Method for preparing chloramphenicol from 4-chloro-benzaldehyde

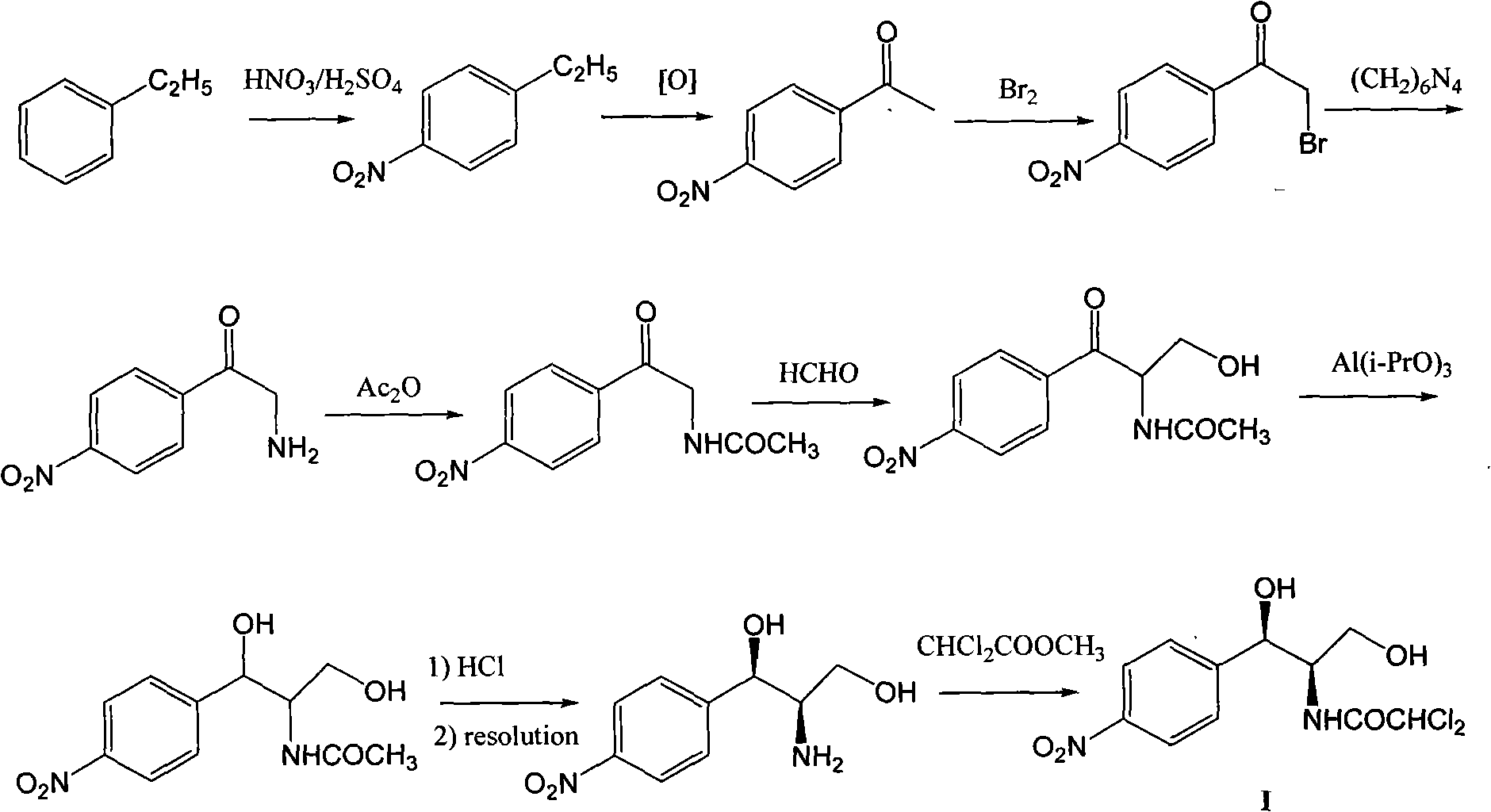

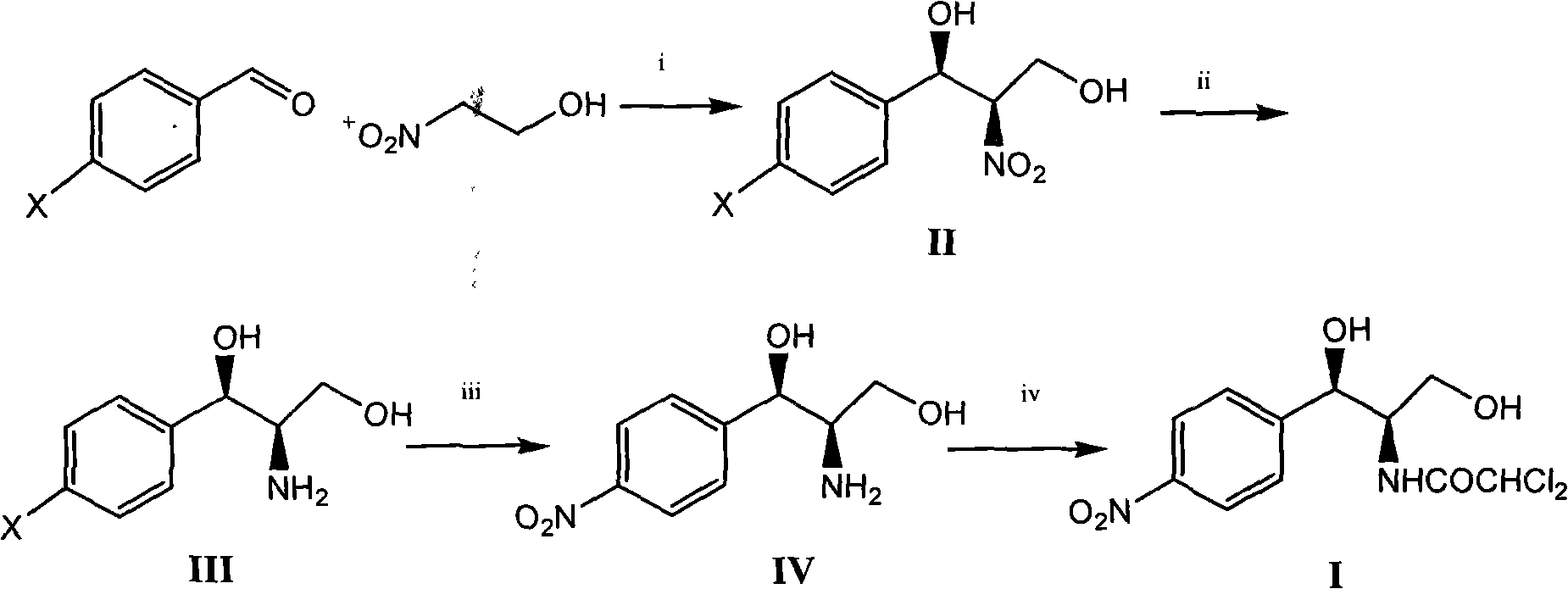

A technology of chloramphenicol and chlorophenyl, which is applied in the field of compound preparation, can solve the problems of long synthetic route of chloramphenicol, production cost and increase of three wastes, etc., achieves easy availability and low price of raw materials, solves the problem of three wastes and yields high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The preparation of embodiment 1 (1R, 2R)-2-nitro-1-(4-chlorophenyl)-1,3-propanediol

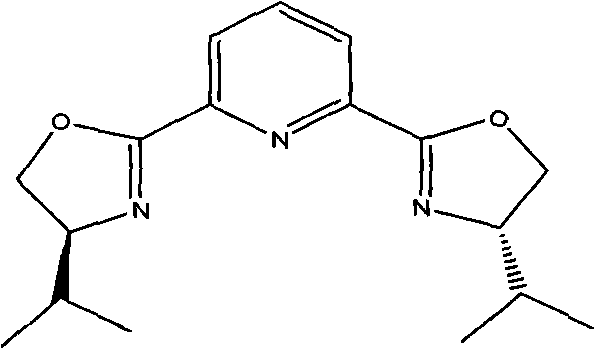

[0035] 1.8 g of Cu(OTf) 2 (0.50mmol), 2.4 grams of ligand (5.2mmol) and 40 milliliters of 1,4-dioxane were added in a 250 milliliter single-necked flask, and the nitrogen flow was kept constant after replacing the air inside with nitrogen, and at room temperature, magnetically stirred for 2 After one hour, cool with an ice bath, add 7.0 grams of 4-chlorobenzaldehyde (50mmol), 45.5 grams of 2-nitroethanol (500mmol) and N-methylmorpholine (0.54 milliliters, 5.0mmol) successively, and the reaction solution is placed in an ice bath Stir at 0 to 5°C for about 24 hours. After no raw material 4-chlorobenzaldehyde spots are detected by thin-plate chromatography, the volatile solvent is removed by distillation under reduced pressure, the catalyst is removed by silica gel filtration, and the filtrate is concentrated to obtain 10.6 grams of the product, with a yield of 91.8%. , HPLC measured e.e...

Embodiment 2

[0036] Example 2 Preparation of (1R, 2R)-2-nitro-1-(4-chlorophenyl)-1,3-propanediol 2

[0037] 0.8 g of Cu(OTf) 2 (0.50mmol), 0.8 gram of rhodium acetate, 1.2 gram of 2,6-bis[(S)-4-isopropyl-1-phenyl-4,5-dihydro-1H-2-imidazolyl]pyridine (5.2 mmol) and 20 milliliters of 1,4-dioxane were added in a 250 milliliter single-necked flask, and the nitrogen flow was kept constant after replacing the air inside with nitrogen. At room temperature, magnetically stirred for 2 hours and then cooled with an ice bath, and then added 7.0 grams of 4-Chlorobenzaldehyde (50mmol), 45.5 grams of 2-nitroethanol (500mmol) and 0.15 grams of picoline, the reaction solution was stirred in an ice bath at 4°C for about 20 hours, and no raw material 4-chlorobenzaldehyde was detected by thin-plate chromatography After spotting, the volatile solvent was then distilled off under reduced pressure, the catalyst was removed by silica gel filtration, and the filtrate was concentrated to obtain 10.9 grams of prod...

Embodiment 3

[0038] Example 3 Preparation of (1R, 2R)-2-nitro-1-(4-chlorophenyl)-1,3-propanediol 3

[0039] 1.8 g of Cu(OTf) 2(0.50mmol), 2.4 grams of 2,6-bis[(S)-4-isopropyl-1-phenyl-4,5-dihydro-1H-2-imidazolyl]pyridine (5.2mmol) and 40 ml Add 1,4-dioxane into a 250 ml single-necked flask, replace the air inside with nitrogen and keep the nitrogen flow constant. At room temperature, stir magnetically for 2 hours and cool in an ice bath, then add 6.0 g of 4-bromobenzaldehyde in turn , 45.5 grams of 2-nitroethanol (500mmol) and N-methylmorpholine (0.54 milliliters, 5.0mmol), the reaction solution was stirred in an ice bath at 4°C for about 30 hours, and no raw material 4-chlorobenzaldehyde was detected by thin plate chromatography After spotting, the volatile solvent was then distilled off under reduced pressure, the catalyst was removed by silica gel filtration, and the filtrate was concentrated to obtain 9.6 grams of product, with a yield of 86.2%. The e.e value of HPLC was 92.9%. 1H), ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| specific rotation | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com