Method for preparing carbon fibers from acrylic fibers

A technology of carbon fiber and acrylic fiber, which is applied in the field of carbon fiber preparation, can solve the problems of high corrosiveness of mixed acid equipment, inapplicability to actual production, and influence on the performance of carbon fiber, so as to reduce the initial temperature of thermal stabilization reaction, suitable for large-scale production, The effect of short modification time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) adopt dry jet wet spinning or wet spinning technology to prepare acrylic fiber;

[0034] (2) configuration mass percentage concentration is the guanidine hydrochloride aqueous solution of 0.5%;

[0035] (3) Immerse a bundle of acrylic fibers prepared in step (1) into the guanidine hydrochloride aqueous solution, and keep it in a constant temperature water bath at 60° C. for 10 minutes, then take out the acrylic fibers and dry them at 60° C.

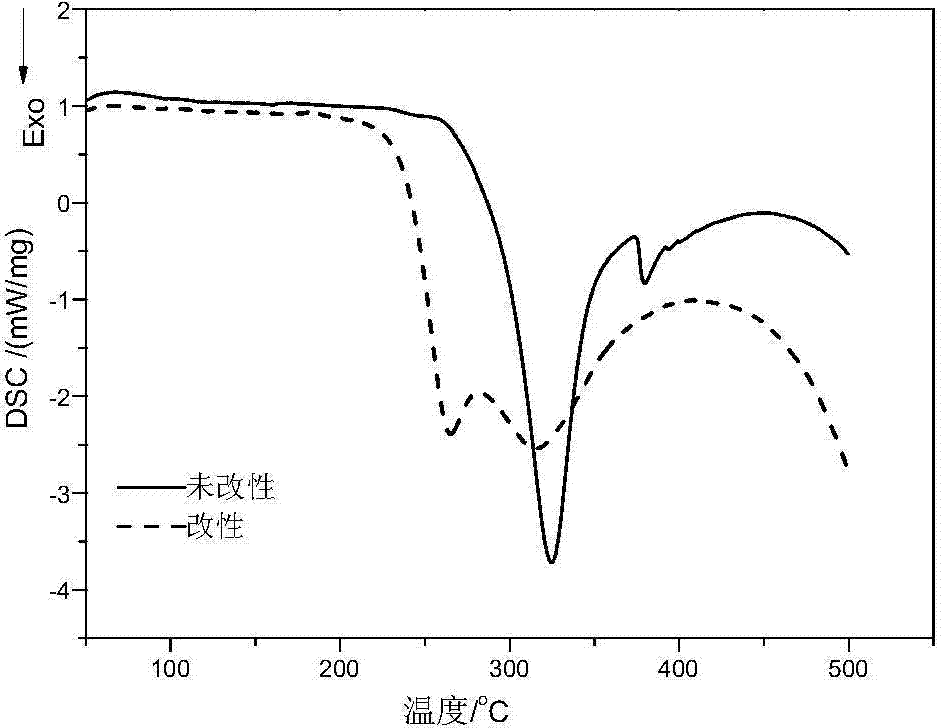

[0036] Adopt thermal analyzer (DSC) to carry out thermal performance analysis to the acrylic fiber that step (1) makes and the acrylic fiber after step (3) process, the result is as follows figure 1 shown, from figure 1 It can be seen from the figure that the thermal stabilization reaction initiation temperature of the acrylic fibers not modified by guanidine hydrochloride is 260°C, while the thermal stabilization reaction initiation temperature of the acrylic fibers modified by guanidine hydrochloride is greatly reduced, only...

Embodiment 2

[0041] (1) exactly the same as step (1) in embodiment 1, makes acrylic fiber;

[0042] (2) configuration mass percentage concentration is the ammonium acetate aqueous solution of 0.5%;

[0043] (3) Immerse a bundle of acrylic fiber in the ammonium acetate aqueous solution and keep it in a constant temperature water bath at 60°C for 10 minutes, then take out the acrylic fiber and dry it at 60°C.

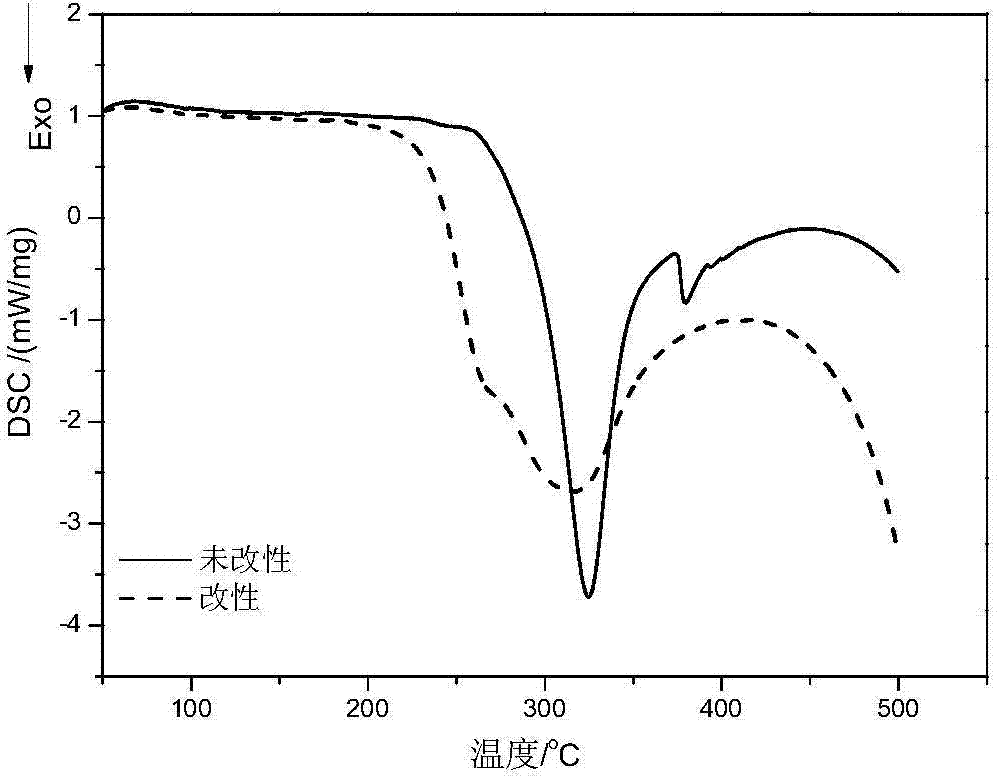

[0044] Adopt thermal analyzer (DSC) to carry out thermal performance analysis to the acrylic fiber that step (1) makes and the acrylic fiber after step (3) process, the result is as follows image 3 shown, from image 3 It can be seen from the figure that the initial temperature of the thermal stabilization reaction of the acrylic fiber without ammonium acetate modification is 260°C, while the thermal stabilization reaction initiation temperature of the acrylic fiber modified with ammonium acetate is greatly reduced, only 200°C. up to 23%.

[0045] The non-ammonium acetate-modified...

Embodiment 3

[0050] (1) exactly the same as step (1) in embodiment 1, makes acrylic fiber;

[0051] (2) configuration mass percentage concentration is the ammonium formate aqueous solution of 1%;

[0052] (3) Immerse a bundle of acrylic fiber in the ammonium formate aqueous solution, and keep it in a constant temperature water bath at 80°C for 10 minutes, then take out the acrylic fiber and dry it at 80°C.

[0053] Adopt thermal analyzer (DSC) to carry out thermal performance analysis to the acrylic fiber that step (1) makes and the acrylic fiber after step (3) process, the result is as follows Figure 4 shown, from Figure 4 It can be seen from the figure that the thermal stabilization reaction initiation temperature of acrylic fiber without ammonium formate modification is 260°C, while the thermal stabilization reaction initiation temperature of acrylic fiber modified with ammonium formate is greatly reduced, only 200°C, lower The range is 23%.

[0054] The non-ammonium formate-modifi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com