid and tert-butylamine into the polytetrafluoroethylene liner at one time, put the pressure bomb into the electric furnace, and heat at 180°C for 36 hours. After the reaction, take the upper oil layer, add ethanol, centrifuge, and dry the obtained solid at 70°C for 16 hours to obtain the above-mentioned nano-ultraviolet shielding machine

[0050] In the above preparation method, Ce(NO 3 )·6H 2 The volume ratio of O, toluene, oleic acid and tert-butylamine is: 100:90:11:3.

[0051] In the above preparation method, the step of centrifugal separation is: centrifugal separation at 9000 R / min for 15 minutes, and the number of centrifugal separations is more than 3 times.

[0052] The method for preparing high-performance anti-ultraviolet fabrics using the above-mentioned nano-ultraviolet shiel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com