Method for preparing dimethyl ether by liquid phase compression

A technology of dimethyl ether and liquid phase, which is applied in the field of pressurized production of dimethyl ether in liquid phase, which can solve the problems of high energy consumption, high reaction temperature, and high catalyst cost, so as to save power consumption, improve processing capacity, and reduce energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

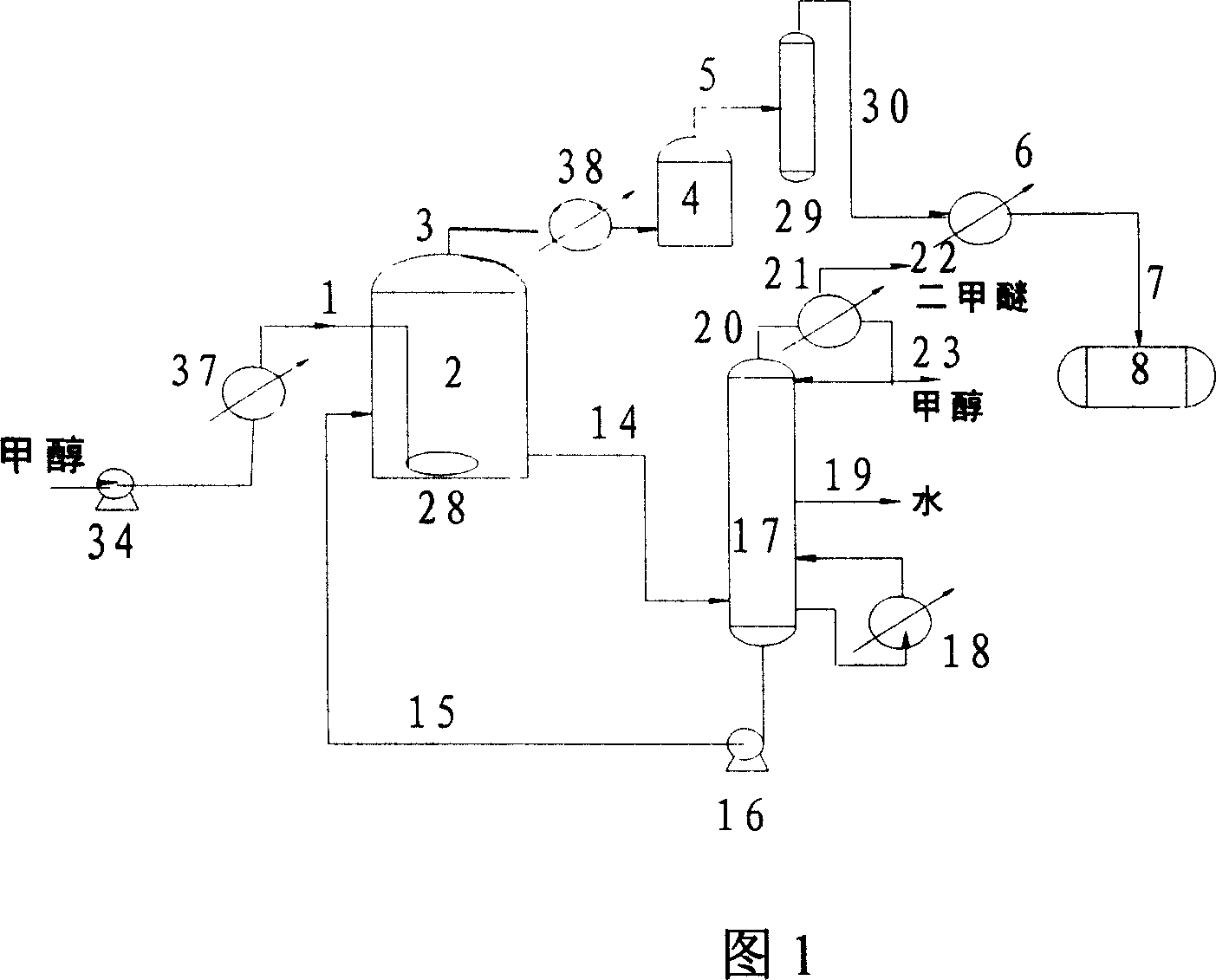

Embodiment 1

[0034] First put the concentrated sulfuric acid into the bubble column reactor, then heat the concentrated sulfuric acid to 120°C with 0.6Mpa steam, and then feed methanol with a content of 92% (wt) at a rate of 20t / h through the methanol feed pump. Continuously add to the bubble column reactor until the reaction temperature is controlled at 120°C and the reactor pressure rises to 0.3Mpa, open the top control valve of the bubble column reactor, and the gas phase passes through the heat exchanger, gas-liquid separator, and drying After the condenser and the condenser, a liquid dimethyl ether product with a content greater than 98.5% is obtained.

Embodiment 2

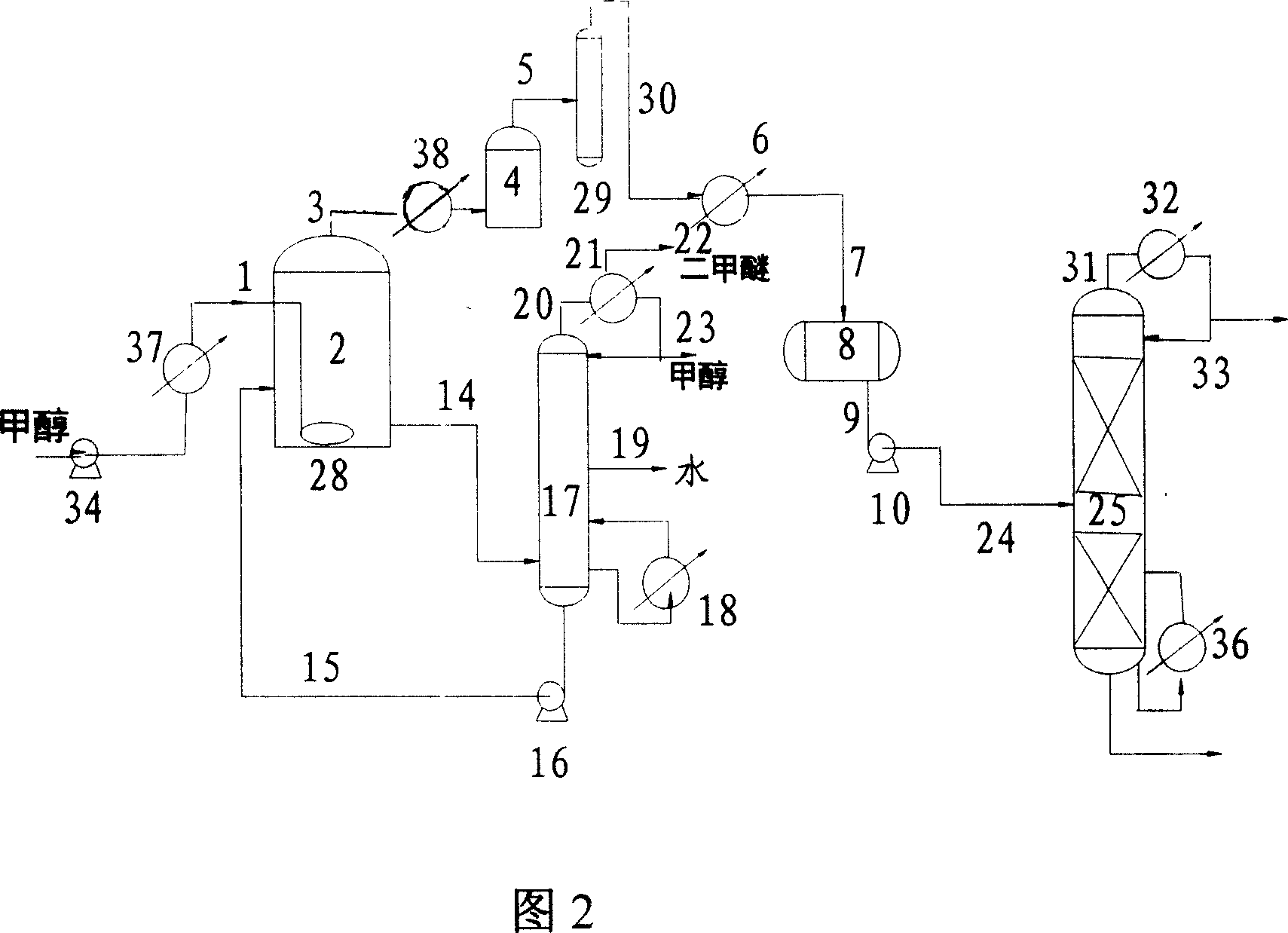

[0036] First put the concentrated sulfuric acid into the bubble column reactor, then heat the concentrated sulfuric acid to 130°C with 1.2Mpa steam, and then feed the methanol with a content of 99% (wt) at a speed of 15t / h through the methanol feed pump. Continuously add to the bubble column reactor until the reaction temperature reaches 380°C and the reactor pressure rises to 3.5Mpa, open the top control valve of the bubble column reactor, and the gas phase passes through the heat exchanger, gas-liquid separator, and dryer And after the condenser, a liquid dimethyl ether product with a content greater than 98.5% is obtained.

Embodiment 3

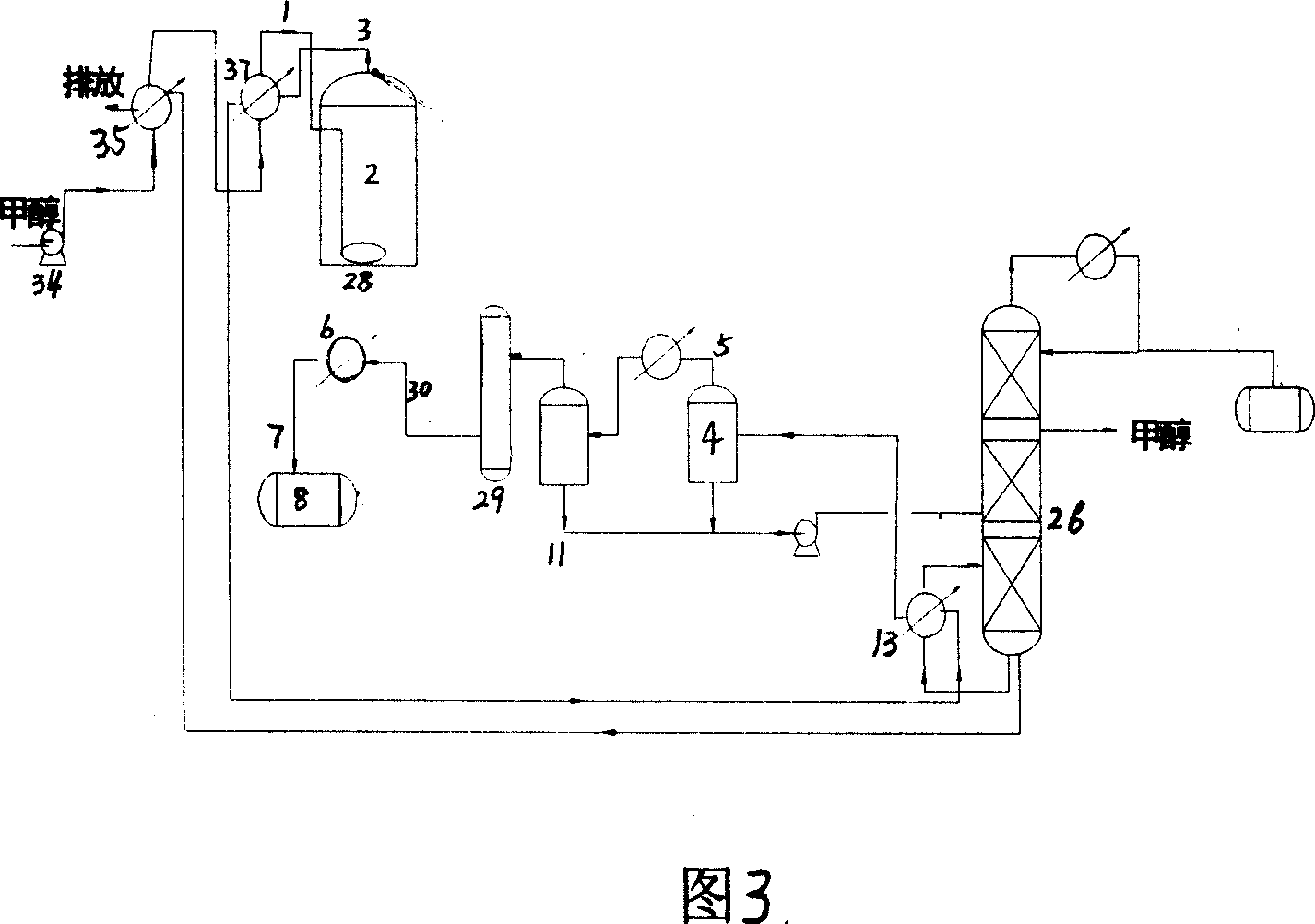

[0038] First put the concentrated sulfuric acid into the bubble column reactor, then heat the concentrated sulfuric acid to 120°C with 1.0Mpa steam, and then feed the methanol with a content of 95% (wt) at a speed of 18t / h through the methanol feed pump. Continuously add to the bubble column reactor until the reaction temperature reaches 220°C and the reactor pressure rises to 0.8Mpa, open the top control valve of the bubble column reactor, and the gas phase passes through the heat exchanger, gas-liquid separator, and dryer And after the condenser, a liquid dimethyl ether product with a content greater than 98.5% is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com