Acidic copper-containing etching liquid treatment method and system

A technology of copper etching and liquid treatment, applied in the direction of copper sulfate, filtration treatment, precipitation treatment, etc., can solve the problems of low current efficiency of electrolytic cell, frequent replacement of ion membrane, high maintenance cost of equipment, etc. Fast speed, realize the effect of comprehensive utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

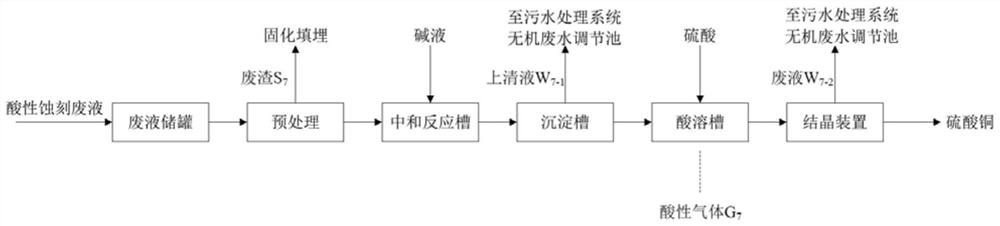

[0041] As a method for treating acidic copper-containing etching solution according to an embodiment of the present invention, the method comprises the following steps:

[0042] (1) Carry out solid impurity removal pretreatment and degreasing pretreatment to described acidic copper-containing etching liquid, the waste residue that described solid impurity removal pretreatment produces is through incineration treatment or landfill treatment, and the acidic copper-containing etching solution after pretreatment Adding hydrochloric acid with a mass concentration of 20% to 30% to the etching solution to adjust the pH to 0.1, adding sodium chlorate to oxidize the copper in the acidic copper-containing etching solution to divalent copper ions, and obtain a mixed system A;

[0043] (2) adding alkali to the mixed system A to adjust the pH of the mixed system A to be 7.5 to 8 to convert the divalent copper ions in the mixed system A into copper hydroxide precipitation; solid-liquid separ...

Embodiment 2

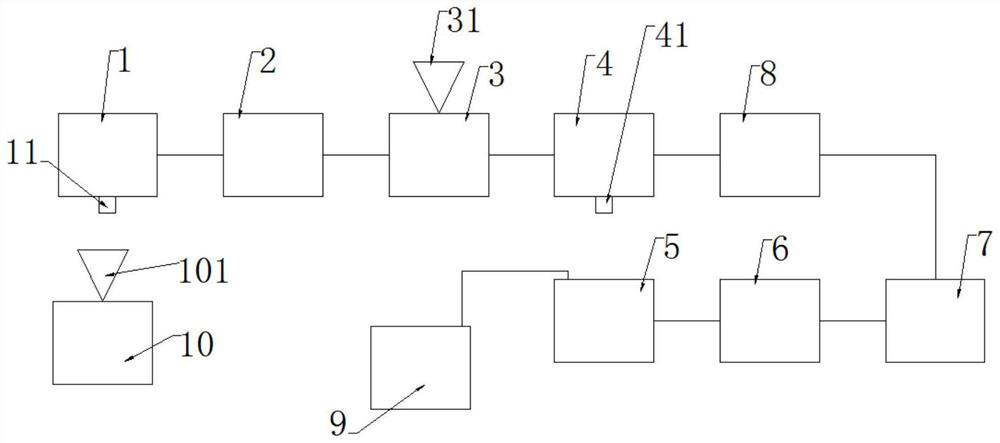

[0053] As an acidic copper-containing etching solution treatment system according to an embodiment of the present invention, the acidic copper-containing etching solution treatment system includes a solid-liquid separation device 1, an oil-water separation device 2, a reaction tank 3 and a filter press connected in sequence. Device 4, the filter press device 4 has a liquid outlet and a solid outlet 41, an acid-dissolving tank 5 is arranged below the solid outlet 41 of the filter press device 4, and the acid-dissolving tank 5 is successively connected with the crystallization device 6 and the three-effect evaporation The device 7 is in pipeline communication.

[0054] The system structure of this embodiment is simple and occupies a small area. Through the improvement of the connection relationship, the acidic copper-containing etching solution is used to remove solid impurities, remove oil, and perform oxidation and precipitation reactions. After the precipitation produces copp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com