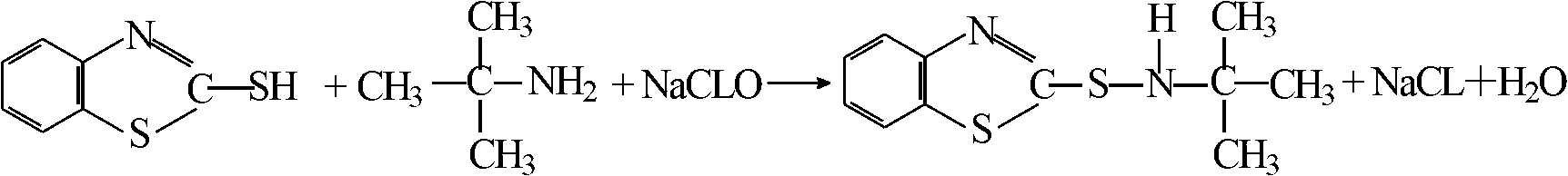

Synthesis method of rubber vulcanization accelerator TBBS (N-tert-butyl-2-benzothiazolesulfenamide)

A synthesis method and rubber vulcanization technology are applied in the synthesis field of crude MBT to produce TBBS, which can solve the problems of increased production cost, increased equipment investment, product pollution, etc., and achieves the effects of reducing three wastes, low cost and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

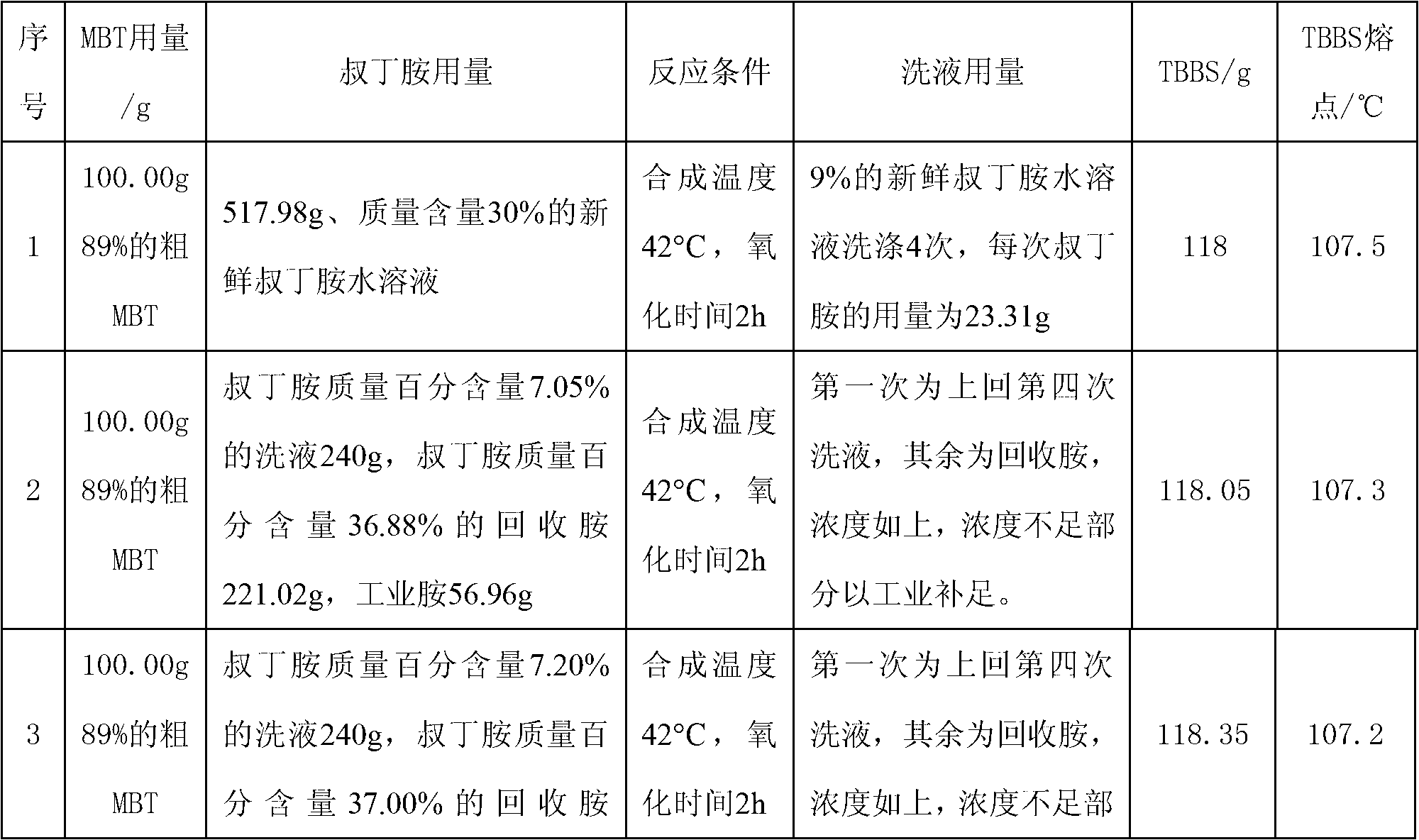

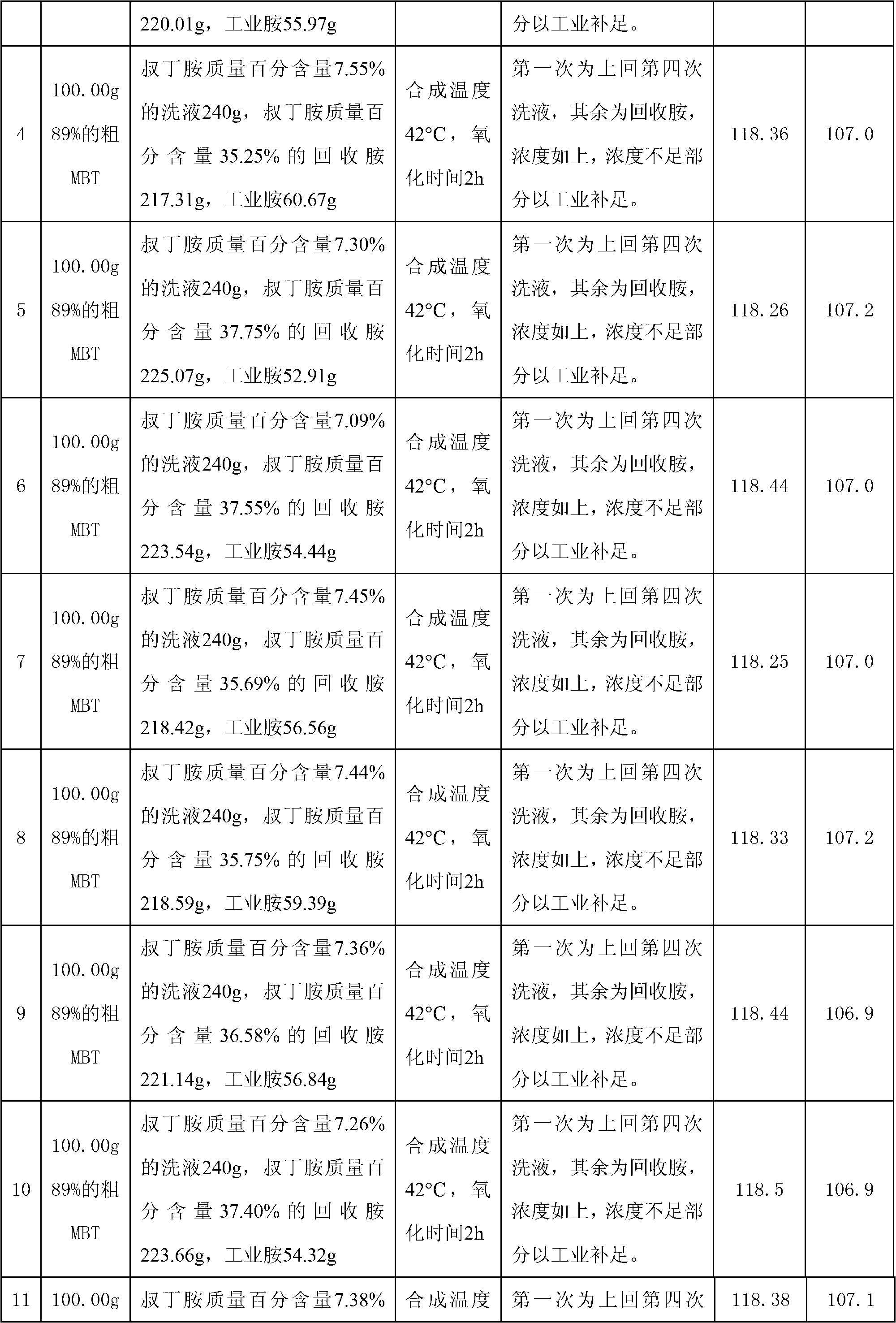

Examples

Embodiment 1

[0018] Add 100.00 g of crude MBT (measured to have a purity of 75%, mass percentage) into a reactor filled with 392.85 g of tert-butylamine aqueous solution with a mass content of 25% (the molar ratio of MBT to tert-butylamine after conversion is 1:3 ), and stir evenly; to the above reaction mixture, add a sodium hypochlorite solution with 13% available chlorine to oxidize and synthesize until the end of the reaction, the synthesis temperature is maintained at 30°C, and the oxidation time is 1.5h. The end of the oxidation is detected by copper acetate solution and starch potassium iodide solution ; The reaction mixture reacted to the end is suction filtered, and the filter cake is washed 5 times with 5% tert-butylamine aqueous solution by mass content, and the consumption of each tert-butylamine is 12.77g (65% of the amount of tert-butylamine added before the reaction). Then wash to neutrality with water, obtain qualified vulcanization accelerator TBBS 100.33g after filter cake...

Embodiment 2

[0020] Add 100.00g of crude MBT (measured to have a purity of 80%, mass percentage) into a reactor filled with 232.8g of tert-butylamine aqueous solution with a mass content of 45% (the molar ratio of MBT to tert-butylamine after conversion is 1:3 ), and stir evenly; to the above reaction mixture, add a sodium hypochlorite solution with 18% available chlorine to oxidize and synthesize until the end of the reaction, the synthesis temperature is maintained at 30°C, and the oxidation time is 1.5h. The end of the oxidation is detected by copper acetate solution and starch potassium iodide solution ; The reaction mixture reacted to the end is suction filtered, and the filter cake is washed 5 times with 5% tert-butylamine aqueous solution by mass content, and the consumption of each tert-butylamine is 12.77g (65% of the amount of tert-butylamine added before the reaction). Then wash to neutrality with water, obtain qualified vulcanization accelerator TBBS 100.02g after filter cake dr...

Embodiment 3

[0022] 100.00g of crude MBT (measured as 90% in purity, mass percentage) was added to a reactor filled with 436.50g of tert-butylamine (fresh) aqueous solution with a mass content of 45% (the molar ratio of MBT to tert-butylamine after conversion was 1:5), stir evenly; to the above reaction mixture, add sodium hypochlorite solution with 15.5% available chlorine to oxidize and synthesize until the end of the reaction, the synthesis temperature is maintained at 45°C, and the oxidation time is 2.5h. Potassium iodide solution detection; the reaction mixture that has reacted to the end is suction filtered, and the filter cake is washed twice with tert-butylamine (fresh) aqueous solution with a mass content of 45%, and the amount of tert-butylamine is 83.48g each time 85%), and then washed with water until neutral, and the filter cake was dried to obtain 118.61 g of qualified vulcanization accelerator TBBS.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com