Patents

Literature

42results about How to "Good value for industrial production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Oscilloscope

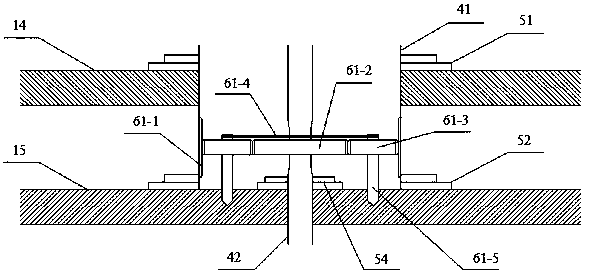

ActiveCN104020331AEasy to carryEasy to useDigital variable/waveform displaySignal modulationCollections data

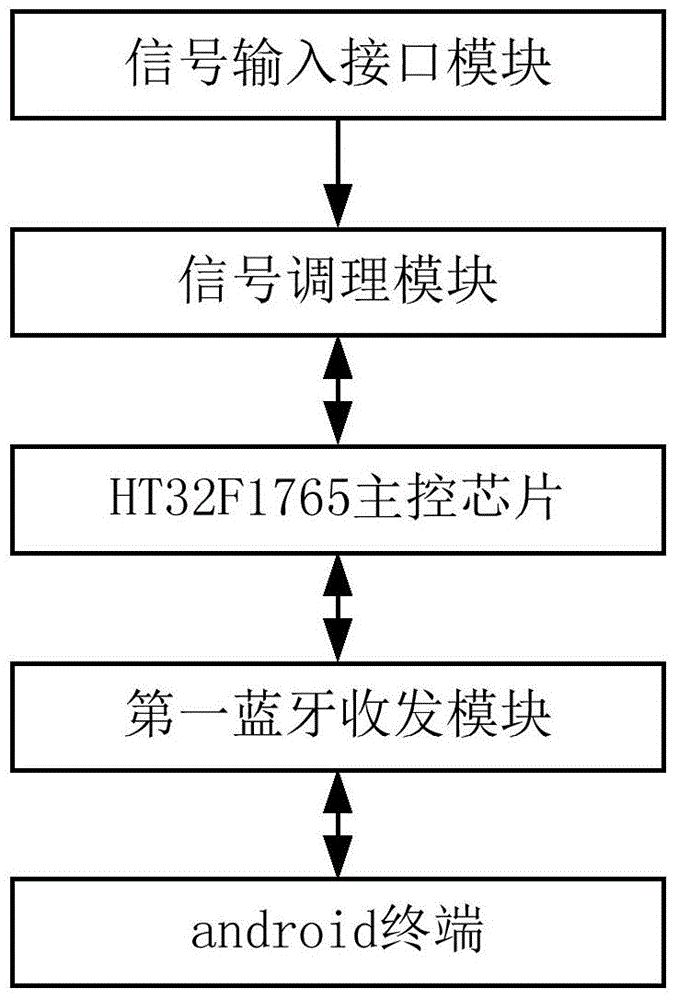

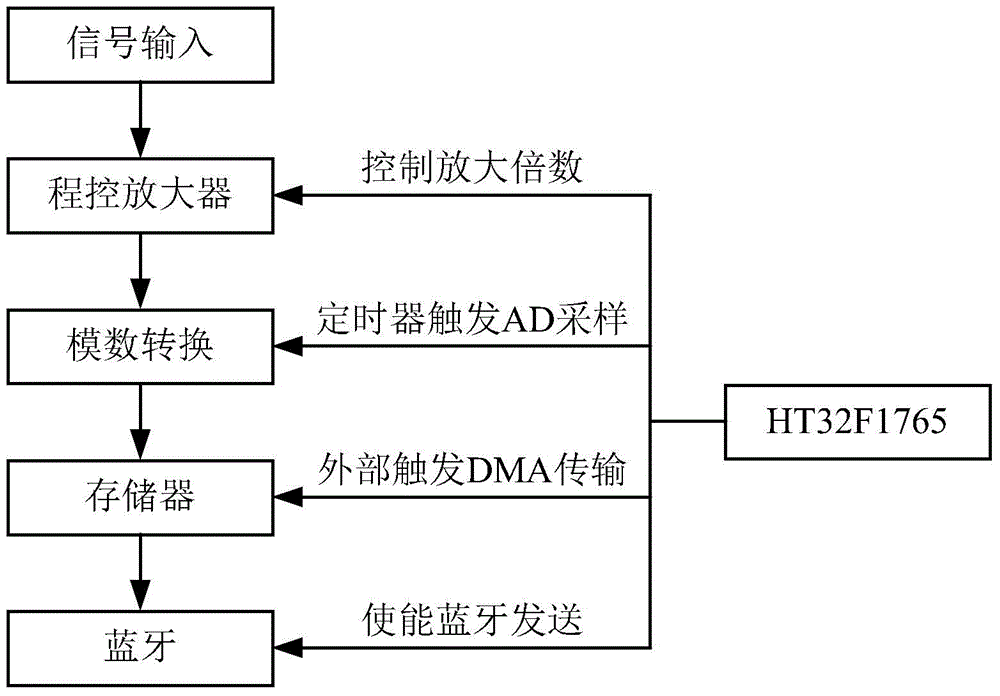

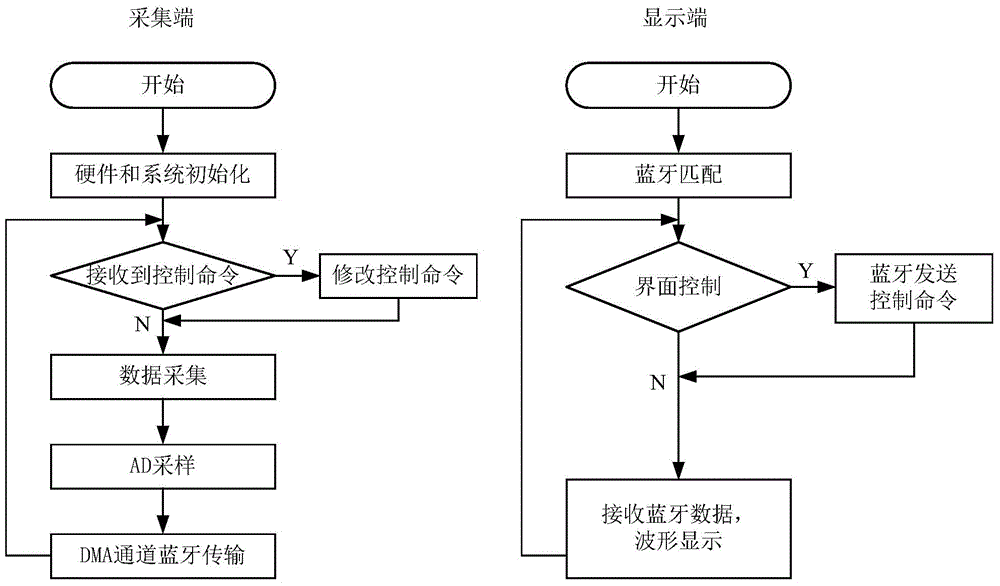

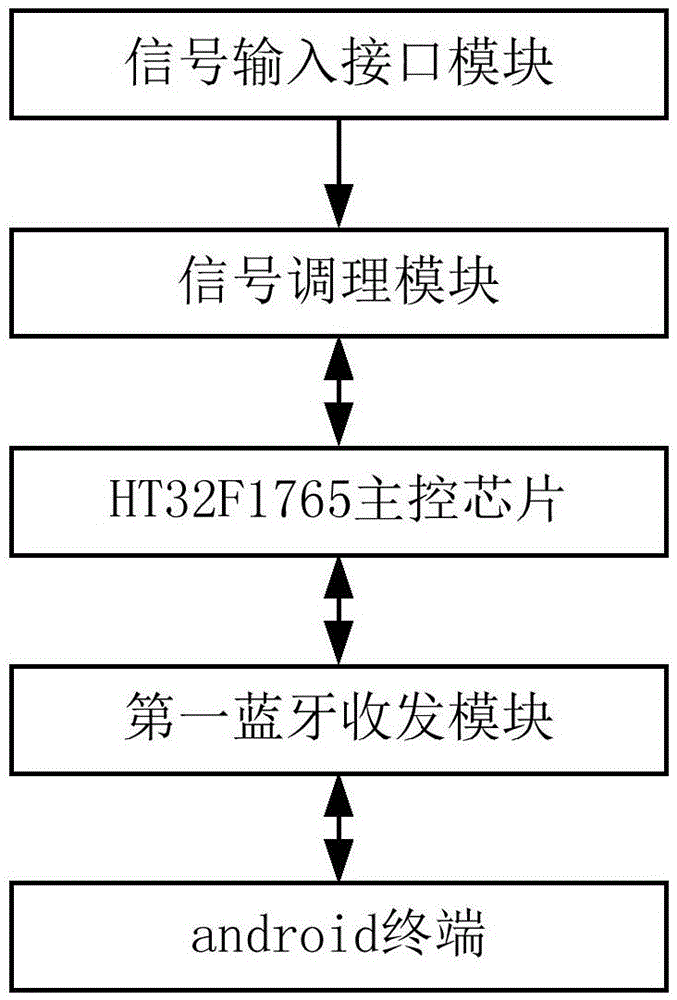

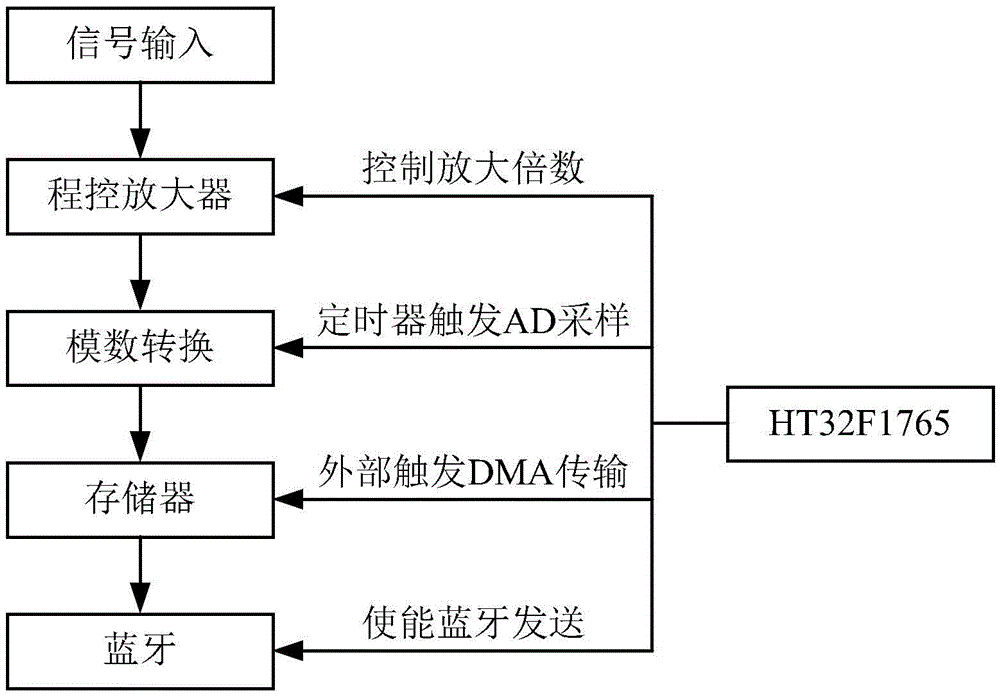

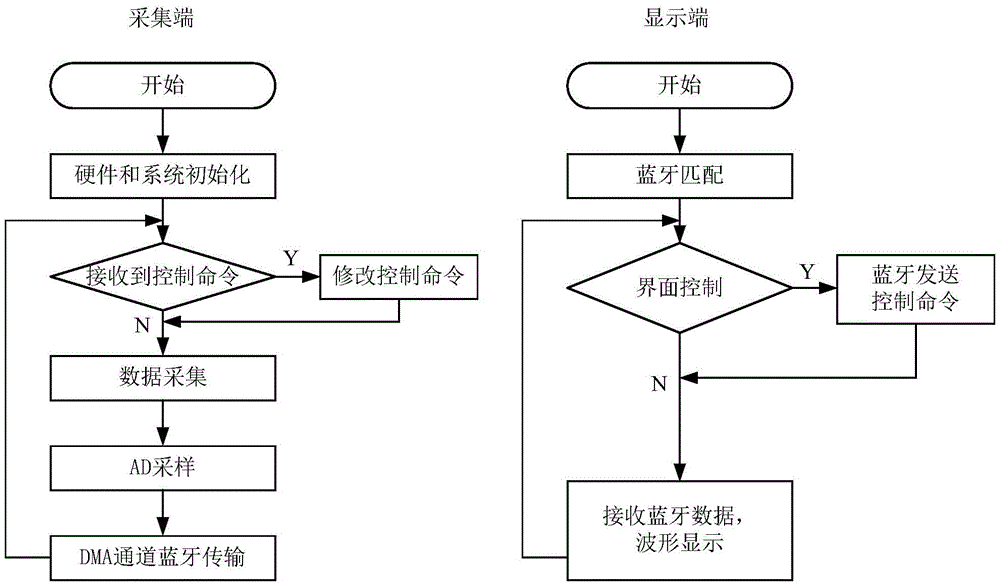

The invention discloses an oscilloscope. The oscilloscope comprises a collection end and a display end; the collection end comprises a signal input interface module, a signal modulation module, a data collection module, a charging module and a first wireless receiving-transmitting module; the display end comprises a second wireless receiving-transmitting module, a waveform display module and a waveform control module; the charging module is respectively connected with the signal input interface module, the signal modulation module, the data collection module and the first wireless receiving-transmitting module; the signal input interface module, the signal modulation module, the data collection module and the first wireless receiving-transmitting module are sequentially connected; the first wireless receiving-transmitting module is connected with the second wireless receiving-transmitting module in a wireless manner; the second wireless receiving-transmitting module, the waveform display module and the waveform control module are sequentially connected.

Owner:广东威而信实业有限公司

Compound amlodipine and valsartan solid preparation and preparation method thereof

InactiveCN101744813AEasy to operateGood value for industrial productionPharmaceutical product form changeCapsule deliveryValsartanMedicine

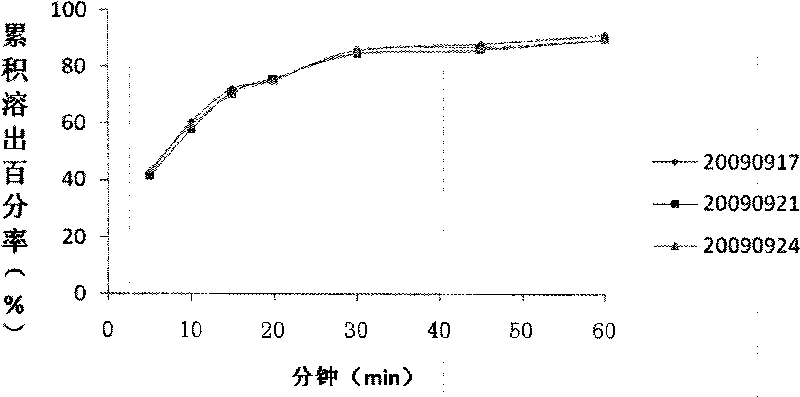

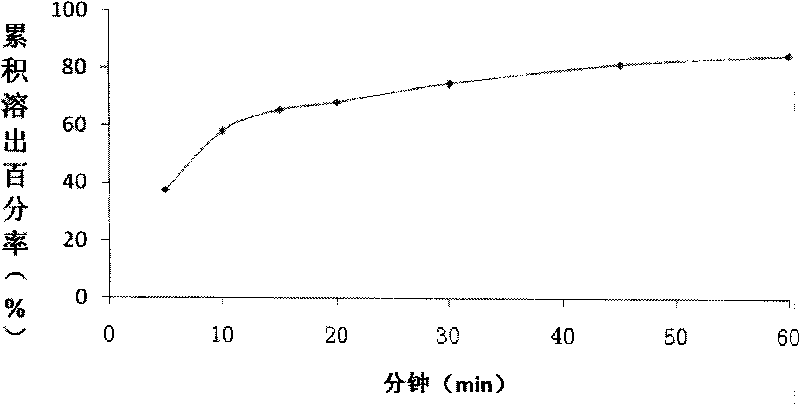

The invention discloses a compound amlodipine and valsartan solid preparation and a preparation method thereof. The preparation can be a tablet or a capsule and contains 2.5-10g of amlodipine or pharmaceutically acceptable salt thereof (calculated according to the amlodipine) and 40-640g of valsartan or pharmaceutically acceptable salt thereof (calculated according to the valsartan). The preparation method of the compound amlodipine and valsartan solid preparation comprises the steps of mixing the two medicines and the corresponding medicinal auxiliary materials according to the proportion, mixing with the corresponding lubricant or glidant after granulating in a wet method, and pressing into a tablet or filling into a capsule so as to obtain the compound amlodipine and valsartan solid preparation. In the invention, the tablet or the capsule is prepared after the two active substances with unequal doses are granulated in the wet method, and the method is simple and convenient, is easy to control the quality and is suitable for the industrialized production. More than 85% of the amlodipine in the preparation is dissolved out within 30 minutes, and the invention has favorable market popularization prospect.

Owner:YANGTZE RIVER PHARM GRP CO LTD

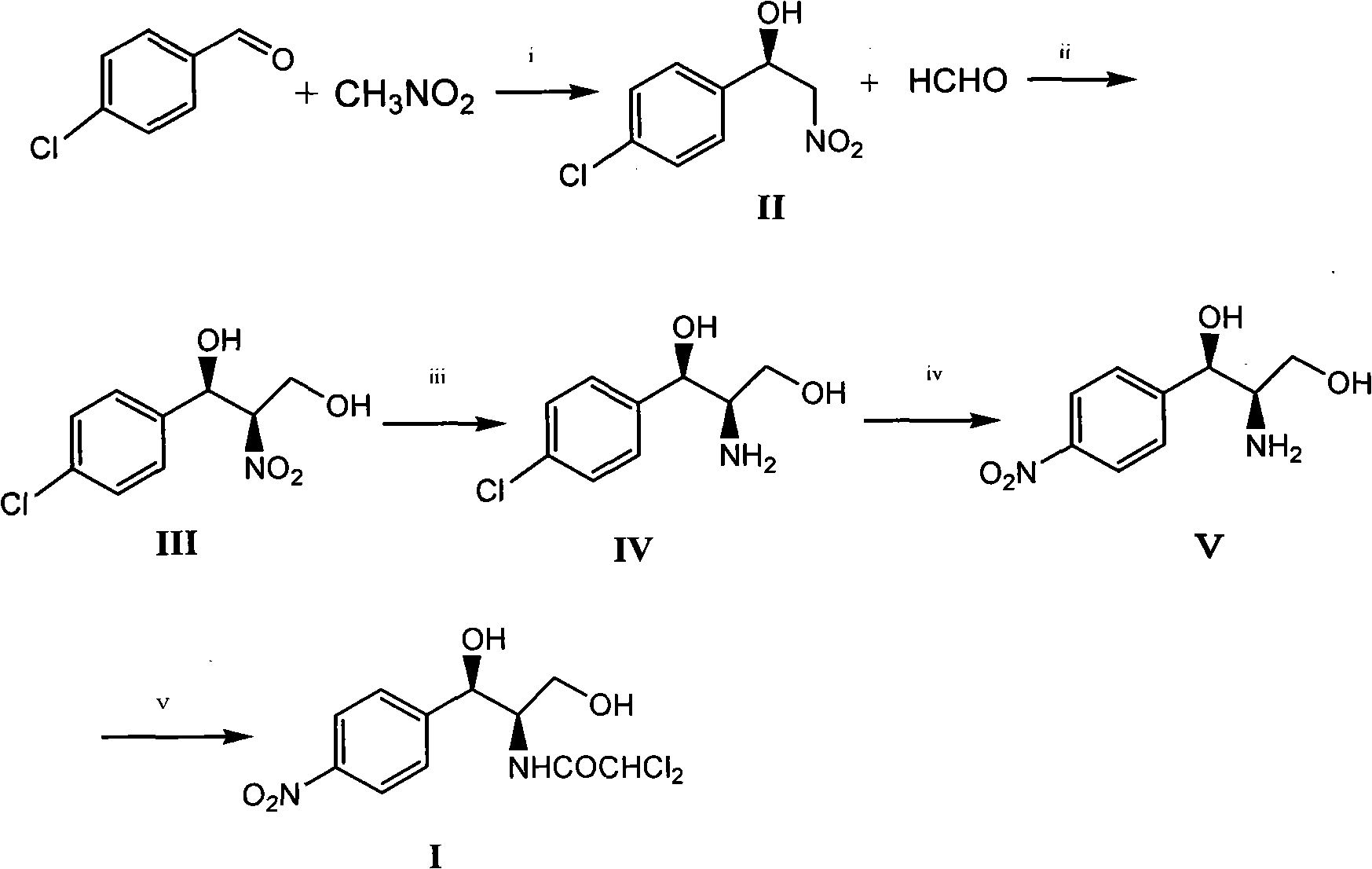

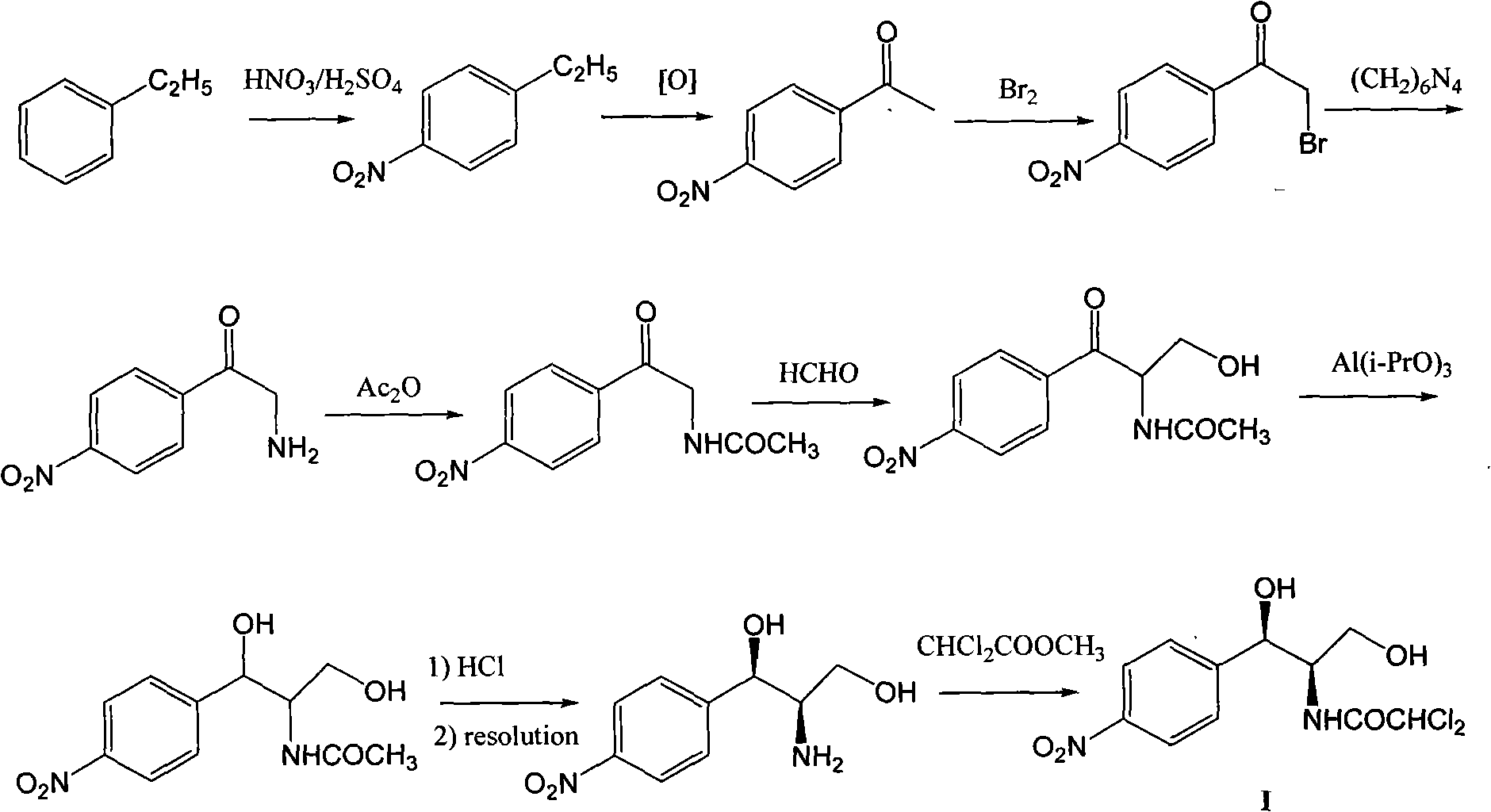

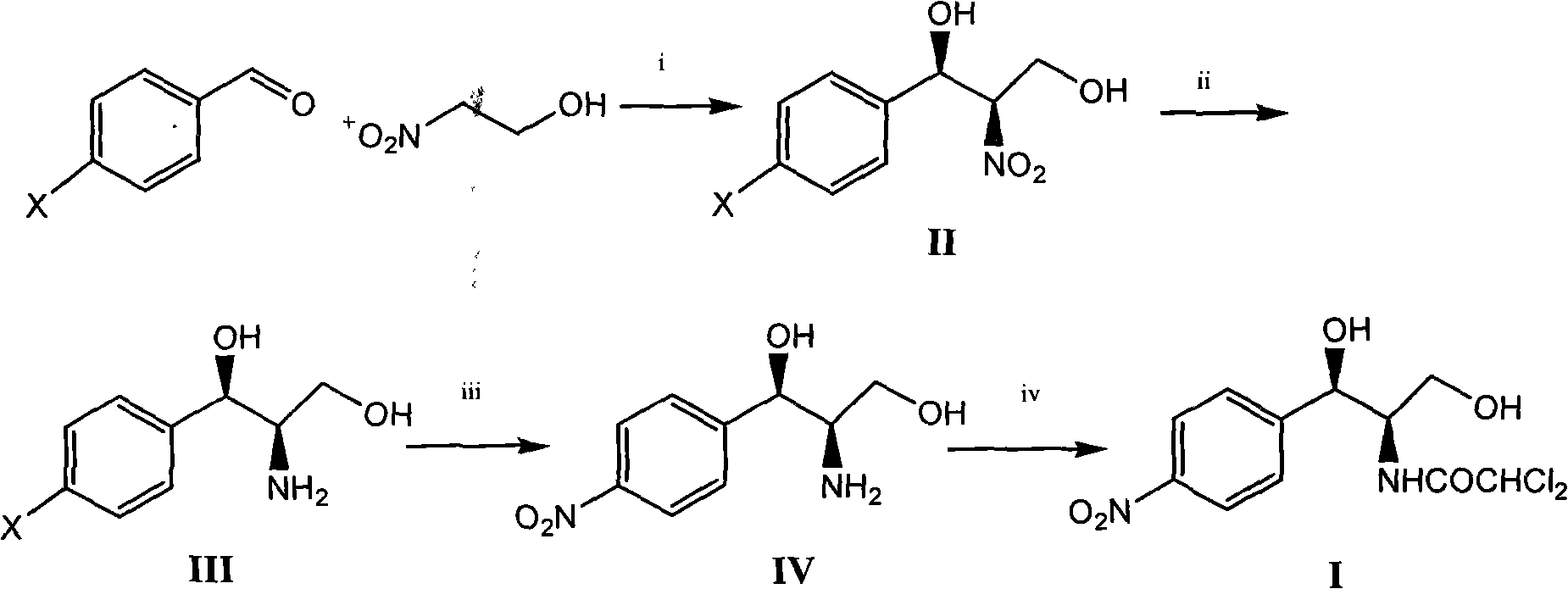

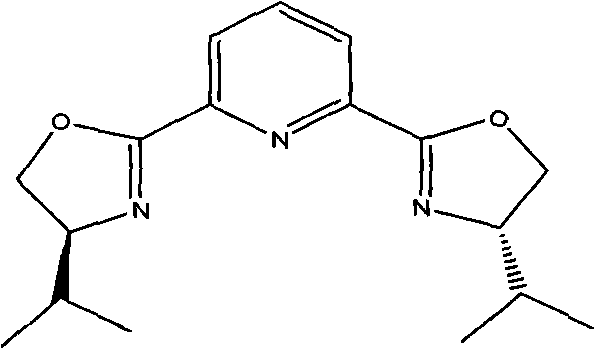

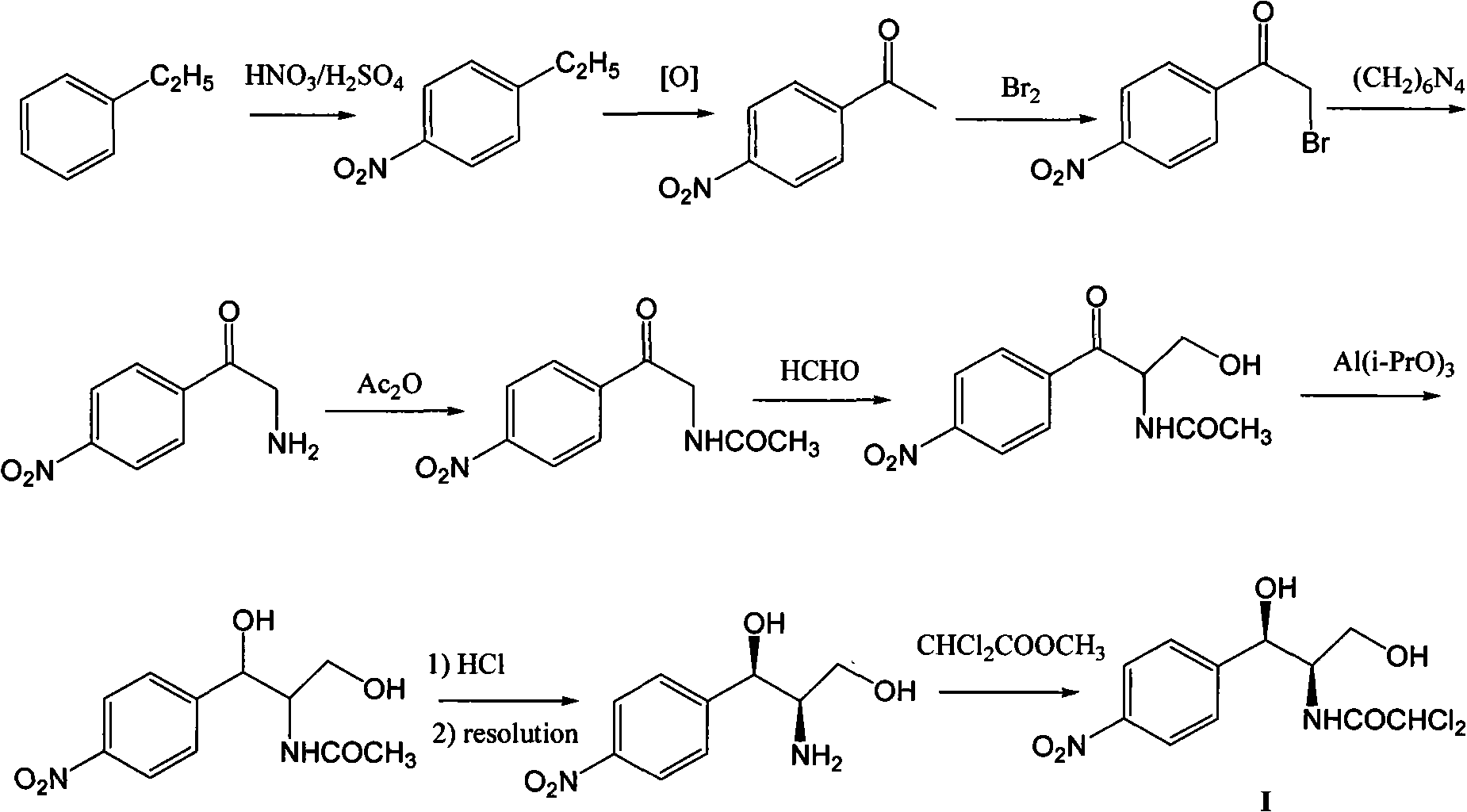

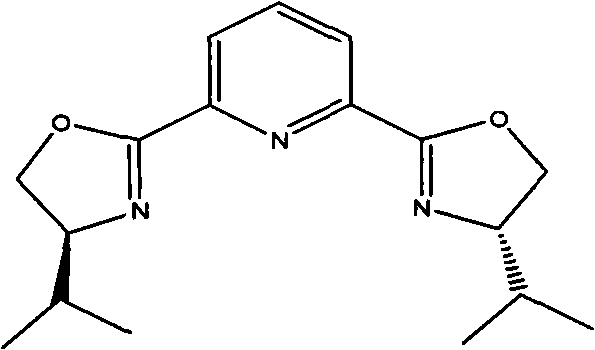

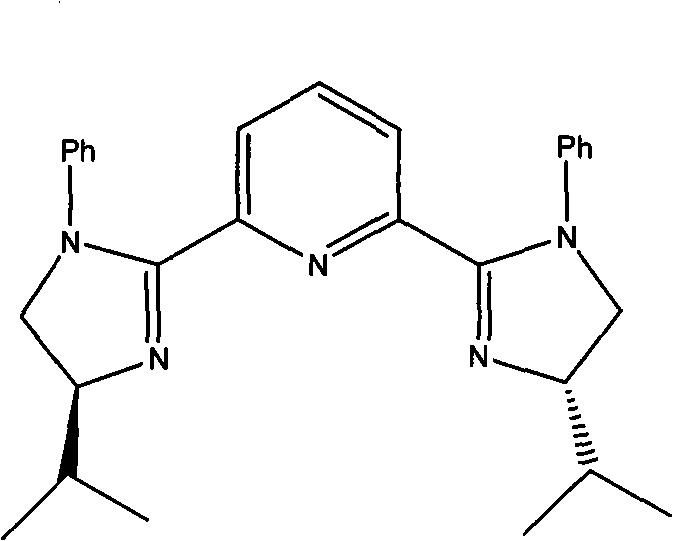

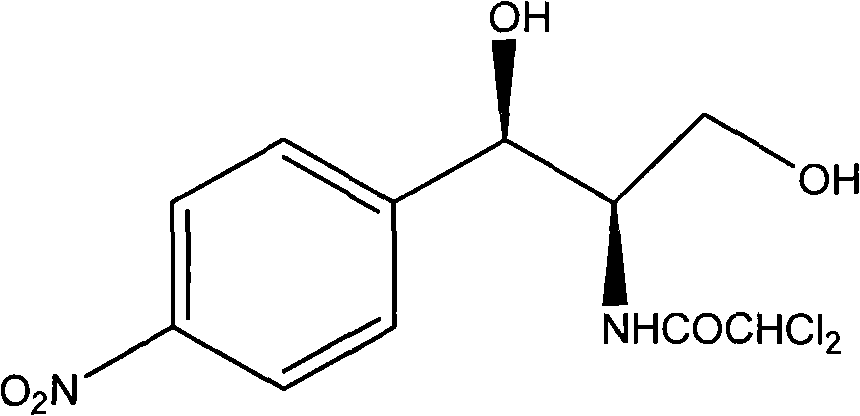

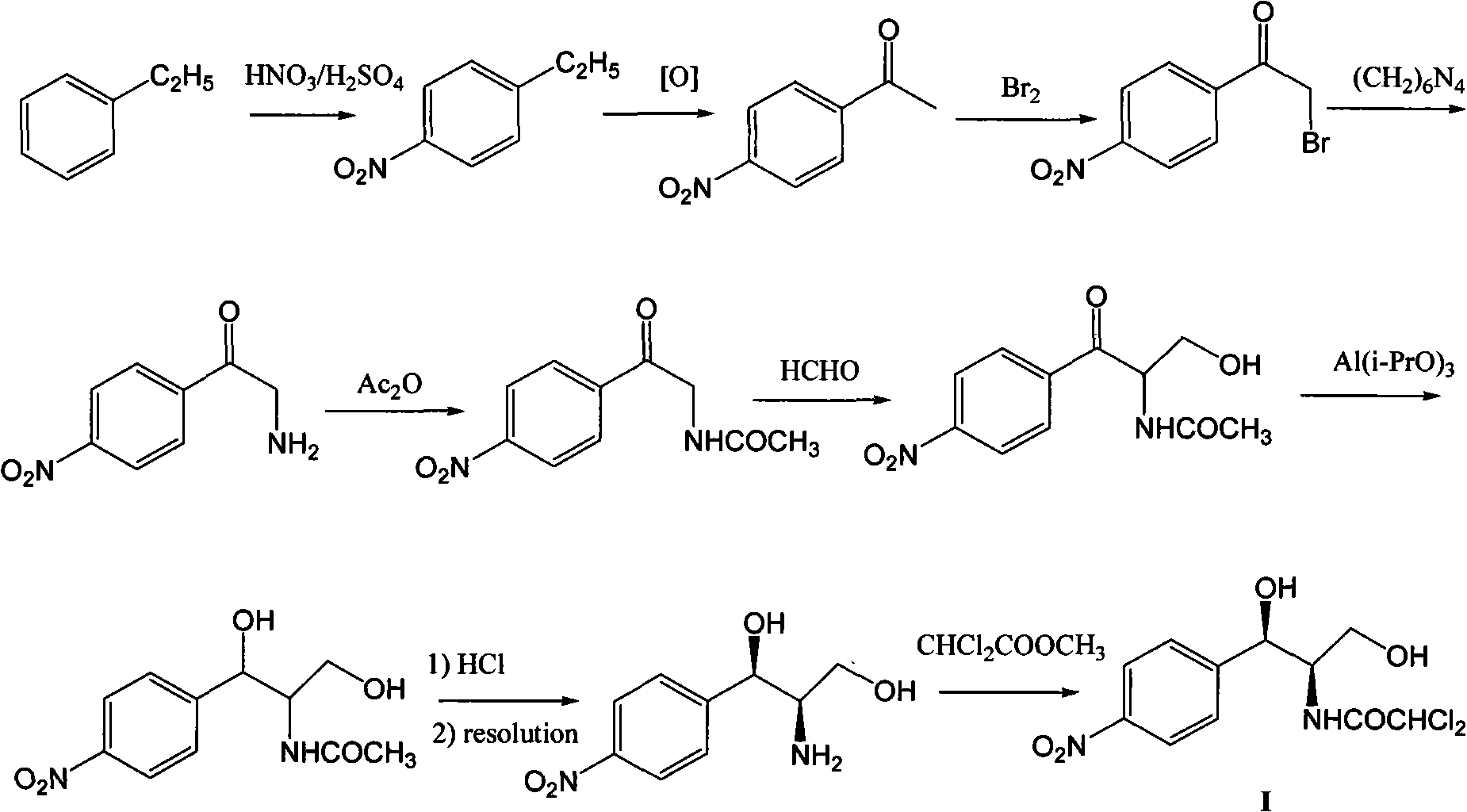

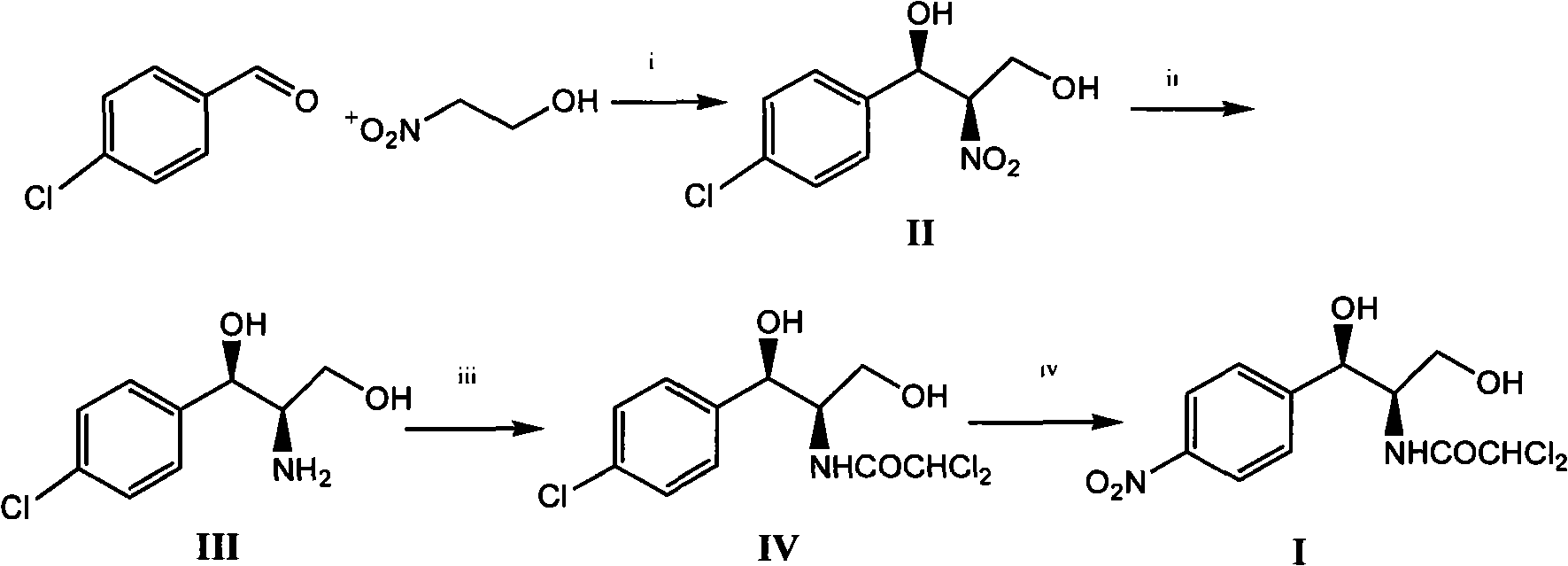

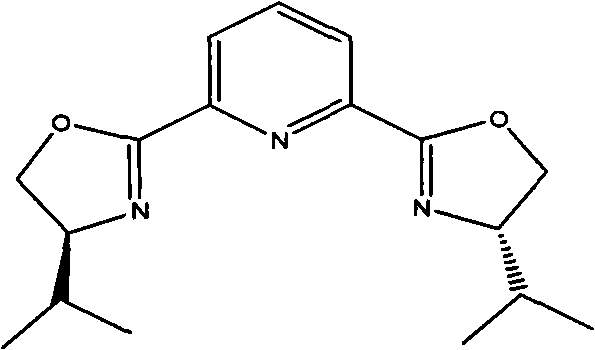

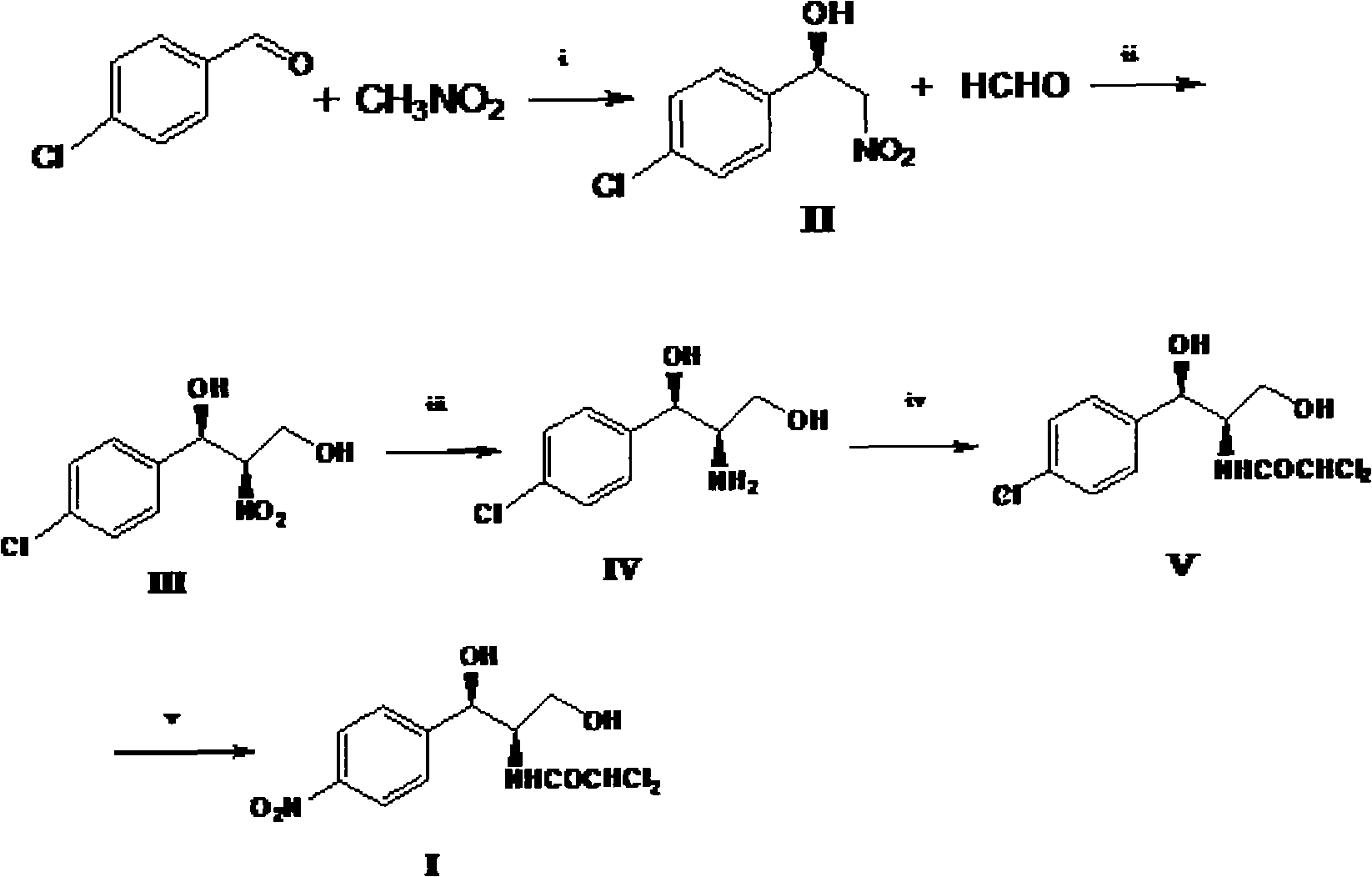

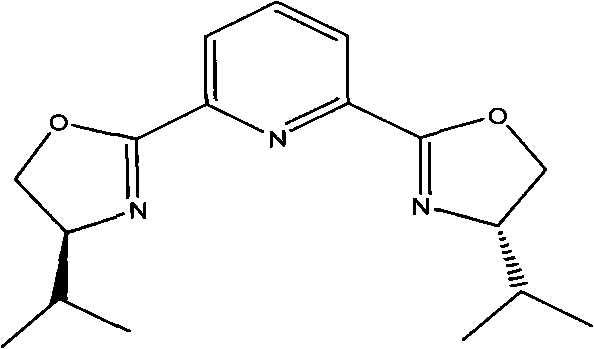

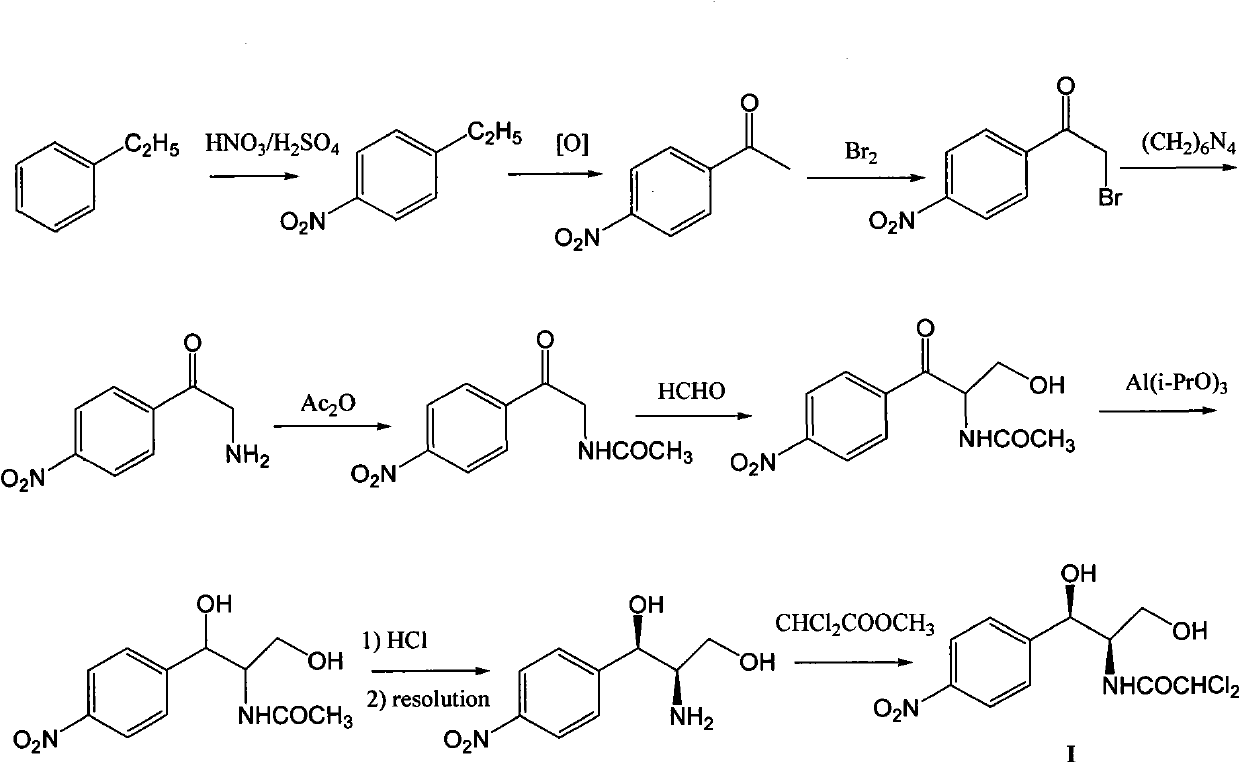

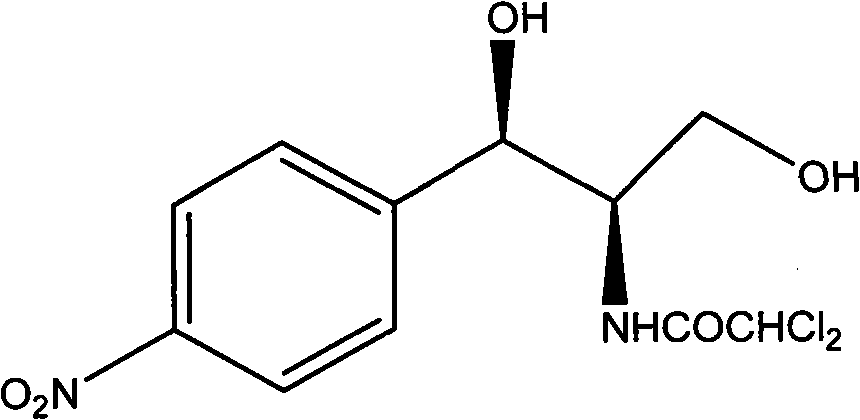

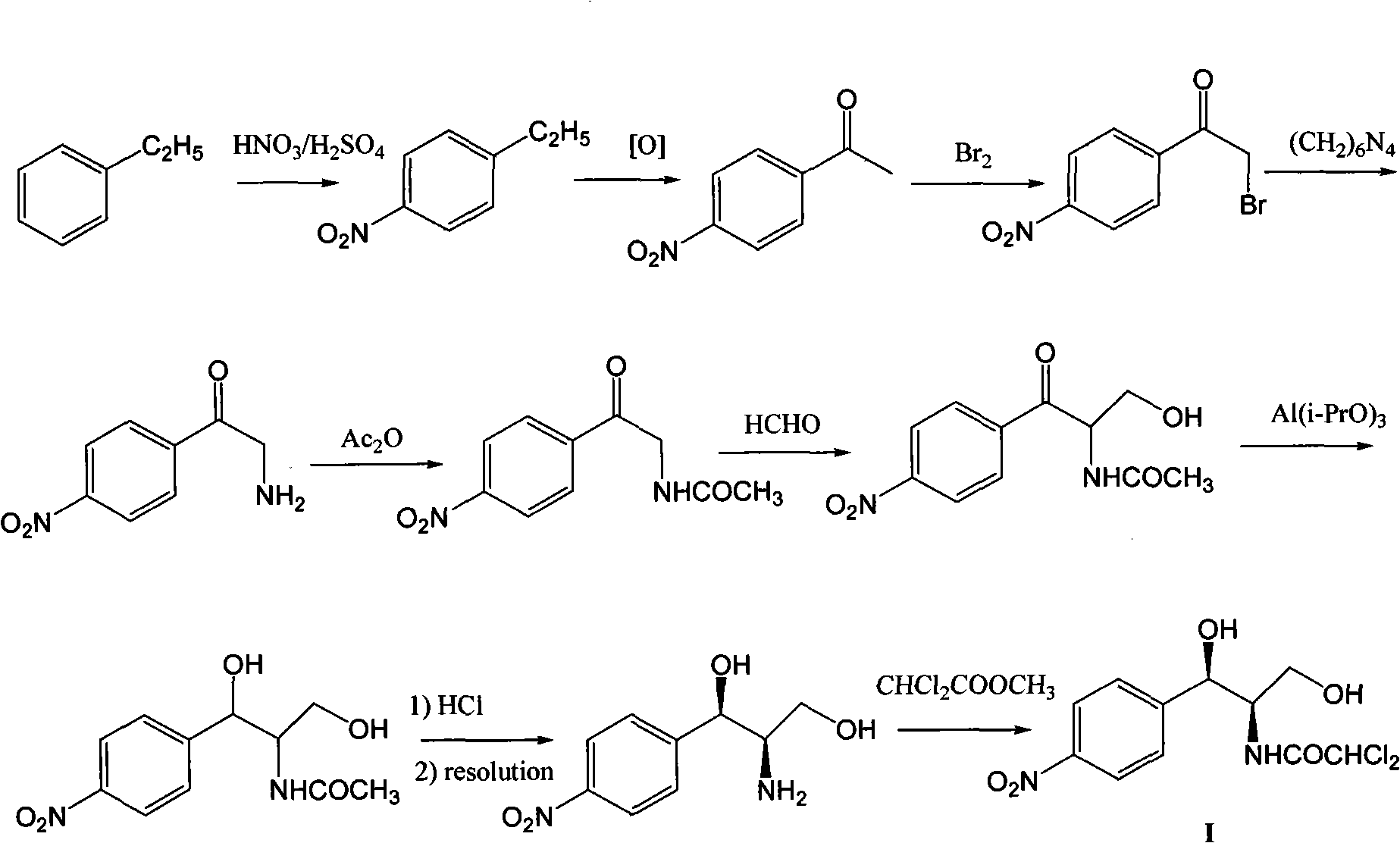

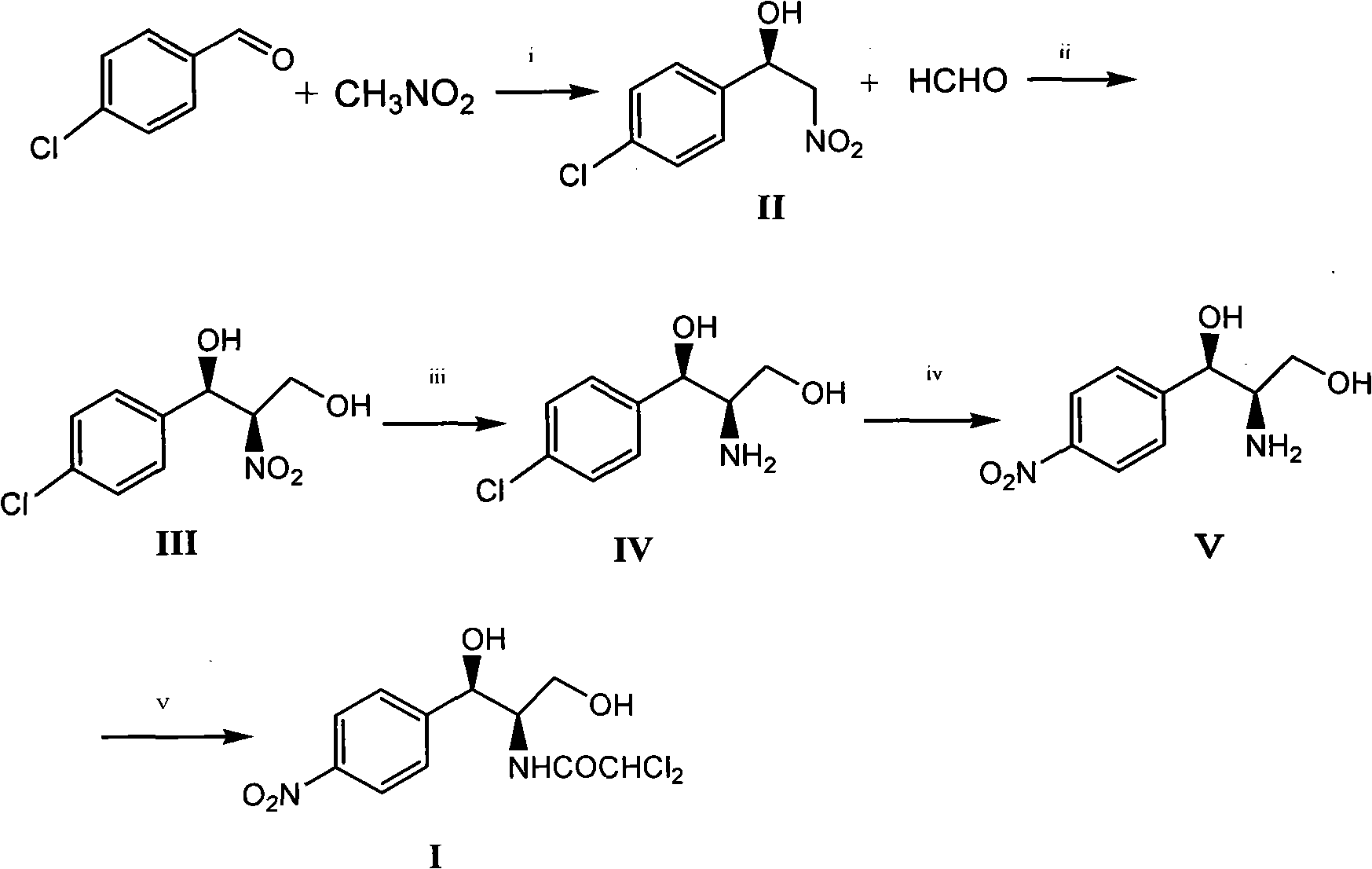

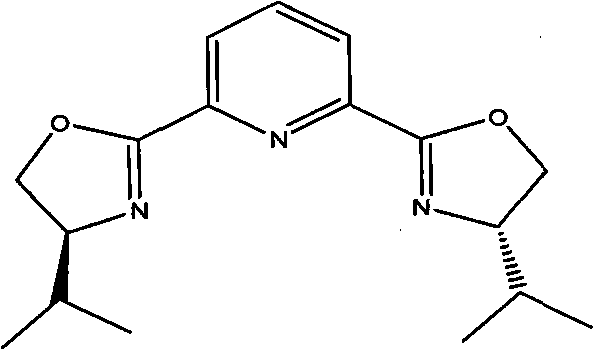

Method for synthesizing chloramphenicol from nitromethane

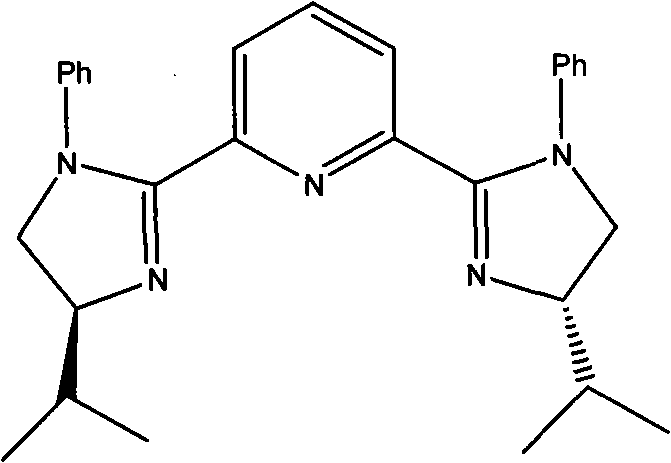

ActiveCN102399164ARaw materials are cheap and easy to getAvoid splittingOrganic compound preparationCarboxylic acid amides preparationP-chlorobenzaldehydeNitromethane

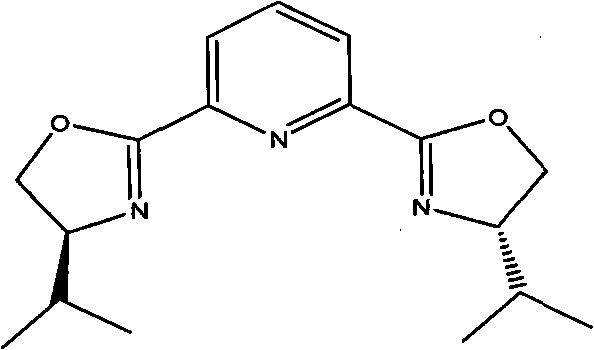

The invention relates to a method for synthesizing a broad spectrum antibiotic of chloramphenicol. The method comprises the following steps of: synthesizing (R)-2-nitro-1-(4-chlorophenyl)ethanol by using p-chlorobenzaldehyde and nitromethane as raw materials in the presence of a chiral catalyst; reacting with formaldehyde to obtain (1R,2R)-2-nitro-1-(4-chlorophenyl)-1,3-propanediol, and performing catalytic hydrogenation to obtain (1R,2R)-2-amino-1-(4-chlorophenyl)-1,3-propanediol; and performing nitro substitution and dichloro acetylization on the intermediate to obtain the chloramphenicol. By the method, the common chiral resolution and aluminum isopropoxide reduction in the industry at present can be avoided, three wastes are reduced, the raw materials and reagents are cheap and readily available, the method comprises a few synthesizing steps, the yield is high, and the method is more suitable for industrial production.

Owner:WUHAN WUYAO SCI & TECH

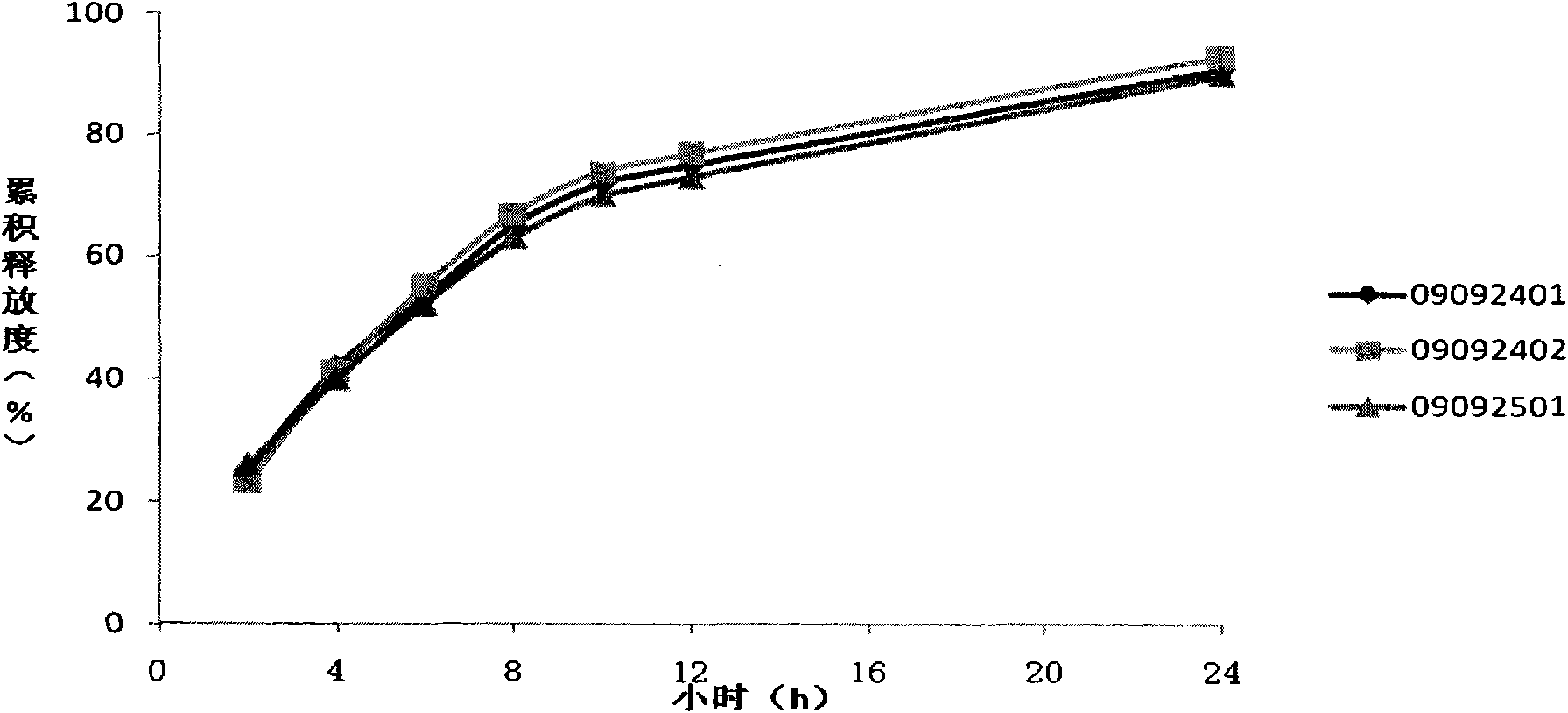

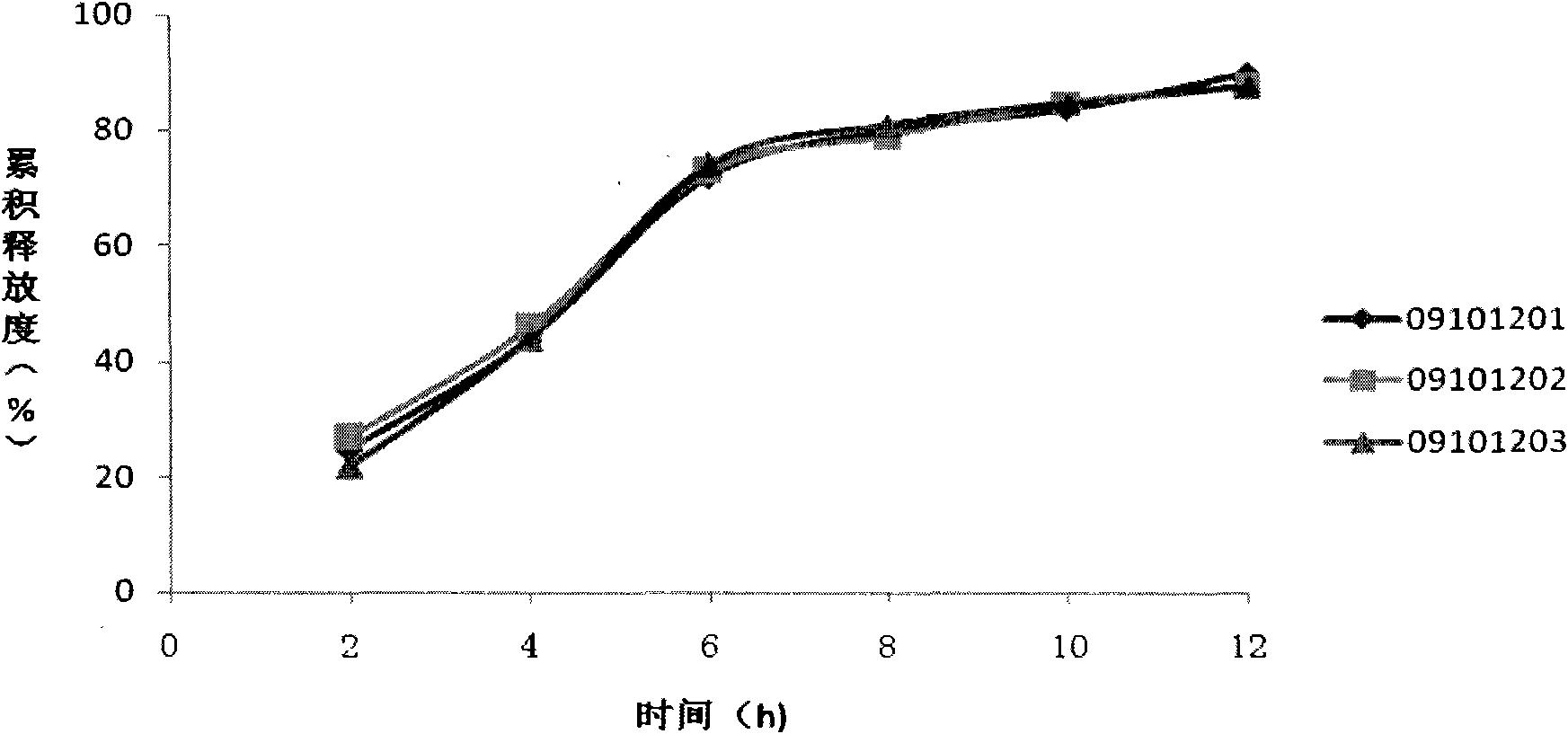

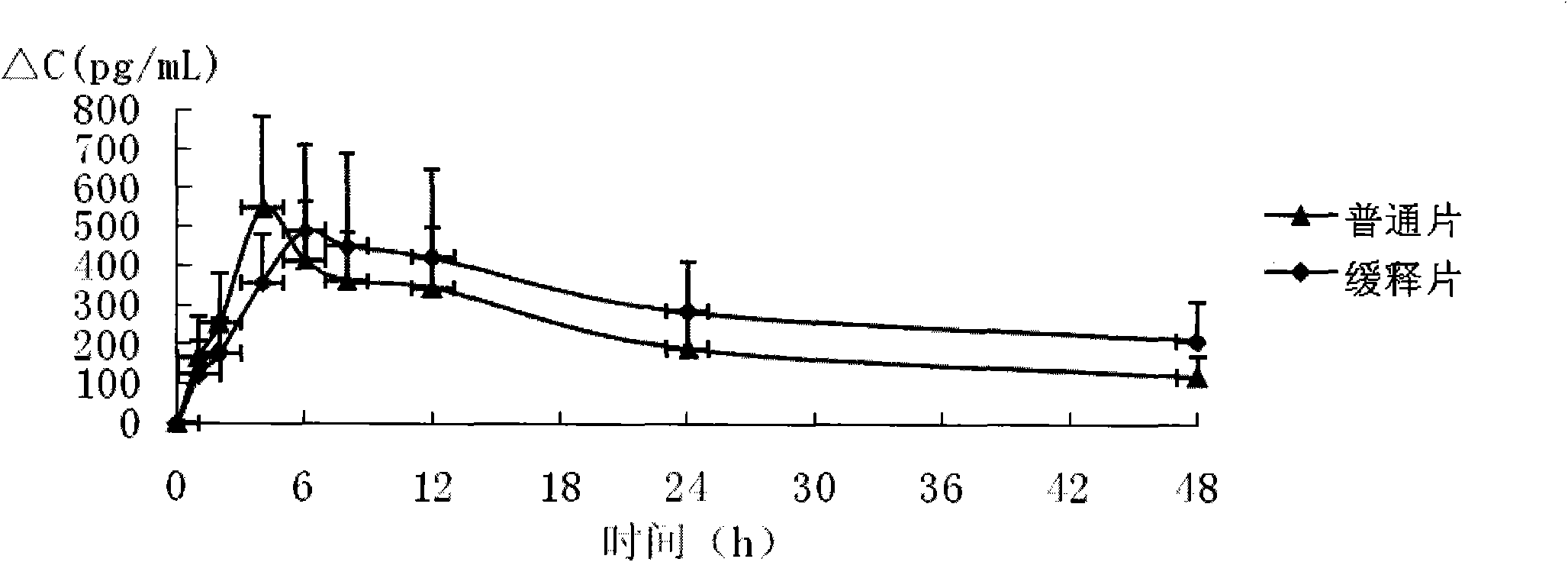

Mecobalamin sustained-release tablet and preparation method thereof

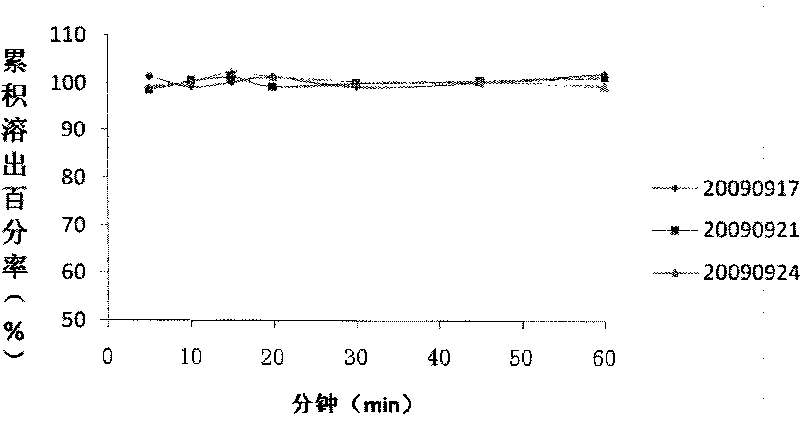

ActiveCN101856336AGood value for industrial productionImprove bioavailabilityOrganic active ingredientsNervous disorderPatient complianceQuality control

The invention discloses a mecobalamin sustained-release tablet and a preparation method thereof. The preparation is a sustained-release tablet containing mecobalamin. The preparation method is to mix mecobalamin, the corresponding slow-releasing material and other accessories and tabletting to obtain the finished product. In the method, mecobalamin is used to prepare the sustained-release tablet,thus solving the problem that the common mecobalamin preparation is poor to absorb, improving drug absorption and increasing bioavailability; and the method is simple, quality control is easy to perform, and the method is suitable for industrial production. Mecobalamin in the preparation is released slowly in 12h or 24h and the tablet is taken once or twice every day, thus the dosing frequency can be reduced, the patient compliance can be improved and the blood concentration can be better balanced.

Owner:YANGTZE RIVER PHARM GRP CO LTD

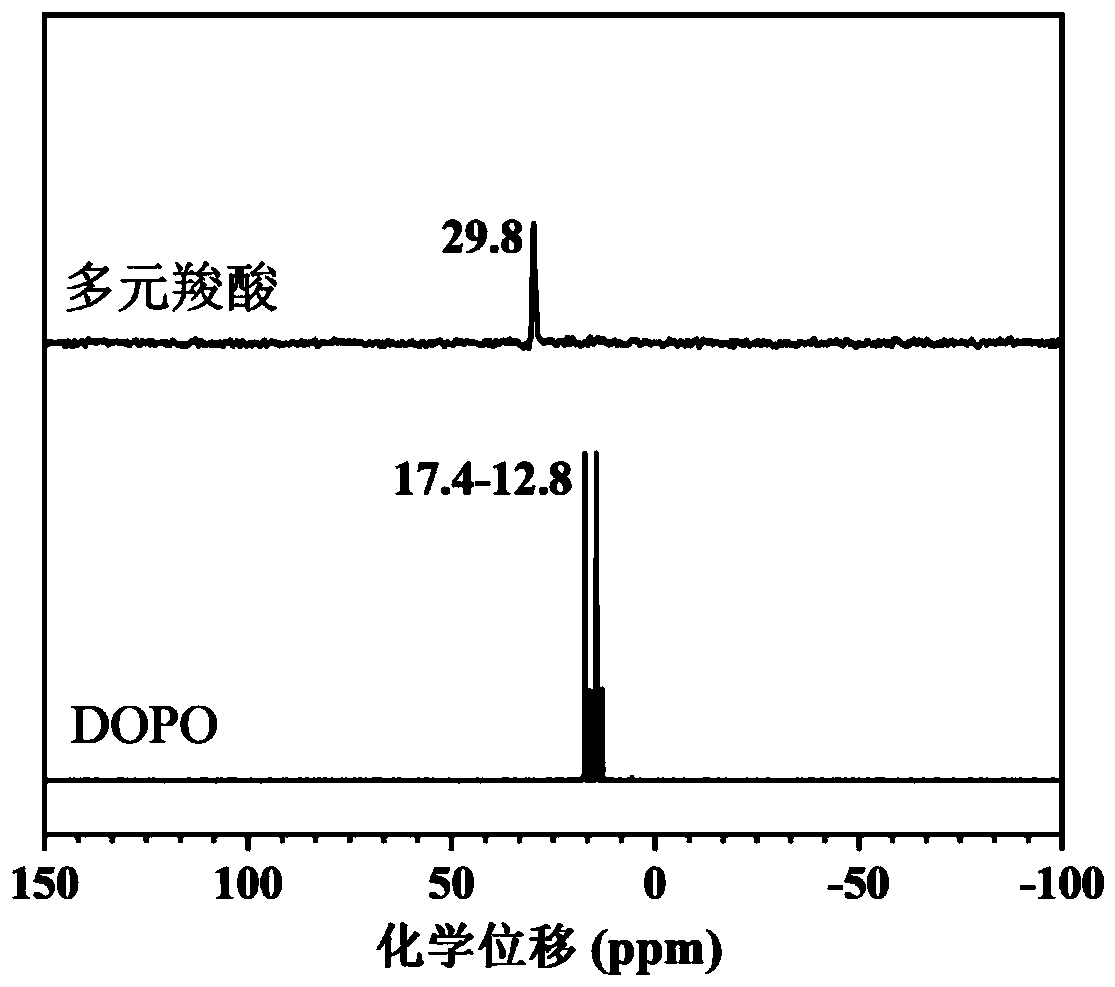

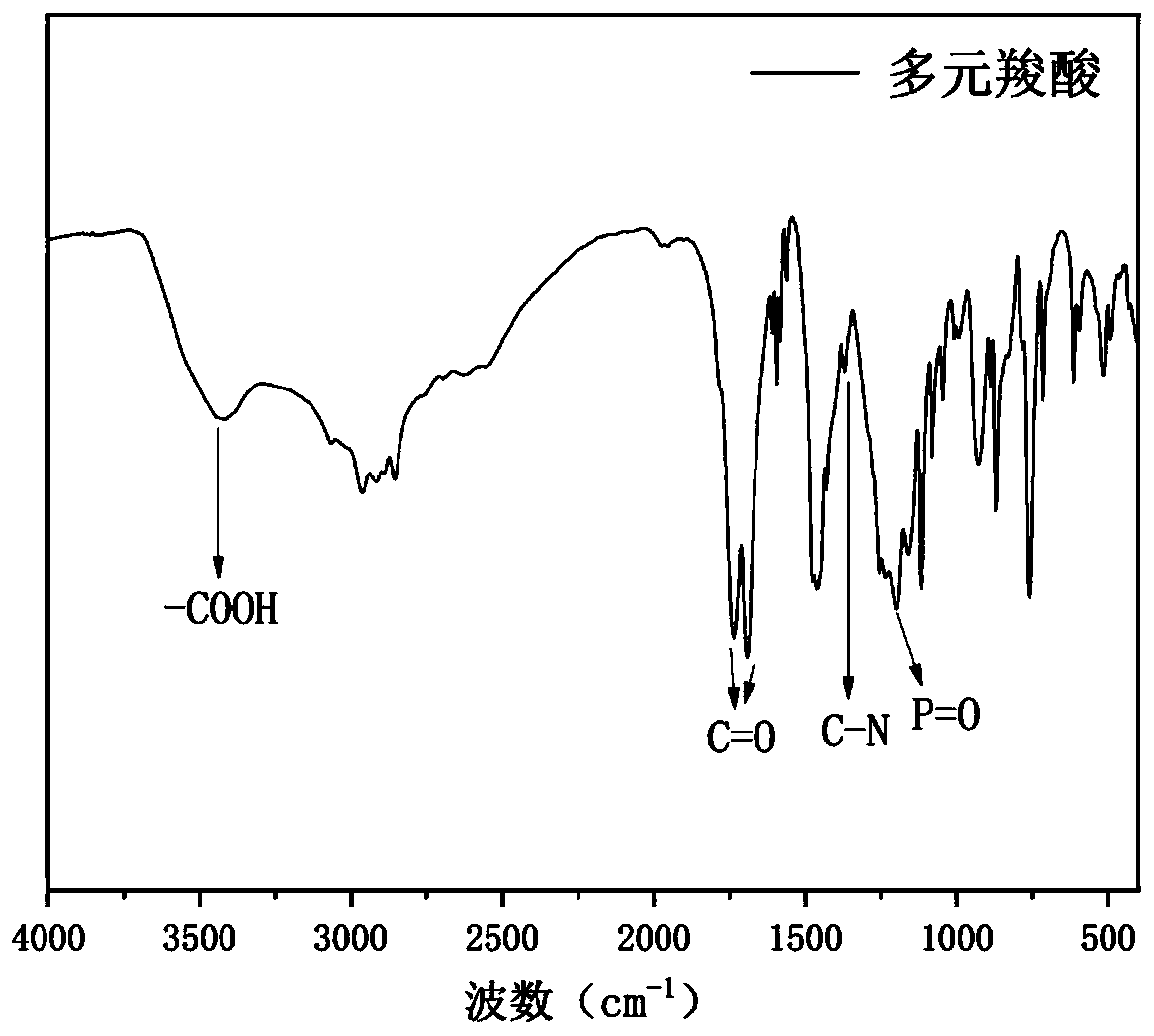

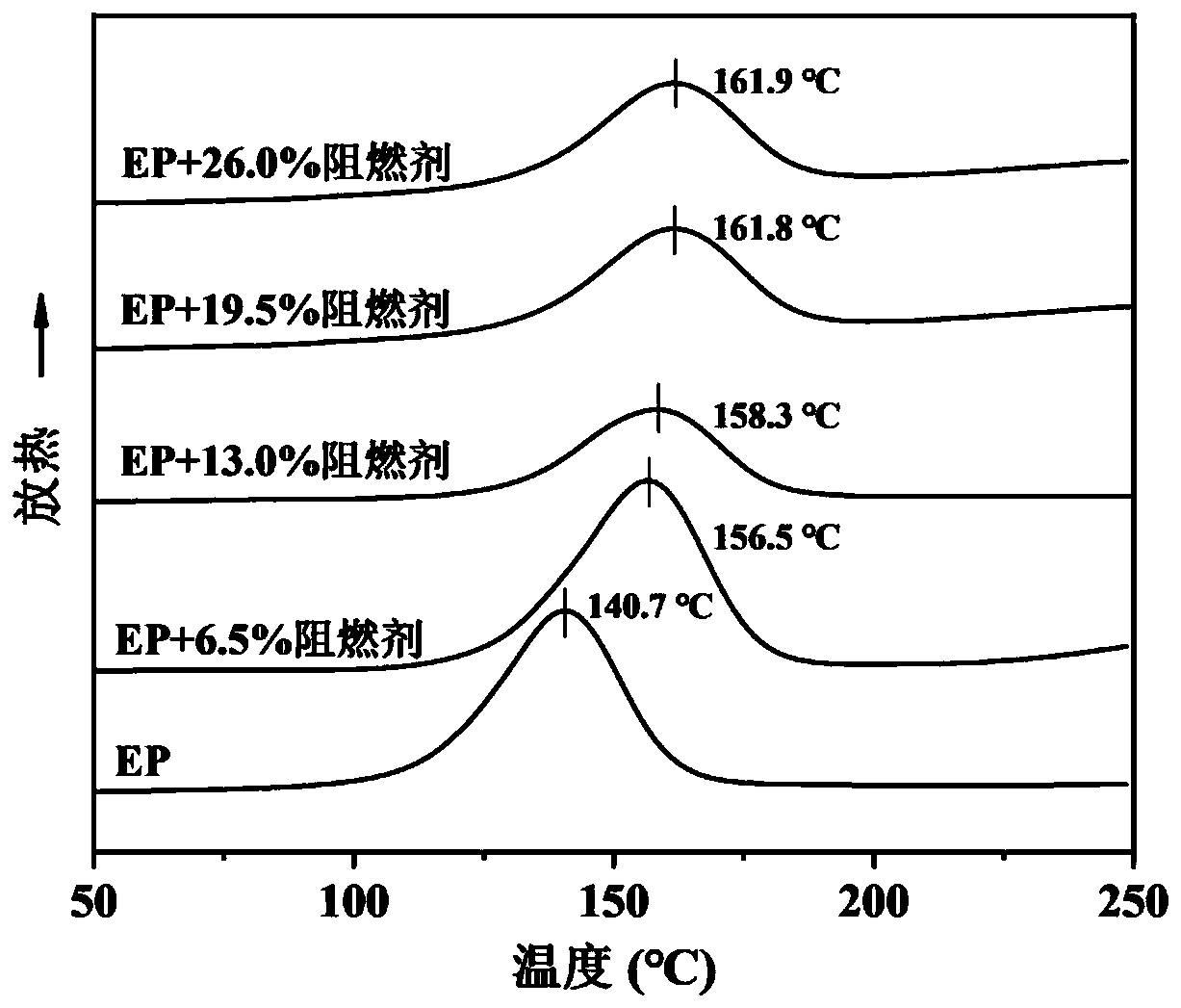

Preparation method of polycarboxylic acid and flame-retardant epoxy resin thereof

ActiveCN109988285AThe synthesis process is simpleMild reaction conditionsGroup 5/15 element organic compoundsHalogenMaleic anhydride

The invention discloses a preparation method of polycarboxylic acid and flame-retardant epoxy resin thereof. The preparation method comprises the following steps: (1) preparation of polycarboxylic acid: three steps of esterification, addition and purification are included; and (2) preparation of flame-retardant epoxy resin. The polycarboxylic acid of the invention is prepared from tris(2-hydroxyethyl) isocyanurate, maleic anhydride, 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide. The preparation method is simple and environment-friendly, and the production cost is low. The polycarboxylic acid has flame retardancy and reactivity at the same time, the flame retardancy of common epoxy resin can be remarkably improved, and good process performance and excellent physical and mechanical properties of the epoxy resin can be kept. The technical problems that the manufacturability and stability of an epoxy resin additive type flame retardant are poor, and a reaction type halogen flame retardant is not environmentally friendly at present are solved. The prepared flame-retardant epoxy resin can be widely applied to the fields of electronic appliances, chemical environmental protection, house construction, transportation, aerospace and the like.

Owner:WUHAN UNIV OF TECH

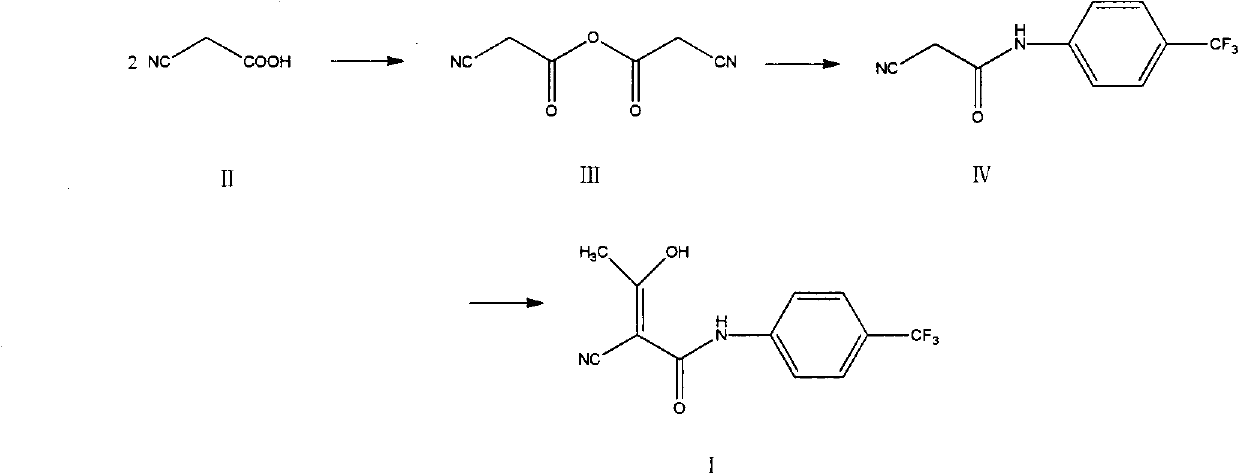

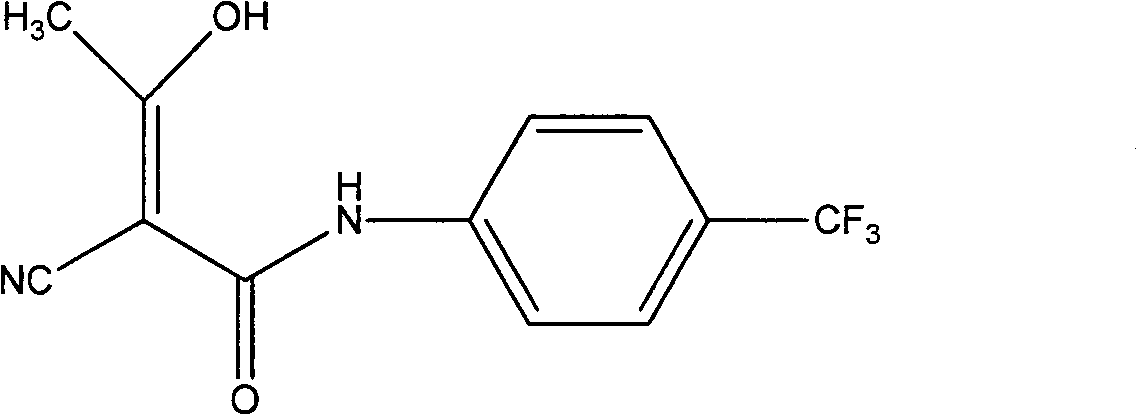

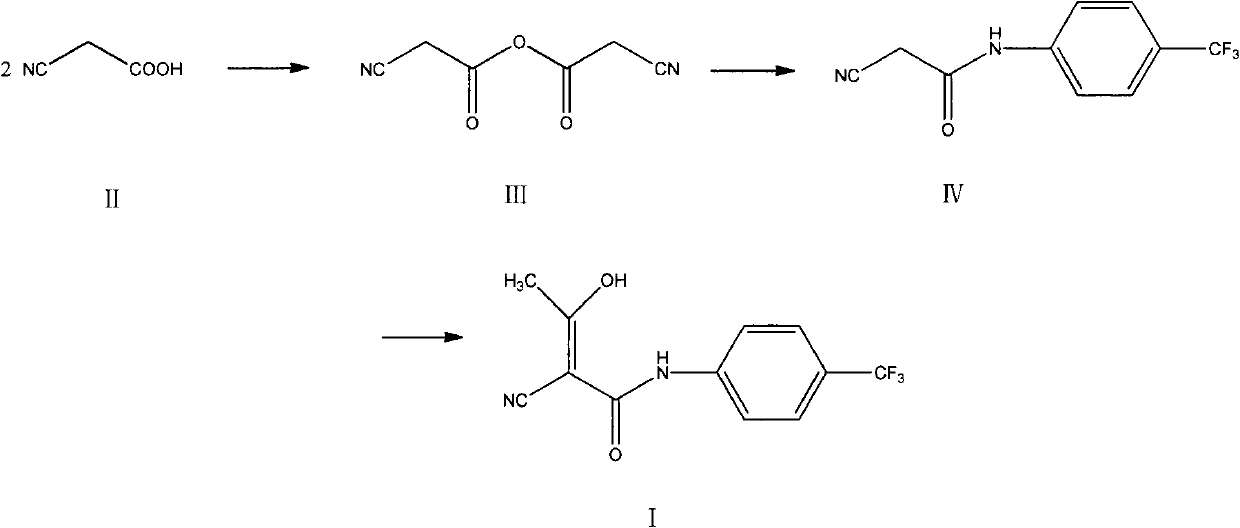

Preparation method of teriflunomide

InactiveCN102786437AImprove water stabilitySimple and fast operationCarboxylic acid nitrile preparationOrganic compound preparationAcetic anhydrideCyanoacetic acid

The invention relates to a preparation method of (Z)-2-cyano-3-hydroxy-N-(4-(trifluoromethyl)phenyl)-2-butenamide (I). The preparation method is characterized in that cyanoacetic acid (I) is dehydrated and condensed to obtain cyan acetic anhydride (III), the cyan acetic anhydride (III) reacts with trifluoromethyl phenyl under the action of catalyst to obtain 2-cyano-N-(4-trifluoromethyl-phenyl)-ethanamide (IV), and the 2-cyano-N-(4-trifluoromethyl-phenyl)-ethanamide (IV) reacts with the acetylchloride in the presence of sodium hydride to obtain teriflunomide (I).

Owner:CHINA PHARM UNIV

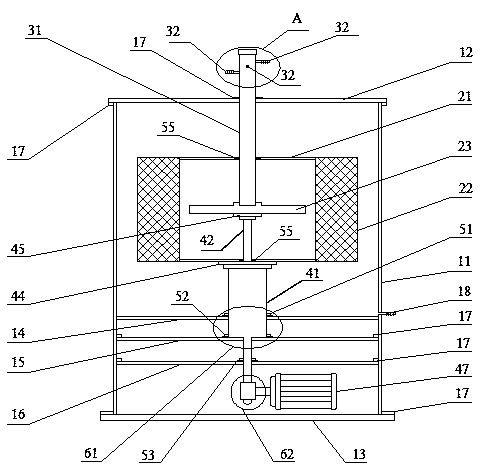

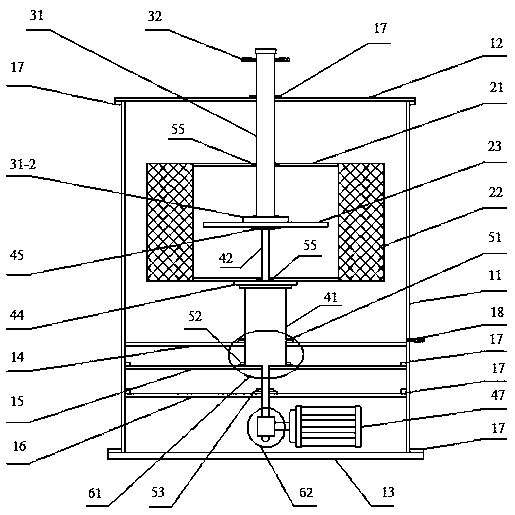

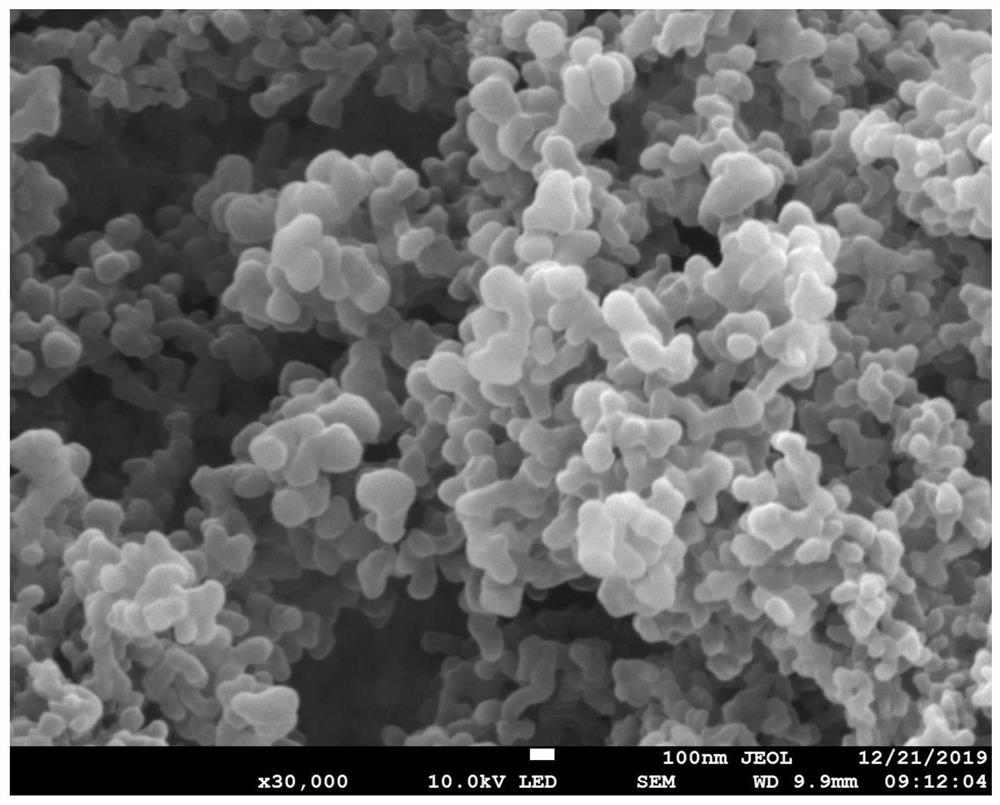

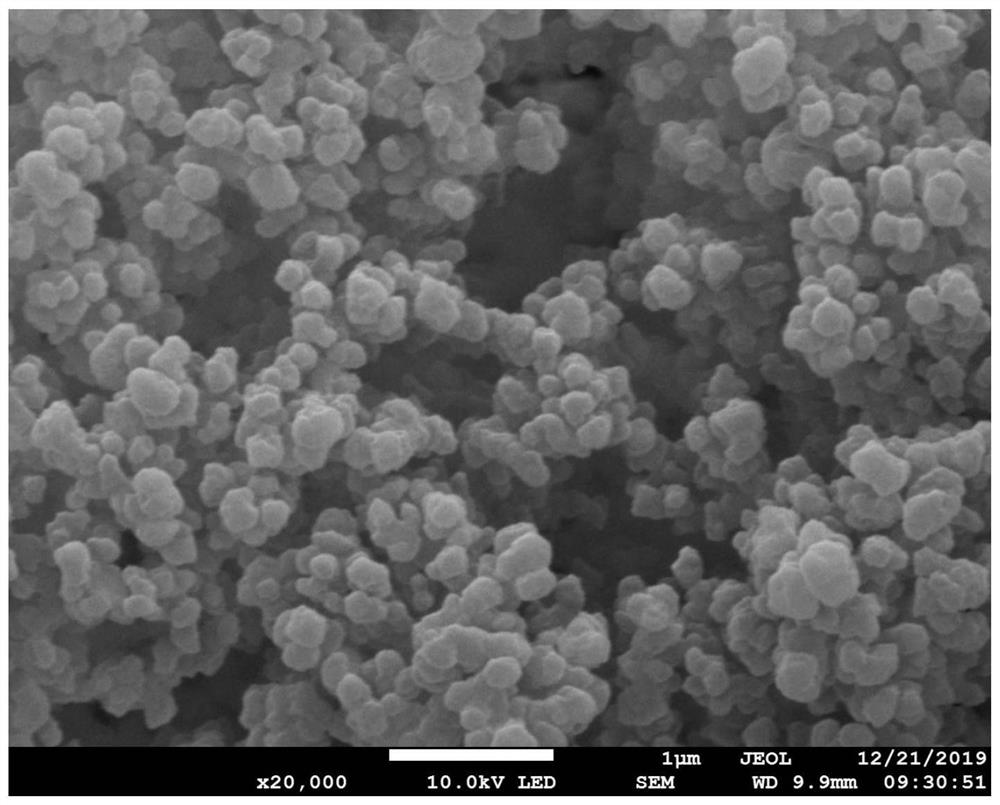

Method for preparing nano-silica

ActiveCN110885087AUniform and controllable particle sizeGood value for industrial productionSilicaNanotechnologyEngineeringSlurry

The invention discloses a method for preparing nano-silica. The method comprises the following steps: (1) preparing a solution A containing a silicon source and a solution B containing a precipitator;(2) adding the solution A and the solution B into a supergravity micro-reaction device, and performing a reaction to obtain a precursor slurry; (3) carrying out solvothermal treatment on the precursor slurry; and (4) carrying out solid-liquid separation on the product, and carrying out washing, drying and calcining treatment to obtain the nano-silica material. The method is completed in a supergravity micro-reaction device, the device comprises a micro-reaction disc and a packing layer, and the micro-reaction disc and the packing layer coaxially and reversely rotate, so that the mass transfereffect is greatly enhanced while raw materials are quickly and uniformly mixed, thereby the nucleation size of the product is reduced, the dispersity and uniformity of the nano-material are improved,and the energy consumption is reduced.

Owner:中垦农芯(佛山)智能科技有限公司

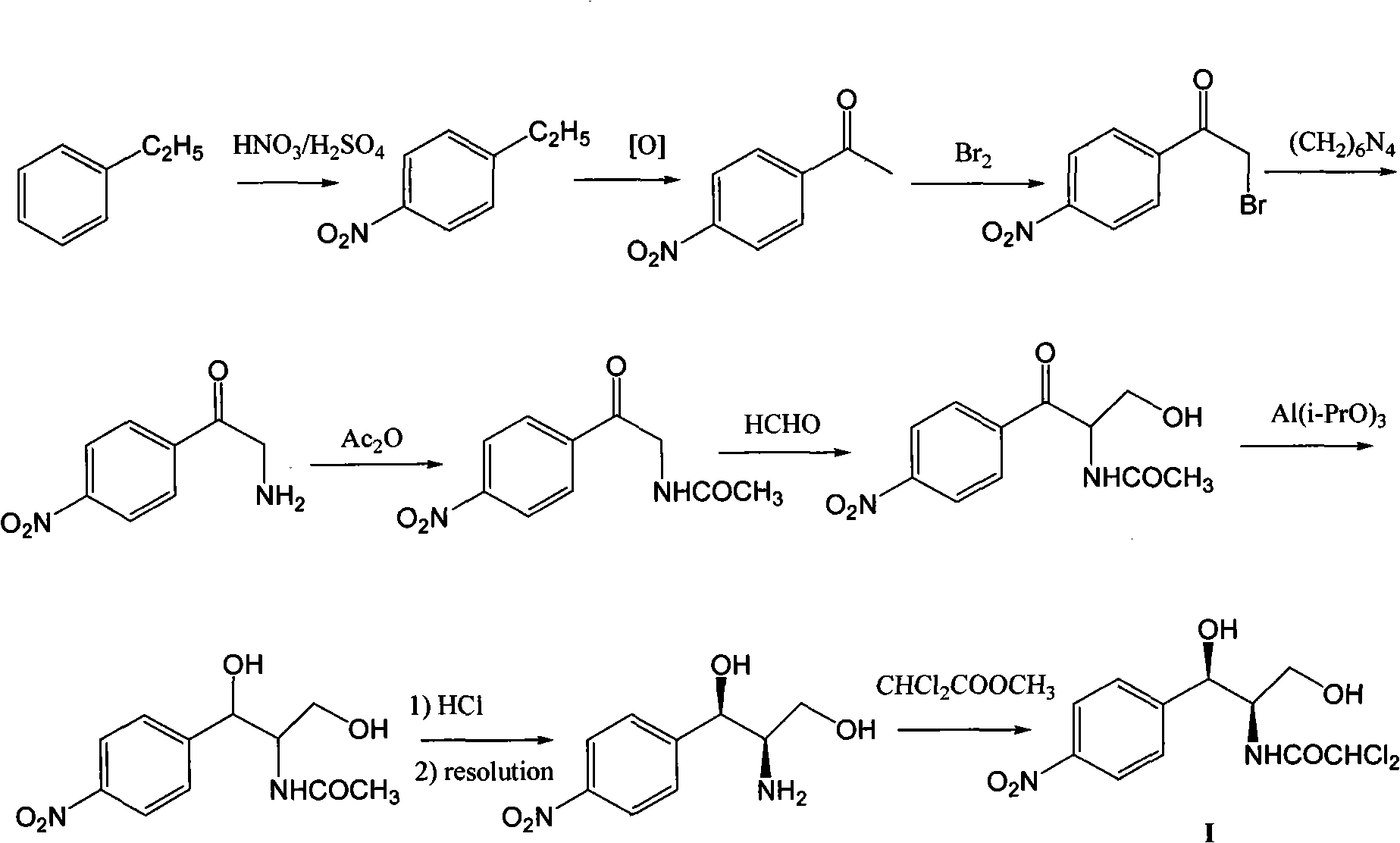

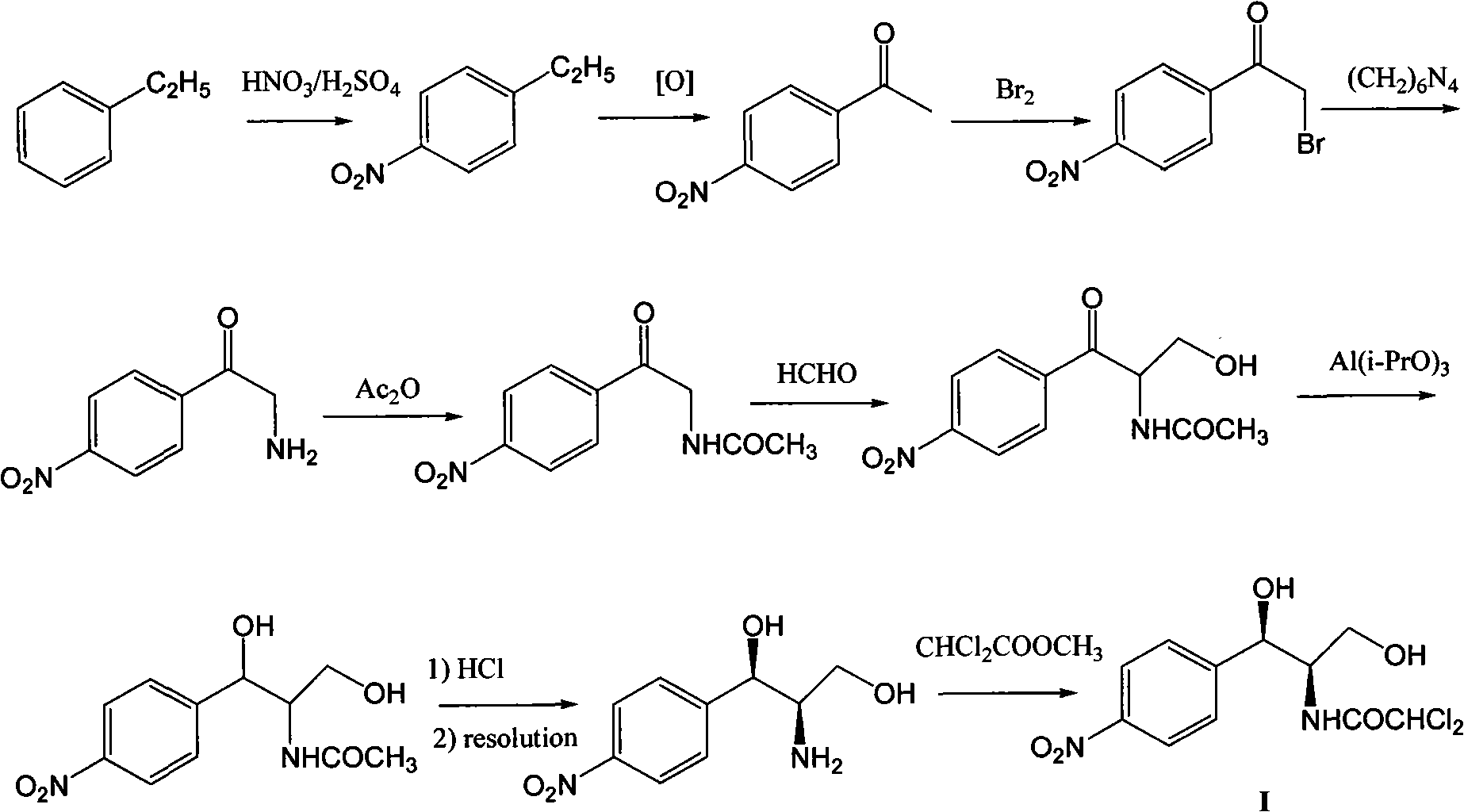

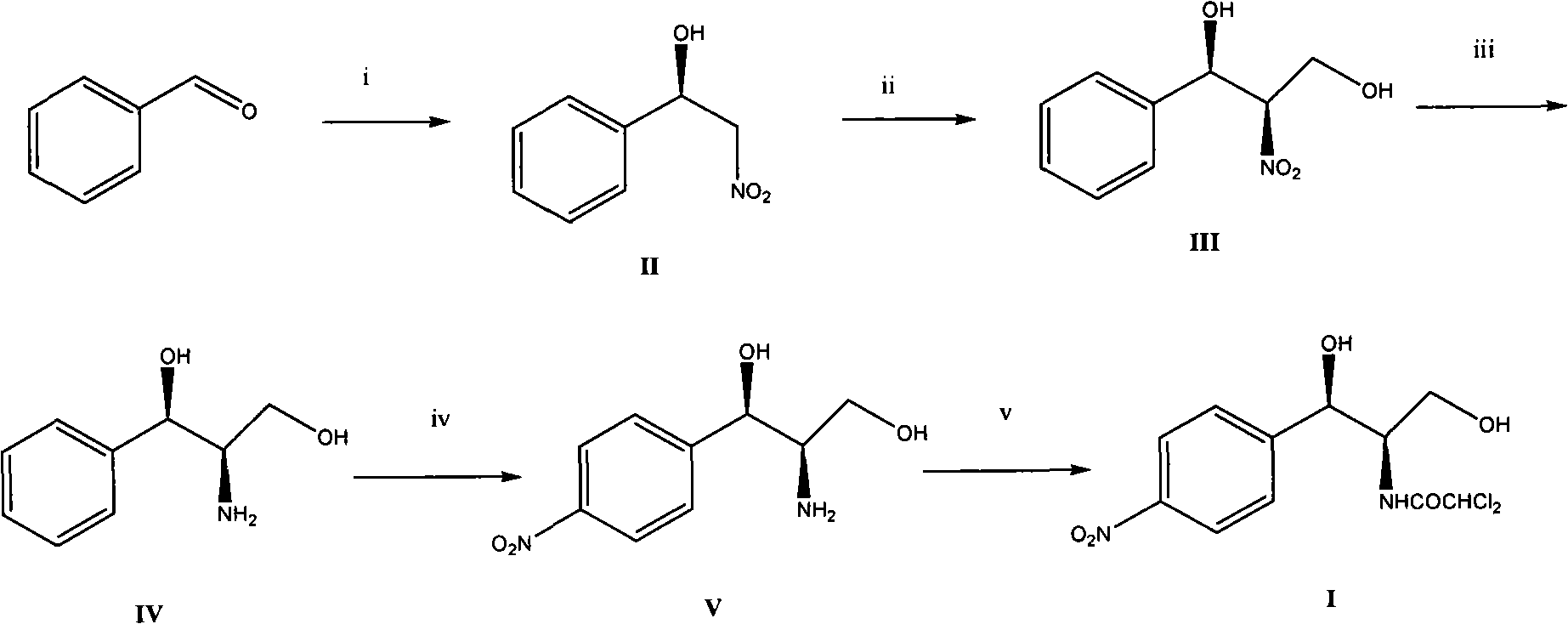

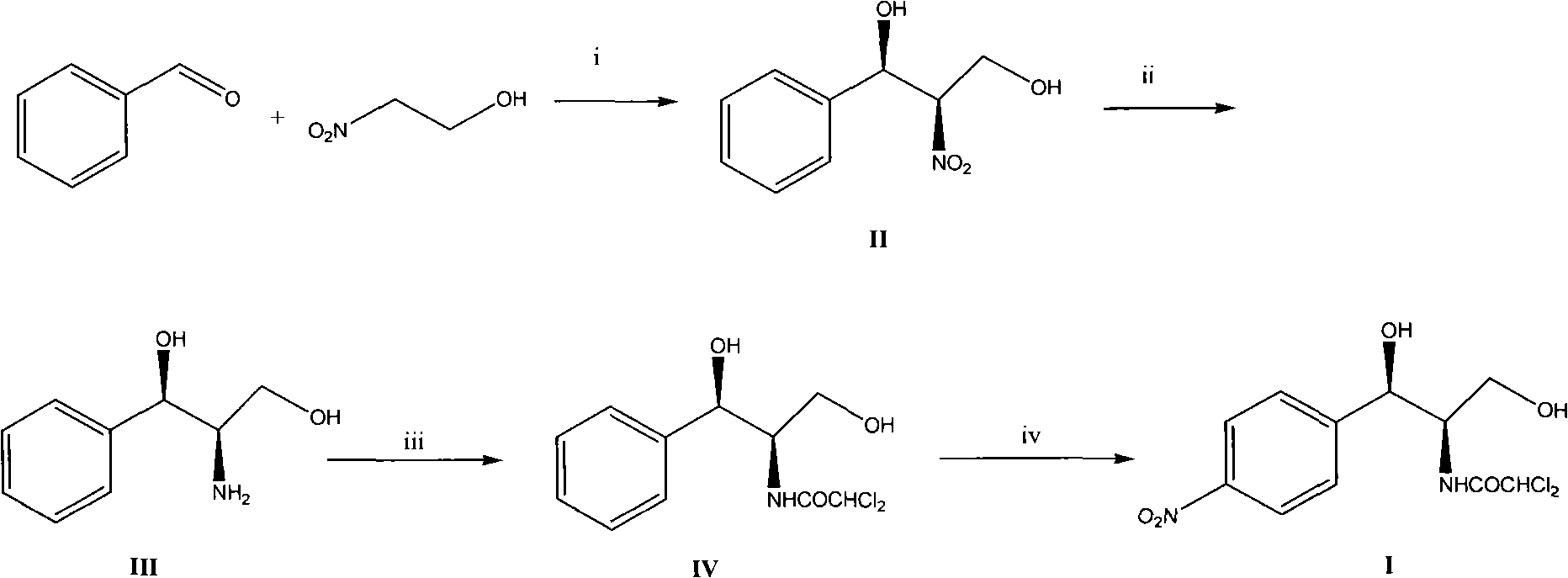

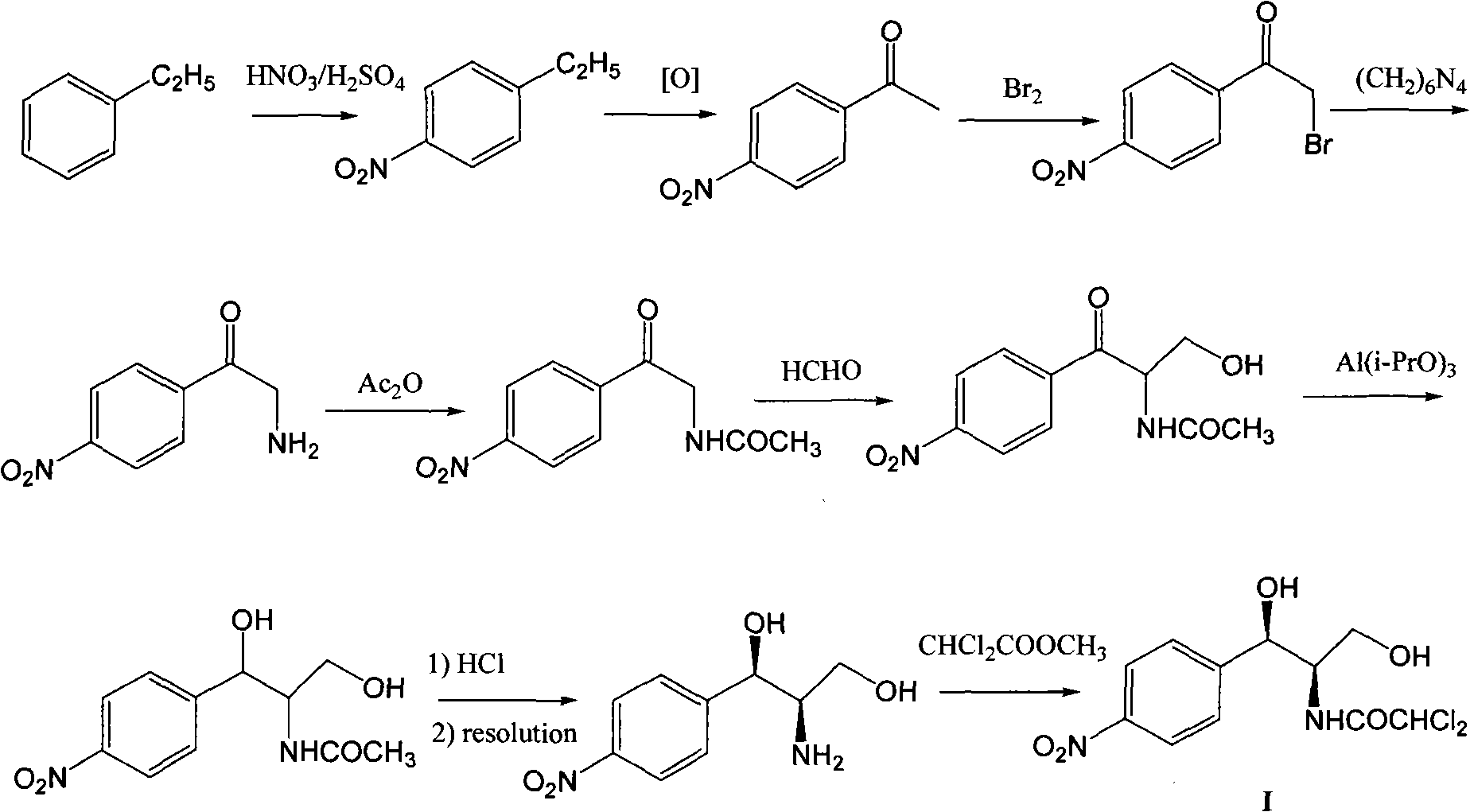

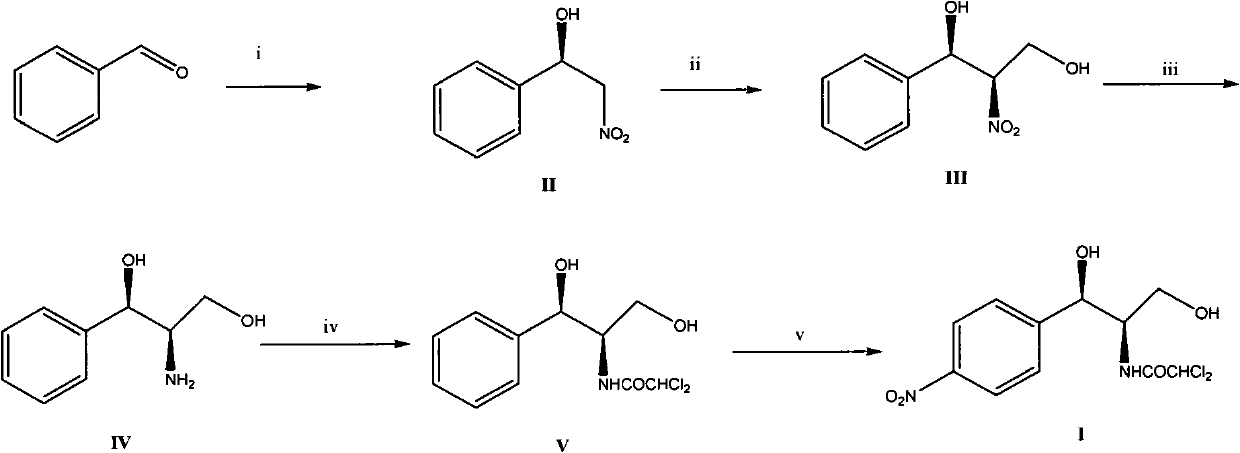

Method for preparing chloramphenicol

ActiveCN102399161ARaw materials are cheap and easy to getLow costOrganic compound preparationCarboxylic acid amides preparationBenzaldehydeNitration

The invention relates to a method for preparing a broad spectrum antibiotic of chloramphenicol. The method comprises the following steps of: synthesizing (R)-2-nitro-1-benzylcarbinol by using benzaldehyde and nitromethane as raw materials in the presence of a chiral catalyst; reacting with formaldehyde to obtain (1R,2R)-2-nitro-1-benzyl-1,3-propanediol, and performing hydrogenation reduction to obtain (1R,2R)-2-amino-1-benzyl-1,3-propanediol; and performing nitration and dichloro acetylization on the intermediate at low temperature to obtain the chloramphenicol. By the method, the common chiral resolution and aluminum isopropoxide reduction in the industry at present can be avoided, three wastes are reduced, the raw materials and reagents are cheap and readily available, the method comprises a few synthesizing steps, the yield is high, and the method is more suitable for industrial production.

Owner:WUHAN WUYAO SCI & TECH

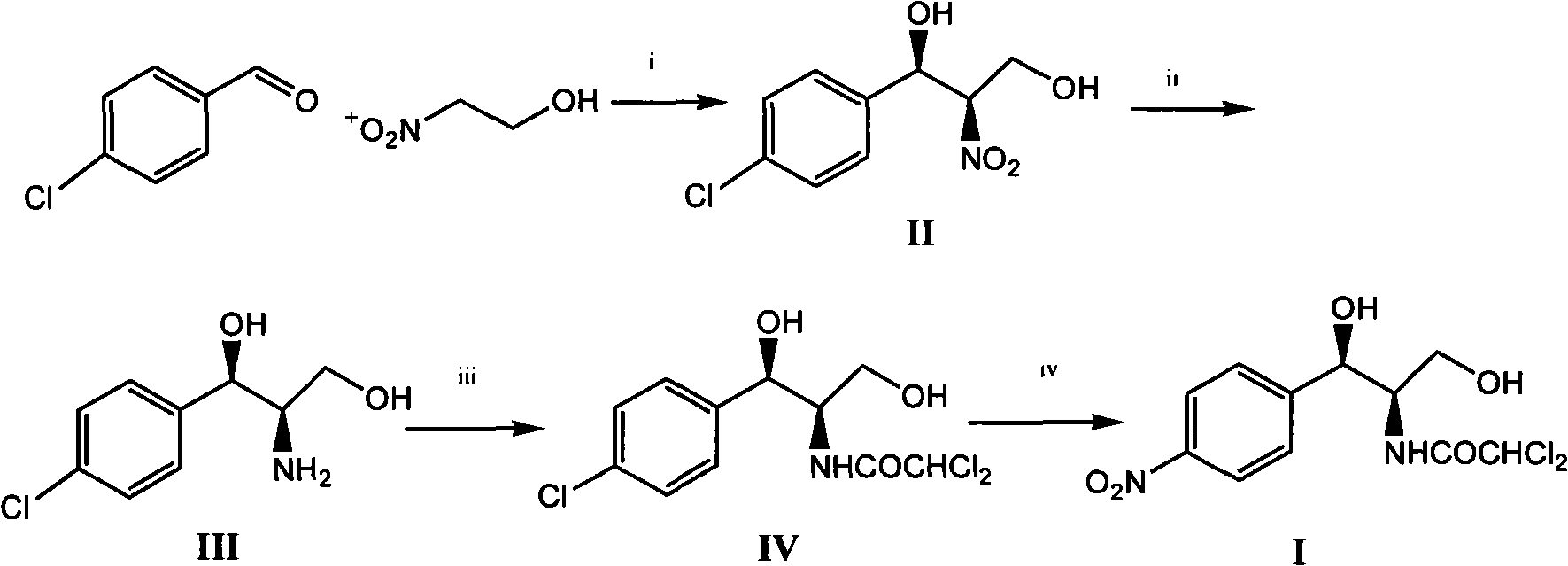

Method for preparing chloramphenicol from 4-chloro-benzaldehyde

ActiveCN102399163AHigh purityHigh yieldOrganic compound preparationCarboxylic acid amides preparationBenzaldehydeP-chlorobenzaldehyde

The invention relates to a method for preparing a broad spectrum antibiotic of chloramphenicol. The method comprises the following steps of: synthesizing (1R,2R)-2-nitro-1-(4-chlorophenyl)-1,3-propanediol by using 4-chlorobenzaldehyde and 2-nitroethylalcohol as raw materials in the presence of a chiral catalyst, and performing catalytic hydrogenation to obtain (1R,2R)-2-amino-1-(4-chlorophenyl)-1,3-propanediol; and performing nitro substitution and dichloro acetylization on the intermediate to obtain the chloramphenicol. By the method, the common chiral resolution and aluminum isopropoxide reduction in the industry at present can be avoided, three wastes are reduced, the raw materials and reagents are cheap and readily available, p-chlorobenzaldehyde is selected as a raw material, the method comprises a few synthesizing steps, the yield is high, and the method is suitable for industrial production.

Owner:GRAND PHARM (CHINA) CO LTD

Method for synthesizing chloramphenicol from 4-chloro-benzaldehyde

ActiveCN102399162AHigh purityHigh yieldOrganic compound preparationCarboxylic acid amides preparation4-chlorobenzaldehydeBenzaldehyde

The invention relates to a method for synthesizing a broad spectrum antibiotic, namely, chloramphenicol. The method comprises the following steps of: synthesizing (1R,2R)-2-nitro-1-(4-chlorophenyl)-1,3-propanediol by using 4-chlorobenzaldehyde and 2-nitroethylalcohol as raw materials in the presence of a chiral catalyst, and performing catalytic hydrogenation to obtain (1R,2R)-2-amino-1-(4-chlorophenyl)-1,3-propanediol; and performing dichloro acetylization and nitro substitution on the intermediate to obtain the chloramphenicol. By the method, the common chiral resolution and aluminum isopropoxide reduction in the industry at present can be avoided, three wastes are reduced, and the raw materials and reagents are cheap and readily available; 4-chlorobenzaldehyde is selected as a raw material, nitro substitution is adopted, and the generation of byproducts in nitration reaction is reduced; moreover, the method comprises a few synthesizing steps, the yield is high, and the method is more suitable for industrial production.

Owner:WUHAN WUYAO SCI & TECH

A kind of synthetic method of broad-spectrum antibiotic chloramphenicol

ActiveCN102285896ARaw materials are cheap and easy to getLow costOrganic compound preparationCarboxylic acid amides preparationBenzaldehydeAntibiotic Y

The invention relates to a method for synthesizing broad-spectrum antibiotic chloramphenicol. In the method, benzaldehyde and 2-nitroethanol are used as raw materials and are synthesized in the presence of a chiral catalyst to obtain (1R, 2R)-2-nitro-1-phenyl-1,3-propylene glycol; the (1R, 2R)-2-nitro-1-phenyl-1,3-propylene glycol is subjected to hydrogenation reduction to obtain (1R, 2R)-2-amino-1-phenyl-1,3-propylene glycol; and the (1R, 2R)-2-amino-1-phenyl-1,3-propylene glycol is dichloroacetylated and nitrified to obtain the chloramphenicol. By using the method provided by the invention, chiral separation and aluminum isopropoxide reduction which are generally used in industry at present can be avoided; three wastes (waste water, waste gas and industrial residues) are reduced; and the method has the advantages of low-cost and readily available raw materials and reagents, less synthesis steps and high yield and is more suitable for industrial production.

Owner:WUHAN WUYAO PHARMA

Production method of creamy fermented bean curd

InactiveCN106417665ALow viscosityIncrease the fragranceCheese manufactureFood sciencePectinaseHydrolysate

The invention provides a production method of creamy fermented bean curd, comprising: mixing well soybean flour and water to obtain fermentation material; adding pectinase and cellulase to the fermentation material, enzymatically hydrolyzing at 40-55 DEG C for 2-4 h, and sterilizing to obtain primary hydrolysate; adding Bacillus subtilis and Micrococcus luteus to the primary hydrolysate, enzymatically hydrolyzing at 35-45 DEG C for 8-18 h, and sterilizing to obtain secondary hydrolysate; adding rice saccharified liquid, soy sauce aroma enhancing yeast and lactic acid bacteria to the secondary hydrolysate, performing aroma-enhancing enzymatic hydrolysis at 40-55 DEG C for 20-30 h, and sterilizing to obtain mixed fermentation broth; flavoring and thickening the mixed fermentation broth to obtain the creamy fermented bean curd. The creamy fermented bean curd has little edible salt and good flavor, is significantly lower in salinity than common fermented bean curd, is better in health and safety, takes short time to produce, and has higher industrial production value.

Owner:安顺市平坝区万佳农产品开发有限公司

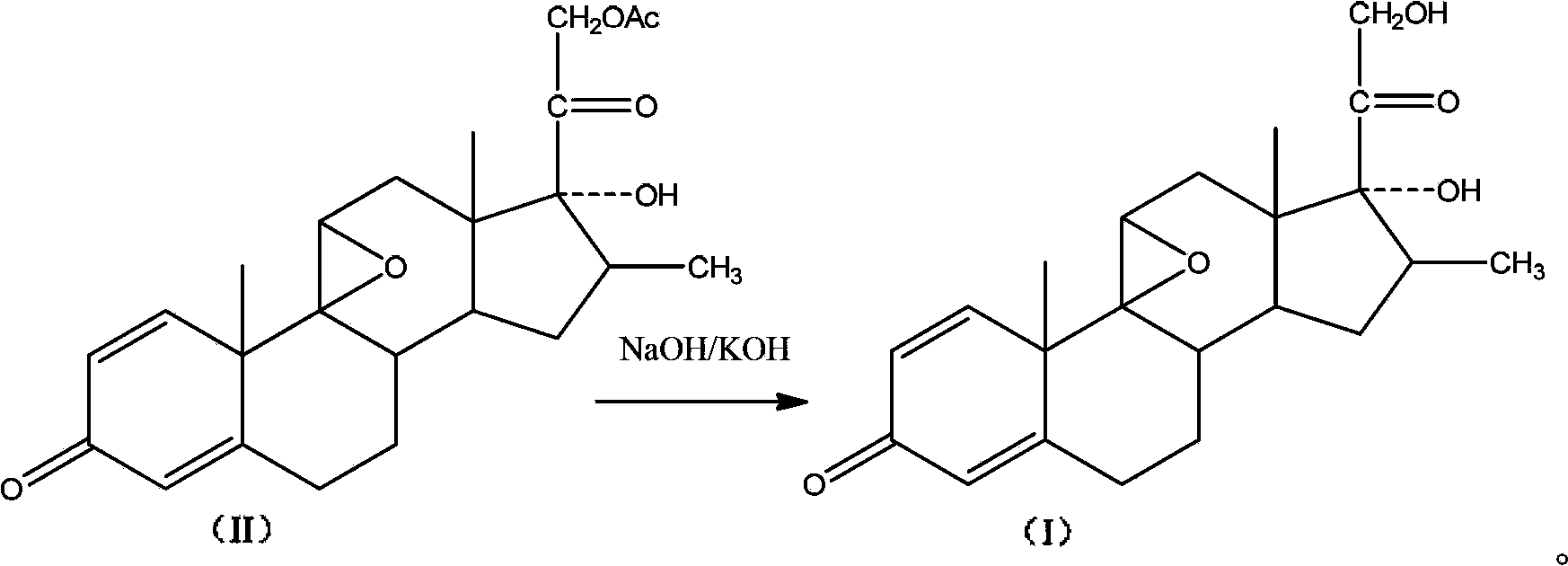

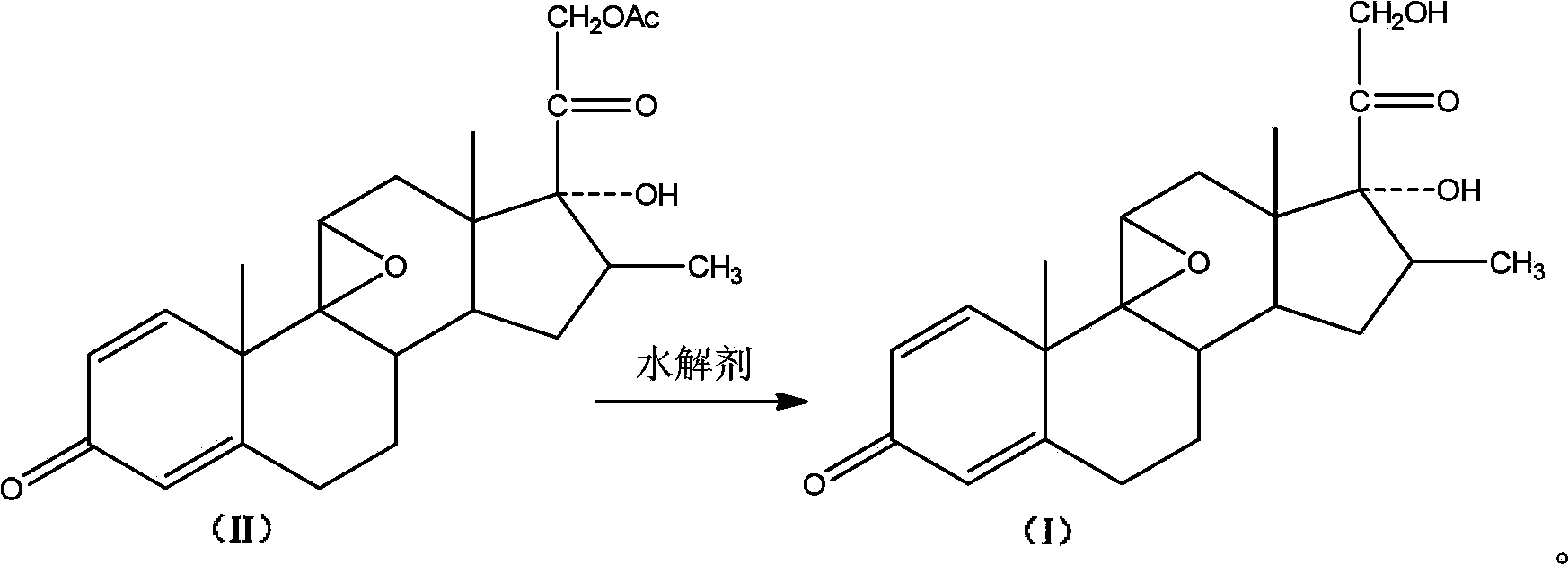

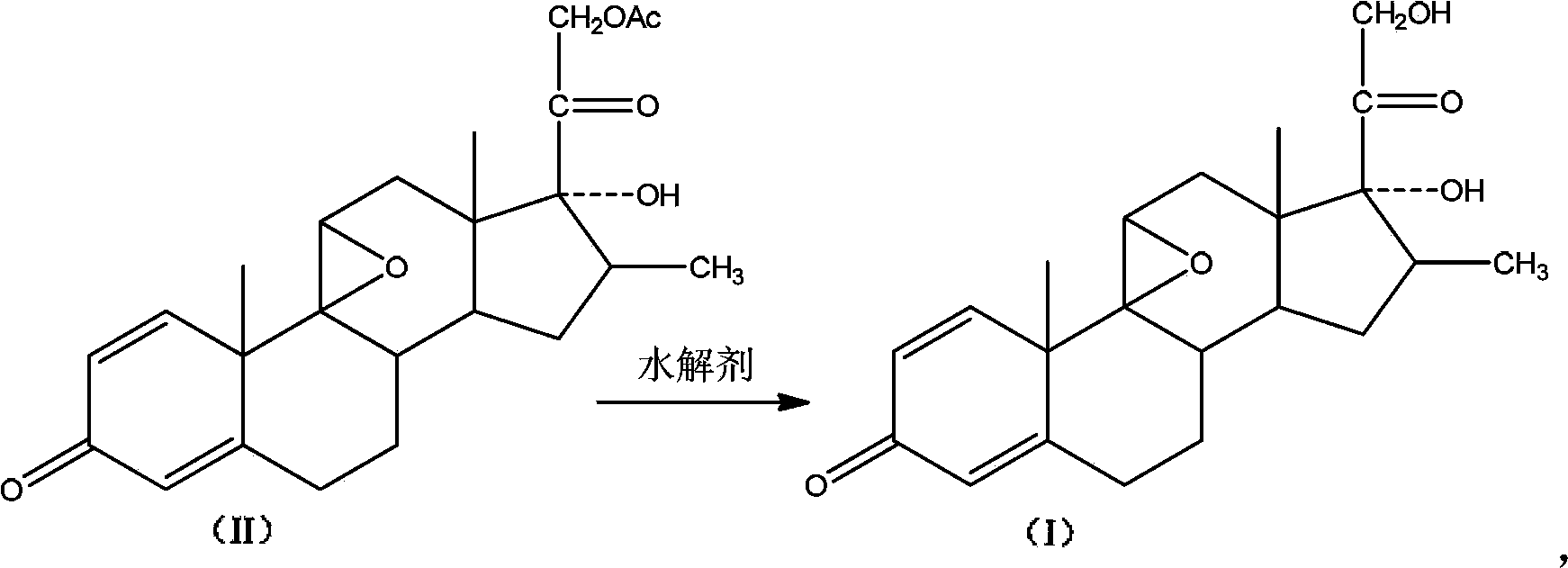

Preparation method of betamethasone intermediate

The invention discloses a preparation method of betamethasone intermediate hydrolysate (I), which employs a betamethasone substitute (II) as substrate, and employs a hydrolytic agent with reductibility to hydrolyze, and a compound in formula (I) is obtained. The reaction formula is shown in the figure. The invention employs the hydrolytic agent with reductibility to prepare the hydrolysate (I), and has the characteristics of high yield and good quality with good industrial production value.

Owner:SHANGHAI NEW HUALIAN PHARMA

Carboxyl-containing vinyl chloride copolymer resin and preparation method thereof

The present invention relates to a carboxyl-containing vinyl chloride copolymer resin. This carboxyl-containing vinyl chloride copolymer resin has a chemical structure represented by formula (1): avinyl chloride based structural unit (a) and a structural unit (b) based on a monomer represented by a formula (2) are included, CR1R2=CR3R4COOH (2) (in formula (2), R1 is selected from hydrogen, methyl,benzene ring, R2 is selected from hydrogen, methyl, a linear or branched alkyl group having 1-15 carbon atoms, R3 is selected from hydrogen and methyl, and R4 is selected from linear or branched alkyl or alkylene with the carbon number of 0-15. The content of the structural unit (b) is 1-20% by mass relative to the total mass of the carboxyl-containing vinyl chloride copolymer resin.

Owner:BEIJING UNIV OF CHEM TECH

ABS chromium-free coarsening solution, and preparation method and application thereof

PendingCN110172684AImprove stabilityGood coarsening effectLiquid/solution decomposition chemical coatingSuperimposed coating processChromium freeElectrolysis

The invention provides an ABS chromium-free coarsening solution. The coarsening solution is an aqueous solution containing manganese sulfate, sulfuric acid, phosphoric acid and methanesulfonic acid. The invention further provides a coarsening method of the chromium-free coarsening solution for ABS plastic. The prepared chromium-free coarsening solution is electrolyzed by an electrolysis device, the ABS plastic is placed in the coarsening solution for chemical coarsening, and the chromium-free coarsening solution needs to be connected with evaporation equipment so as to maintain the specific gravity of the solution. According to the coarsening solution, the environmental pollution caused by conventional chromium acid coarsening and the use of explosive raw materials such as potassium permanganate are avoided, the coarsening method improves the stability of coarsening liquid and coarsening capability, and the ABS chromium-free coarsening solution has good coarsening effect and industrialapplication value.

Owner:南通柏源汽车零部件有限公司

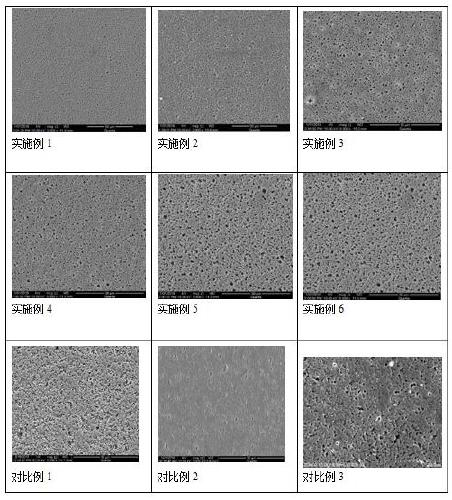

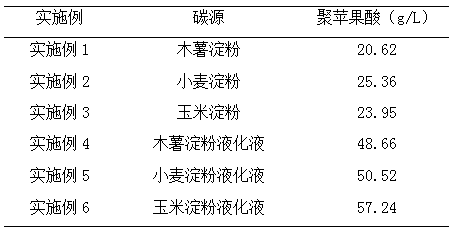

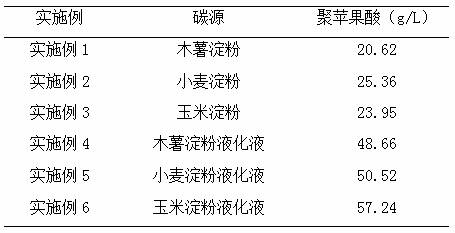

Aureobasidium pullulans strain capable of producing poly-beta-L-malic acid by utilizing starch and application thereof

The invention discloses an Aureobasidium pullulans strain capable of producing poly-beta-L-malic acid by utilizing starch and application thereof. The Aureobasidium pullulans strain is classified andnamed Aureobasidium pullulans GXL-1 under the preservation number of CCTCC NO: M 2018519 at China Center for Type Culture Collection (address: Wuhan University, Wuhan, China) since August 1, 2018. TheAureobasidium pullulans GXL-1 disclosed by the invention can directly use raw starch or a liquefied starch solution as a carbon source to produce poly-beta-L-malic acid at a mass concentration of 57g / L by carrying out batch fermentation at 30 DEG C without addition of a fermentation accelerator and growth factors; and moreover, no melanin is produced during the fermentation process. The Aureobasidium pullulans GXL-1 has the advantages of being low in fermentation cost, easy to realize product purification, and simple in process; and thus, the Aureobasidium pullulans GXL-1 has very great production potentials.

Owner:GUANGXI UNIV

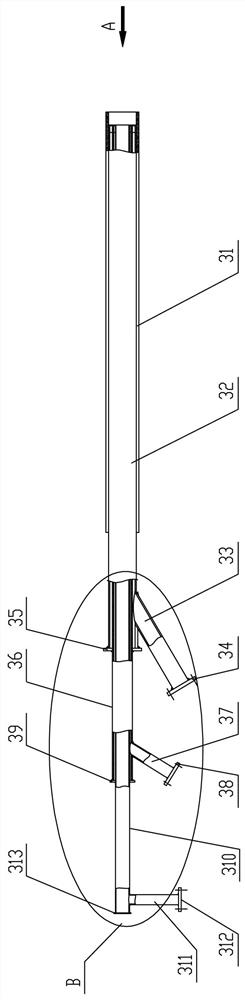

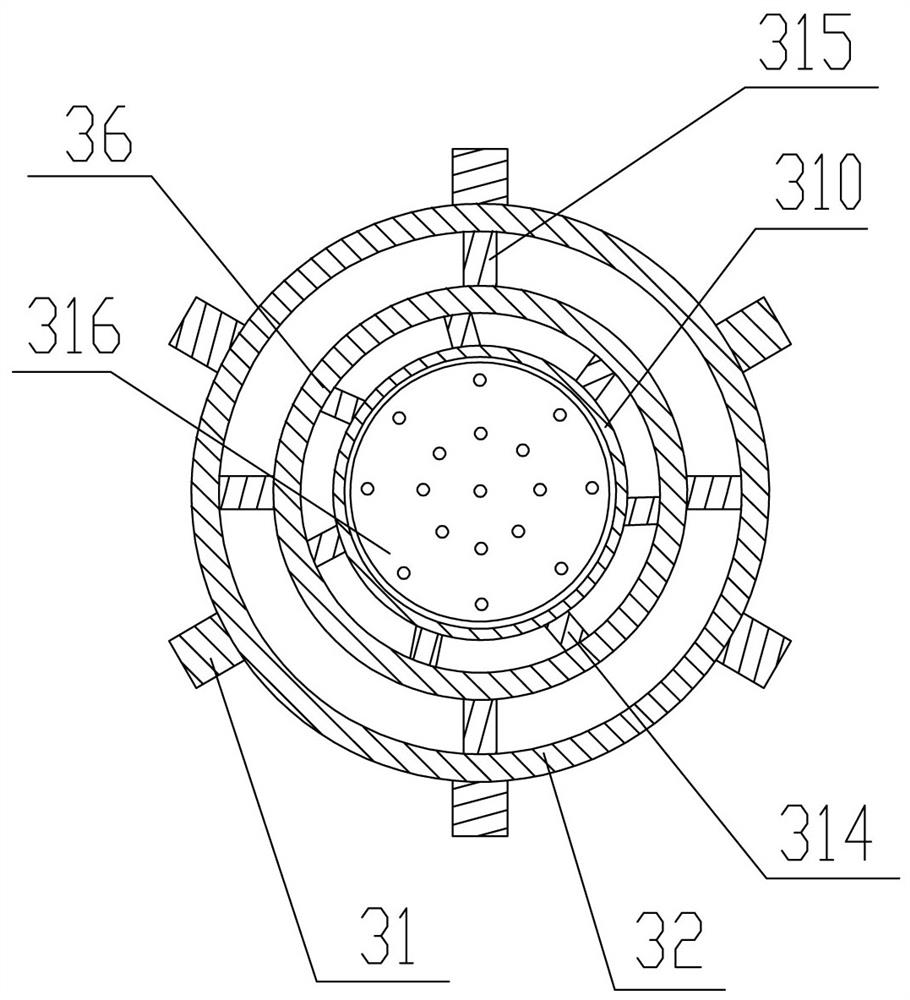

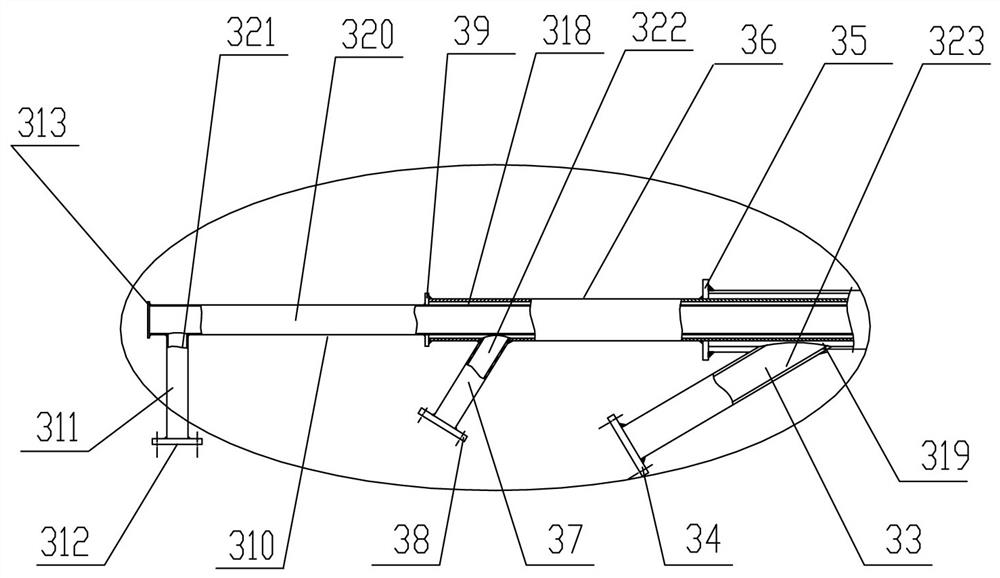

Three-channel pulverized coal burner and rotary kiln with same

PendingCN112484025ASimple structureEasy to installRotary drum furnacesPulverulent fuel combustion burnersThermodynamicsCombustor

The invention relates to a three-channel pulverized coal burner. The three-channel pulverized coal burner comprises an outer-layer pipeline, a middle-layer pipeline, an inner-layer pipeline, an inner-layer pipeline feeding branch pipe, a middle-layer pipeline feeding branch pipe, an outer-layer pipeline feeding branch pipe, a connecting flange I, a connecting flange II, a sealing flange, a controlbutterfly valve I, a control butterfly valve II, a control butterfly valve III, rotational flow pieces and a pore plate. Three sleeves are sequentially connected in a sleeved mode from inside to outside, reinforcing ribs are arranged on the outer side of the outer-layer pipeline, supporting pieces are arranged between the outer-layer pipeline at the front end of the three-channel pulverized coalburner and the middle-layer pipeline, the rotational flow pieces are arranged between the middle-layer pipeline and the inner-layer pipeline, and the pore plate is arranged at the front end of an inner-layer pulverized coal channel. The three-channel pulverized coal burner has the advantages that the shapes and the lengths of flames in the three sleeves can be adjusted by adjusting the opening degrees of the inner-layer control butterfly valve, the middle-layer control butterfly valve and the outer-layer control butterfly valve, the combustion speed of pulverized coal can be controlled to be moderate without adding external combustion-supporting air, and then the temperature distribution in a rotary kiln is uniform.

Owner:ANSTEEL GRP MINING CO LTD

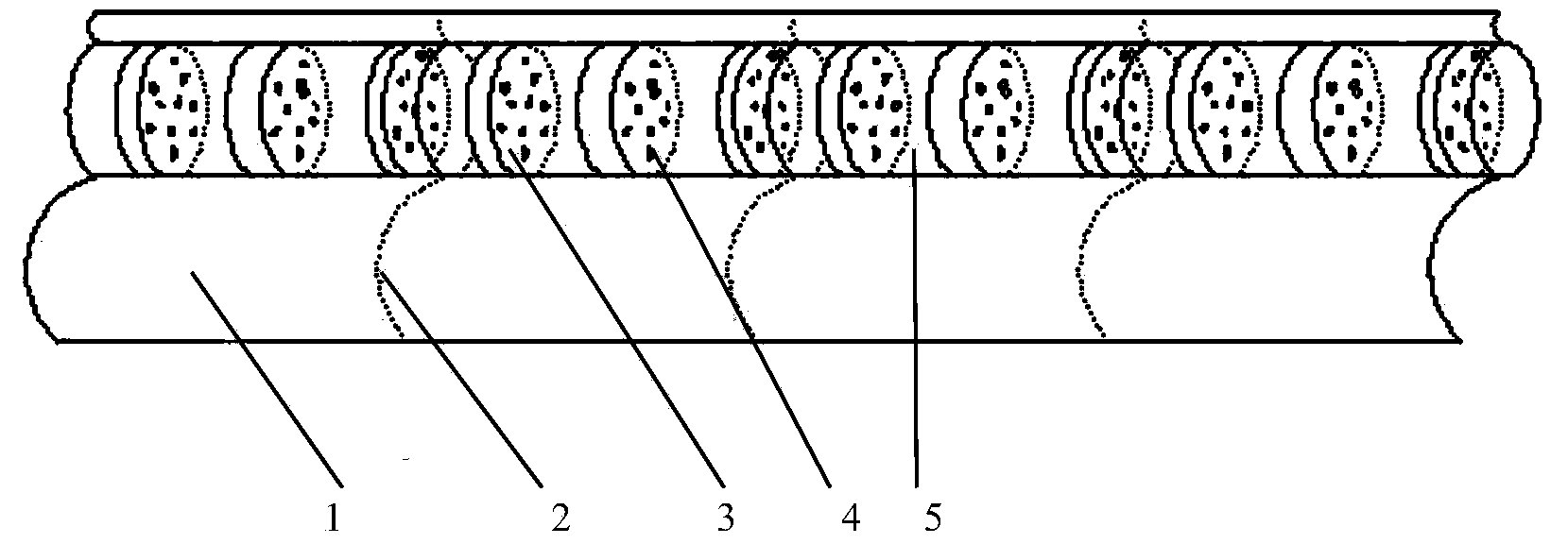

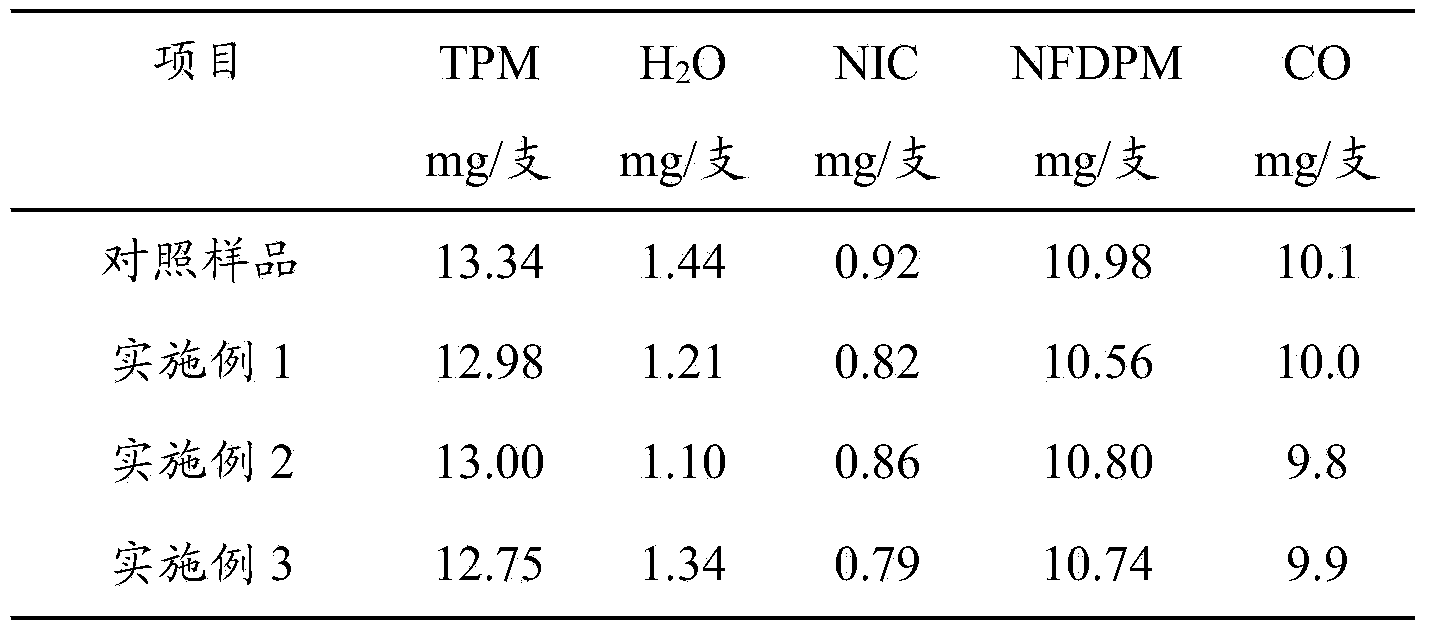

Air filter stick provided with resistance-increasing fixed pieces

The invention relates to an air filter stick provided with resistance-increasing fixed pieces. Multiple resistance-increasing fixed pieces are arranged in the air filter stick and parallelly and orderly arranged in the air filter stick. An air channel is arranged in the axial direction. The resistance-increasing fixed pieces are rolled to be cylindrical by using forming paper, and a cavity is formed between every two adjacent resistance-increasing fixed pieces. By adopting unique micropores, the smoke flowing speed is improved, a smoke flowing state is changed, and then a part of tar and other harmful substance settles and is absorbed.

Owner:GUANGDONG GOLDEN LEAF TECH DEV

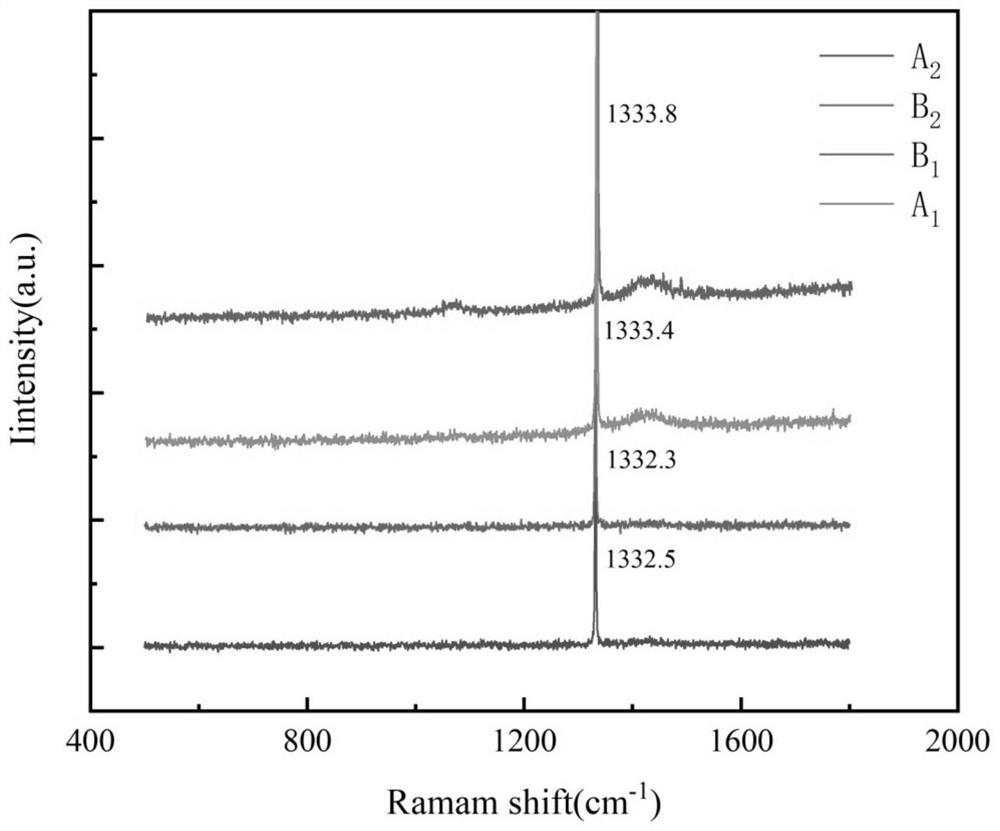

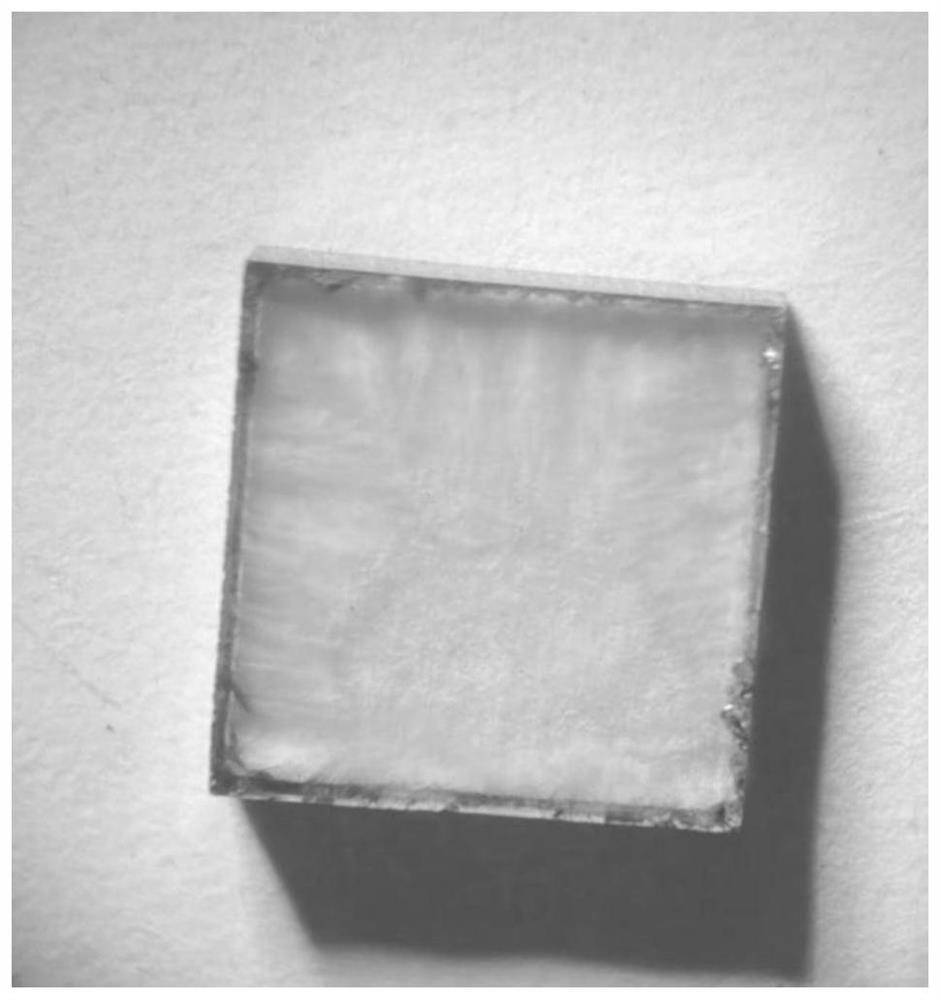

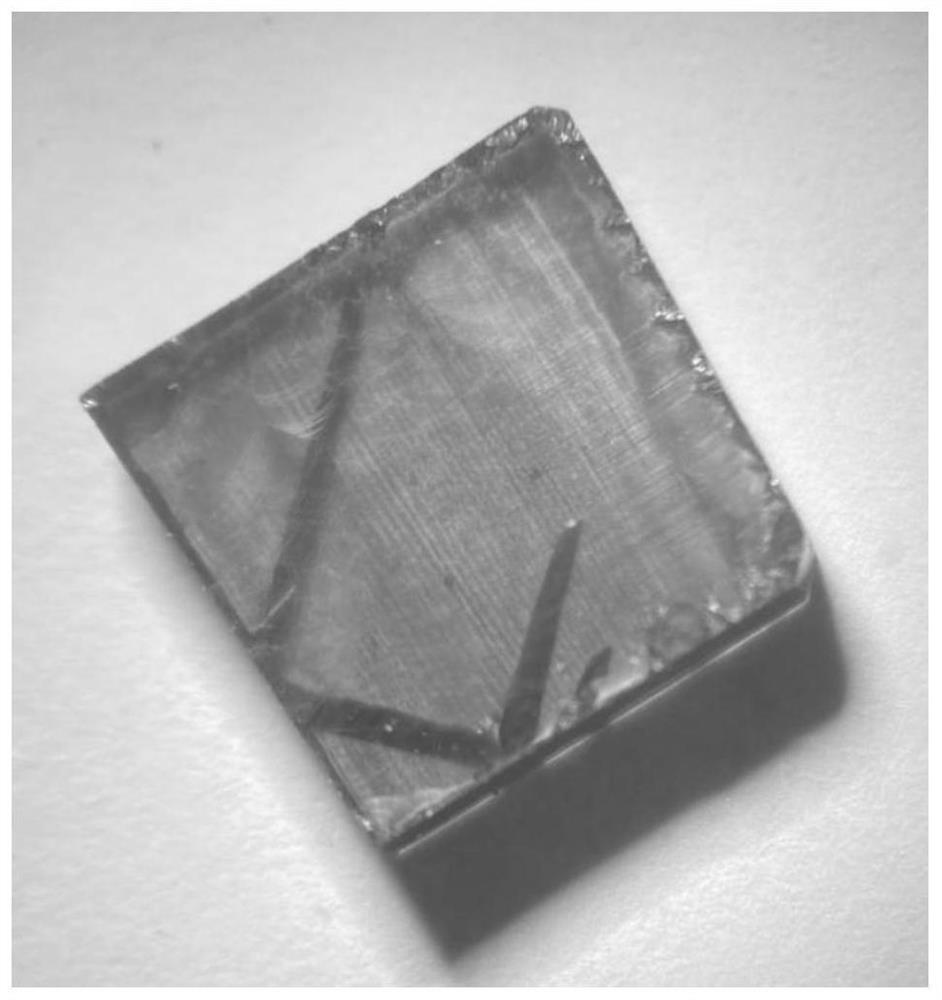

A treatment method for reducing the internal stress of single crystal diamond

ActiveCN113005517BReduce internal stressGuarantee product qualityPolycrystalline material growthAfter-treatment detailsCondensed matter physicsSeed crystal

The present application relates to the technical field of single crystal diamond preparation, and specifically discloses a treatment method for reducing the internal stress of single crystal diamond. Including the following steps: preparation of diamond seed crystal; growth of single crystal diamond - high temperature annealing treatment: diamond seed crystal is grown and high temperature annealing treatment, high temperature annealing is performed once after each growth, growth and high temperature annealing treatment are alternately performed, and the number of high temperature annealing is performed. 2 to 5 times until the single crystal diamond grows to 5.0-5.5mm; the high-temperature annealing treatment conditions for the single-crystal diamond: the high-temperature annealing temperature is 1000-2000°C, and the time is 30-90min. The method of the present application is simple to operate, easy to implement, simplifies the process flow, saves time and cost, and the single crystal diamond prepared by the present application has the advantages of low internal stress, high surface and internal quality, less cracks and high yield.

Owner:LANGFANG SUPOWER DIAMOND TECH

Method for synthesizing chloramphenicol from 4-chloro-benzaldehyde

ActiveCN102399162BHigh purityHigh yieldOrganic compound preparationCarboxylic acid amides preparation4-chlorobenzaldehydeBenzaldehyde

Owner:WUHAN WUYAO SCI & TECH

Method for preparing chloramphenicol from nitromethane

ActiveCN102399165BRaw materials are cheap and easy to getAvoid splittingOrganic compound preparationCarboxylic acid amides preparationP-chlorobenzaldehydeNitromethane

The invention relates to a method for preparing a broad spectrum antibiotic of chloramphenicol. The method comprises the following steps of: synthesizing (R)-2-nitro-1-(4-chlorophenyl)ethanol by using p-chlorobenzaldehyde and nitromethane as raw materials in the presence of a chiral catalyst; reacting with formaldehyde to obtain (1R,2R)-2-nitro-1-(4-chlorophenyl)-1,3-propanediol, and performing catalytic hydrogenation to obtain (1R,2R)-2-amino-1-(4-chlorophenyl)-1,3-propanediol; and performing dichloro acetylization and nitro substitution on the intermediate to obtain the chloramphenicol. By the method, the common chiral resolution and aluminum isopropoxide reduction in the industry at present can be avoided, three wastes are reduced, the raw materials and reagents are cheap and readily available, the method comprises a few synthesizing steps, the yield is high, and the method is more suitable for industrial production.

Owner:WUHAN WUYAO SCI & TECH

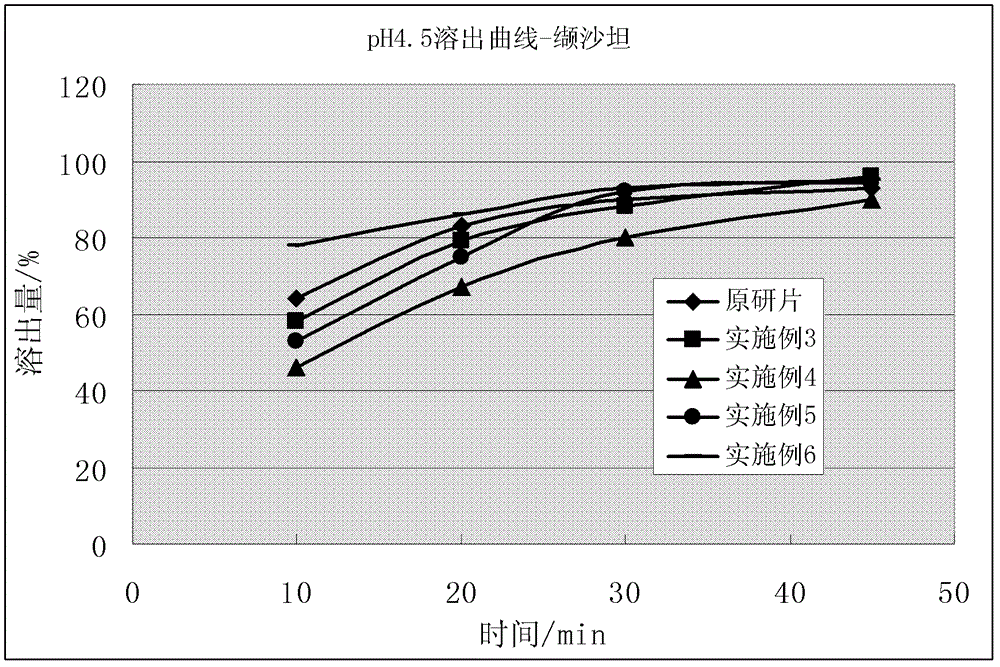

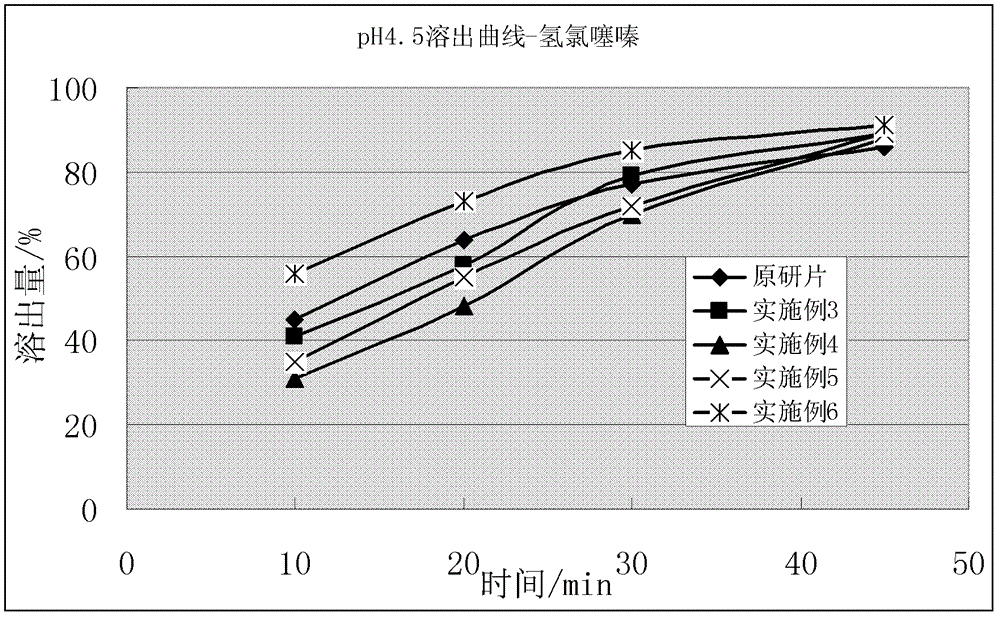

Compound solid preparation of valsartan and hydrochlorothiazide, and preparation method thereof

ActiveCN102247376BEasy to operateLow equipment requirementsDrageesCardiovascular disorderHydrochlorothiazideLubricant

The invention belongs to the field of pharmaceutical preparation, and relates to a compound solid preparation of valsartan or pharmaceutically acceptable salts thereof and hydrochlorothiazide, and a preparation method thereof. The pharmaceutical composition provided by the invention is processed from the following raw and auxiliary materials in percentage by weight: 25-35% of valsartan or pharmaceutically acceptable salts thereof, 2-20% of hydrochlorothiazide, 25-71.4% of microcrystalline cellulose, 1-5.3% of partially pregelatinized starch, 0-20% of disintegrant, 0.5-5% of flow aid and 0.1-5% of lubricant, wherein the weight ratio of the microcrystalline cellulose to the partially pregelatinized starch is requested not to be less than 5:1.

Owner:CHINA RESOURCES SAIKE PHARMA

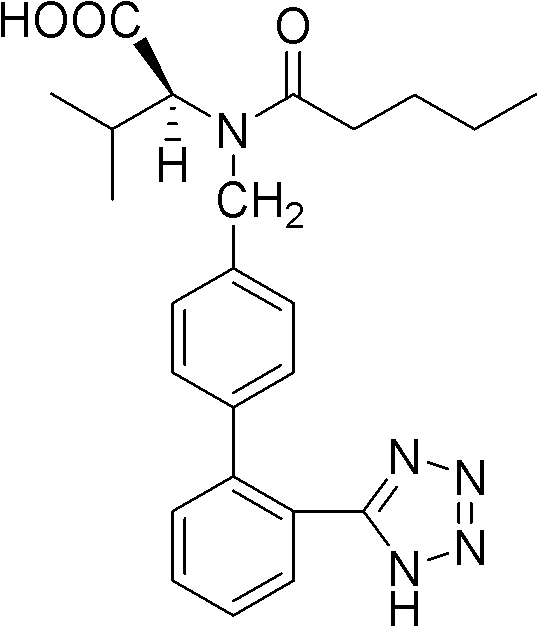

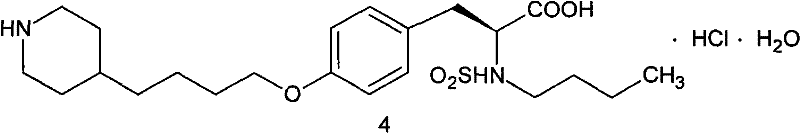

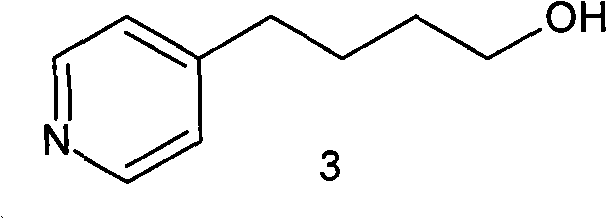

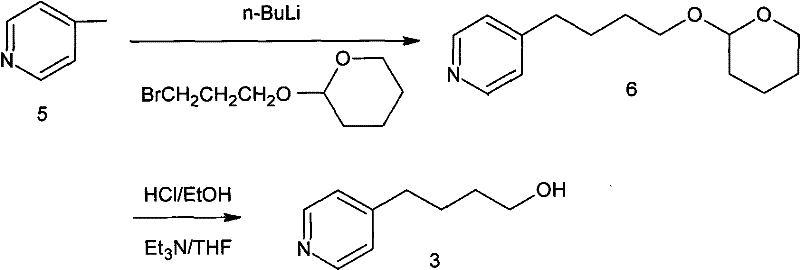

Method for preparing tirofiban hydrochloride intermediate

The invention relates to a method for preparing a compound, in particular to a method for preparing 4-(4-pyridyl)-1-butanol which is a tirofiban hydrochloride intermediate. The preparation method has high yield, causes little waste solid, liquid and gas, ensures high product purity and successfully realizes industrial production.

Owner:WUHAN WUYAO SCI & TECH

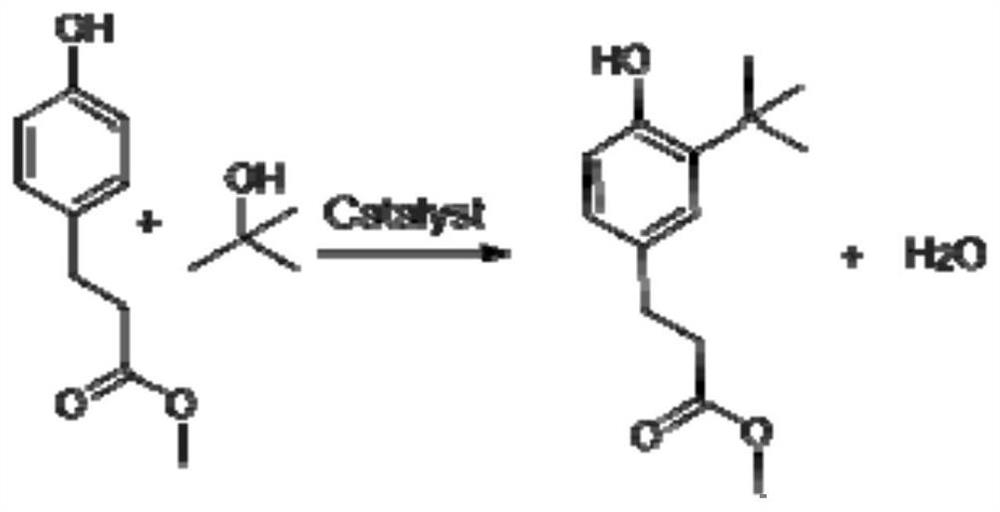

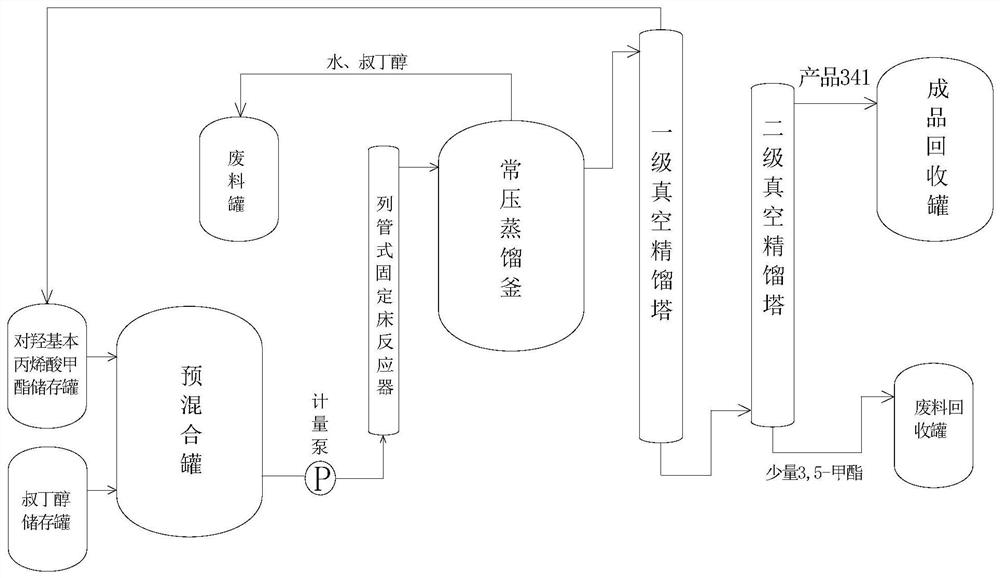

Synthesis process of methyl 3-(3-tert-butyl-4-hydroxy) phenylpropionate

InactiveCN112479877AImprove conversion rateIncrease profitOrganic compound preparationCarboxylic acid esters preparationPropanoic acidPtru catalyst

The invention discloses a synthesis process of methyl-3-(3-tert-butyl-4-hydroxy) phenylpropionate, which comprises the following steps of mixing methyl p-hydroxyphenylpropionate and tert-butyl alcoholaccording to a certain molar ratio, and carrying out continuous reaction in a tubular fixed bed reactor filled with a solid catalyst to obtain a crude product of methyl 3-(3-tert-butyl-4-hydroxy) phenylpropionate, and distilling to remove water with a low boiling point, carrying out secondary separation on residual tert-butyl alcohol through a rectifying tower to obtain a methyl 3-(3-tert-butyl-4-hydroxy) phenylpropionate product. According to the synthesis process, methyl p-hydroxyphenylpropionate and tert-butyl alcohol are used as raw materials, granular solid sulfonic acid resin is used, continuous reaction is performed, secondary separation is performed through a rectifying tower, a high-purity methyl 3-(3-tert-butyl-4-hydroxy) phenylpropionate product is obtained, the yield is high,the quality is excellent, unreacted methyl p-hydroxyphenyl propionate is recycled, so that the method has good industrial production value, and the production cost is reduced.

Owner:JIANGSU JIYI NEW MATERIAL CO LTD

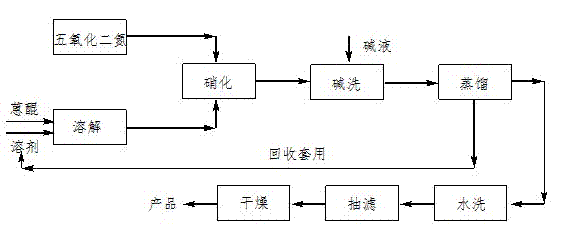

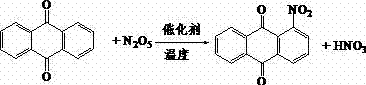

Method for synthesizing 1-nitroanthraquinone by nitration of nitrogen pentoxide

ActiveCN103435492BEasy to getMild reaction conditionsOrganic compound preparationNitro compound preparationOrganic solventReaction rate

Owner:NANJING UNIV OF SCI & TECH

Infra-red devitrified glass fibre and preparation method thereof

InactiveCN101182125BHigh infrared emission efficiencyAvoid the disadvantage of low infrared emission efficiencyGlass making apparatusFiberPliability

The invention discloses infrared microcrystal glass fiber and a preparation method, belonging to the infrared fiber preparation technical field. The infrared microcrystal glass fiber has the comprehensive advantages of high infrared emission efficiency, good flexibility, strong spinnability and good thermal stability. The infrared emission microcrystalline glass fiber uses MgO-Al2O3-SiO2 serial cordierite ceramic formula as main material and is prepared through adding fluxing clarifier, transition metal oxide and additive. Through the melting and the clarification, the fiber is proved with perfect fiber-pulling formability and high infrared emissivity. And the microcrystalline glass fiber with high infrared emissivity is prepared. In the normal temperature environment, the infrared emission microcrystalline glass fiber has the advantages of higher strong toughness and good spinnability and can be widely applied to the textile and the braiding. The fiber can be made into insulation clothing material and can be applied to fields of mechanics, medical treatment, health care, etc.

Owner:TSINGHUA UNIV

A kind of Aureobasidium pullulans using starch to produce polymalic acid and its application

The invention discloses a kind of Aureobasidium pullulans that utilizes starch to produce polymalic acid and its application. Aureobasidium pullulans ) GXL‑1, the deposit number is CCTCC NO: M 2018519, the deposit date is August 1, 2018, the deposit unit: China Center for Type Culture Collection, deposit address: China. Wuhan. Wuhan University. The Aureobasidium pullulans of the present invention ( Aureobasidium pullulans ) GXL‑1 can directly use raw starch or starch liquefaction liquid as the carbon source. Without adding fermentation promoters and growth factors, batch fermentation at 30°C can obtain up to 57g / L of polymalic acid, and no fermentation process occurs. The production of melanin has the advantages of low fermentation cost, easy product purification and simple process, and has great potential for industrial production.

Owner:GUANGXI UNIV

oscilloscope

ActiveCN104020331BEasy to carryEasy to useDigital variable/waveform displayWireless transceiverSignal conditioning

Owner:广东威而信实业有限公司

Method for synthesizing chloramphenicol

ActiveCN102399160BHigh purityHigh yieldOrganic compound preparationCarboxylic acid amides preparationBenzaldehydeNitration

The invention relates to a method for synthesizing a broad spectrum antibiotic, namely, chloramphenicol. The method comprises the following steps of: synthesizing (R)-2-nitro-1-benzylcarbinol by using benzaldehyde and nitromethane as raw materials in the presence of a chiral catalyst; reacting with formaldehyde to obtain (1R,2R)-2-nitro-1-benzyl-1,3-propanediol, and performing hydrogenation reduction to obtain (1R,2R)-2-amino-1-benzyl-1,3-propanediol; and performing dichloro acetylization and nitration on the (1R,2R)-2-amino-1-benzyl-1,3-propanediol to obtain the chloramphenicol. By the method, the common chiral resolution and aluminum isopropoxide reduction in the industry at present can be avoided, three wastes are reduced, the raw materials and reagents are cheap and readily available, the method comprises a few synthesizing steps, the yield is high, and the method is more suitable for industrial production.

Owner:WUHAN WUYAO SCI & TECH

Method for synthesizing chloramphenicol from nitromethane

ActiveCN102399164BHigh purityHigh yieldOrganic compound preparationCarboxylic acid amides preparationP-chlorobenzaldehydeNitromethane

The invention relates to a method for synthesizing a broad spectrum antibiotic of chloramphenicol. The method comprises the following steps of: synthesizing (R)-2-nitro-1-(4-chlorophenyl)ethanol by using p-chlorobenzaldehyde and nitromethane as raw materials in the presence of a chiral catalyst; reacting with formaldehyde to obtain (1R,2R)-2-nitro-1-(4-chlorophenyl)-1,3-propanediol, and performing catalytic hydrogenation to obtain (1R,2R)-2-amino-1-(4-chlorophenyl)-1,3-propanediol; and performing nitro substitution and dichloro acetylization on the intermediate to obtain the chloramphenicol. By the method, the common chiral resolution and aluminum isopropoxide reduction in the industry at present can be avoided, three wastes are reduced, the raw materials and reagents are cheap and readily available, the method comprises a few synthesizing steps, the yield is high, and the method is more suitable for industrial production.

Owner:WUHAN WUYAO SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com