Air filter stick provided with resistance-increasing fixed pieces

An air filter and hollow technology, applied in the direction of smoke oil filter, application, tobacco, etc., can solve the problems of not achieving the expected effect of the inventor, the loss of smoke, and the inability to taste tobacco, etc., to achieve good industrial production value, easy to manufacture and The effect of simple use and structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

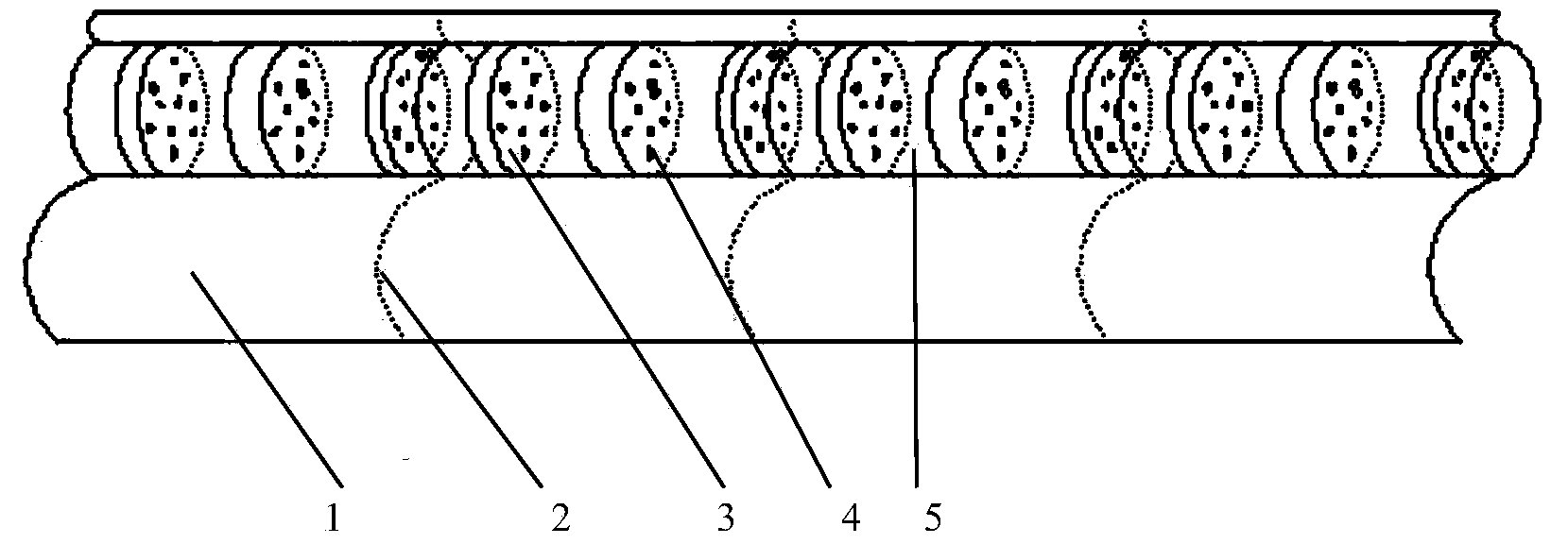

[0023] Such as figure 1 As shown, a plurality of solid sheets 3 are obtained by rolling and cutting regenerated cellulose cellophane, the diameter of the solid sheets is 8mm, and the thickness of a single sheet is 2mm. Each sheet is distributed with 10-20 gas flow channels 4, and the average inner diameter of the flow channels is 0.2 mm.

[0024] Set 9 solid sheets in a molding paper with a width of 100 mm, and roll them into a cylindrical shape. Wherein, a cavity 5 is provided between the two connected solid sheets, and the length of the cavity is 8mm.

[0025] Cut the 100mm long air filter rod into 3 sections along the dividing line.

Embodiment 2

[0027] The same production as in Example 1, the difference is that the thickness of the solid sheet is 5mm, each sheet is distributed with 6-8 gas flow channels, and the average inner diameter of the flow channels is 0.5mm.

[0028] Set 9 solid sheets in a molding paper with a width of 100 mm, and roll them into a cylindrical shape. Wherein, a cavity 5 is provided between the two connected solid sheets, and the length of the cavity is 5 mm.

Embodiment 3

[0030] The same production as in Example 1, the difference is that the solid sheet has a single thickness of 8mm, each sheet is distributed with 6-8 gas flow channels, and the average inner diameter of the flow channels is 1.0mm.

[0031] Set 9 solid sheets in a molding paper with a width of 100 mm, and roll them into a cylindrical shape. Wherein, a cavity 5 is provided between the two connected solid sheets, and the length of the cavity is 2mm.

[0032] Example 3

[0033] The same production as in Example 1, the difference is that the solid sheet has a single thickness of 10 mm, and each sheet is distributed with 20 gas flow channels, and the average inner diameter of the flow channels is 0.3 mm.

[0034] Set 6 solid sheets in the molding paper with a width of 100 mm, and roll them into a cylindrical shape. Wherein, a cavity 5 is provided between the two connected solid sheets, and the length of the cavity is 10 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com