Method for recovering hydrochloric acid from HCL gas during the production process of benzene sulfochloride

A production process and gas recovery technology, applied in the direction of chlorine/hydrogen chloride, etc., can solve problems such as polluted environment, smog, high treatment costs, etc., and achieve the effects of improving economic benefits, solving environmental protection problems, and solving leakage problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

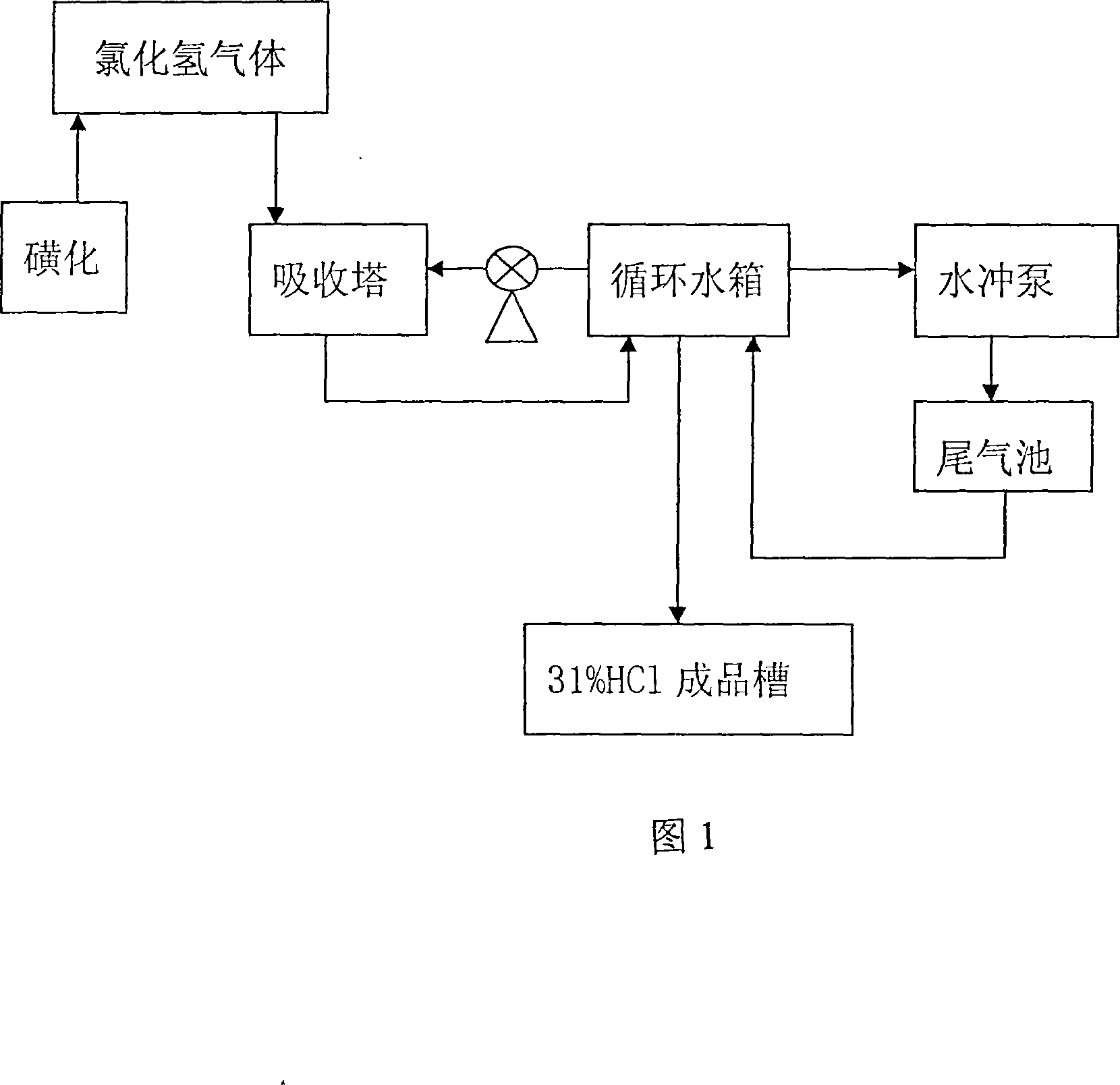

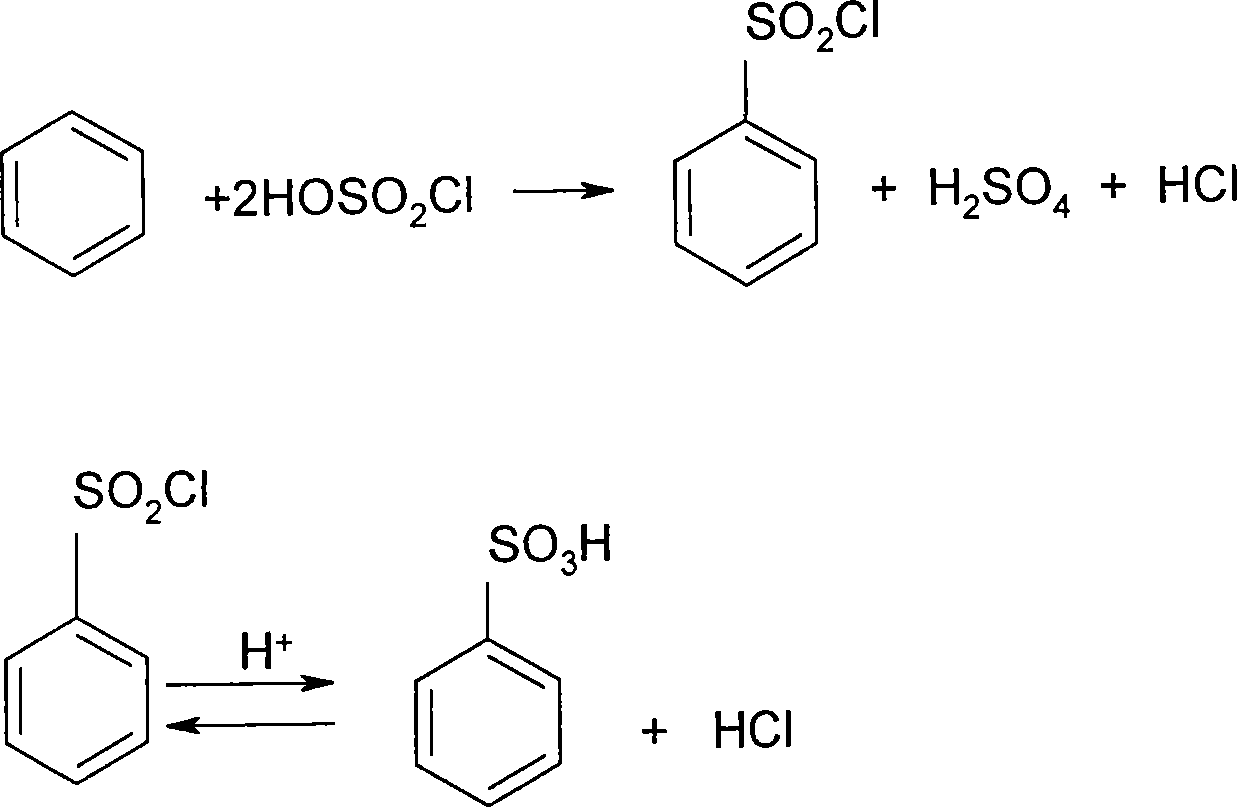

[0008] Hydrogen chloride gas is produced during sulfonation, and hydrogen chloride gas is also produced during dilution (decomposition of benzenesulfonyl chloride and hydrolysis of excess chlorosulfonic acid),

[0009]

[0010] HOSO 2 Cl+H 2 O——H 2 SO 4 +HCl

Embodiment 2

[0012] The main technical and economic indicators and social and economic benefits achieved after implementation.

[0013] Quality indicators of benzenesulfonyl chloride products: benzenesulfonyl chloride content ≥ 99.0%, free acid ≤ 0.08%, diphenyl sulfone ≤ 0.10%, chromaticity 25-20; after adopting a new process, not only the leakage problem is solved, but also the A large amount of waste hydrochloric acid cannot be recycled and used, but can only be discharged as wastewater, which not only causes a lot of pollution, but also increases the cost of treatment and improves economic benefits after entering the wastewater treatment station. The recovered hydrochloric acid with a concentration of 31% can increase the economic benefit of nearly 1 million yuan.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com