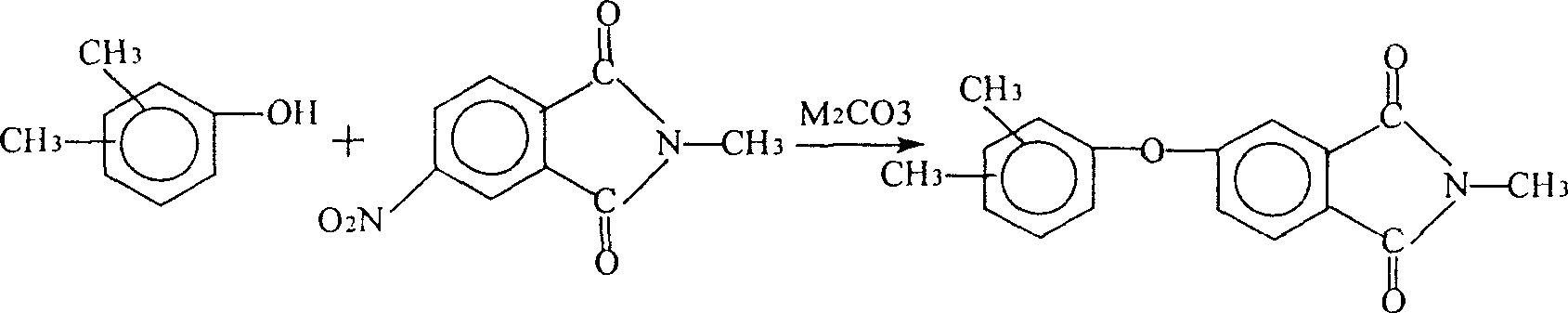

Prepn process of N-methyl-4-(dimethyl phenoxy) phthalimide

A technology of dimethylphenoxy and nitrophthalimide, which is applied in the field of preparation of N-methyl-4-phthalimide, can solve the problems of low product yield, three wastes treatment, cumbersome operation process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Add 680ml of DMAC, 70 grams of 2,3-dimethylphenol, 115 grams of N-methyl-4-nitrophthaloyl in a 1000ml three-necked flask equipped with a stirrer, reflux condenser, inert gas inlet and outlet tubes, and a thermometer. Amine, 44 grams of anhydrous potassium carbonate, 5.4 grams of tetrabutylammonium bromide, under a nitrogen atmosphere, heat and stir to dissolve the solid, raise the temperature to 132 ° C, keep the temperature for 12 hours, and filter the reaction solution while it is hot when the reaction is over , cooling the filtrate to room temperature, standing overnight, and filtering the precipitate to obtain 153.4 grams of N-methyl-4-(2,3-dimethylphenoxy)phthalimide solid crystal product, the color is light yellow, The melting point is 162-163.5°C, and the yield is 94%.

Embodiment 2

[0020] In addition to adding 606ml of DMAC, 120 grams of N-methyl-4-nitrophthalimide, 50 grams of anhydrous potassium carbonate, and 12.6 grams of tetrabutylammonium bromide, and raising the temperature to 131 ° C, other process steps and material ratios And reaction parameters are all identical with embodiment 1, the result obtains 151.5 grams of N-methyl-4-(2,3-dimethylphenoxy) phthalimide light yellow crystalline powder product, fusing point 163~164.5 ℃, obtains The rate is 93%.

Embodiment 3

[0022] Except for adding 2.4 grams of tetrabutylphosphorus bromide and raising the temperature to 135°C, other process steps, material proportions and reaction parameters were the same as in Example 1, resulting in 150.1 grams of N-methyl-4-(2,3- Dimethylphenoxy)phthalimide is a light yellow crystalline powder product with a melting point of 163-165°C and a yield of 92%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com