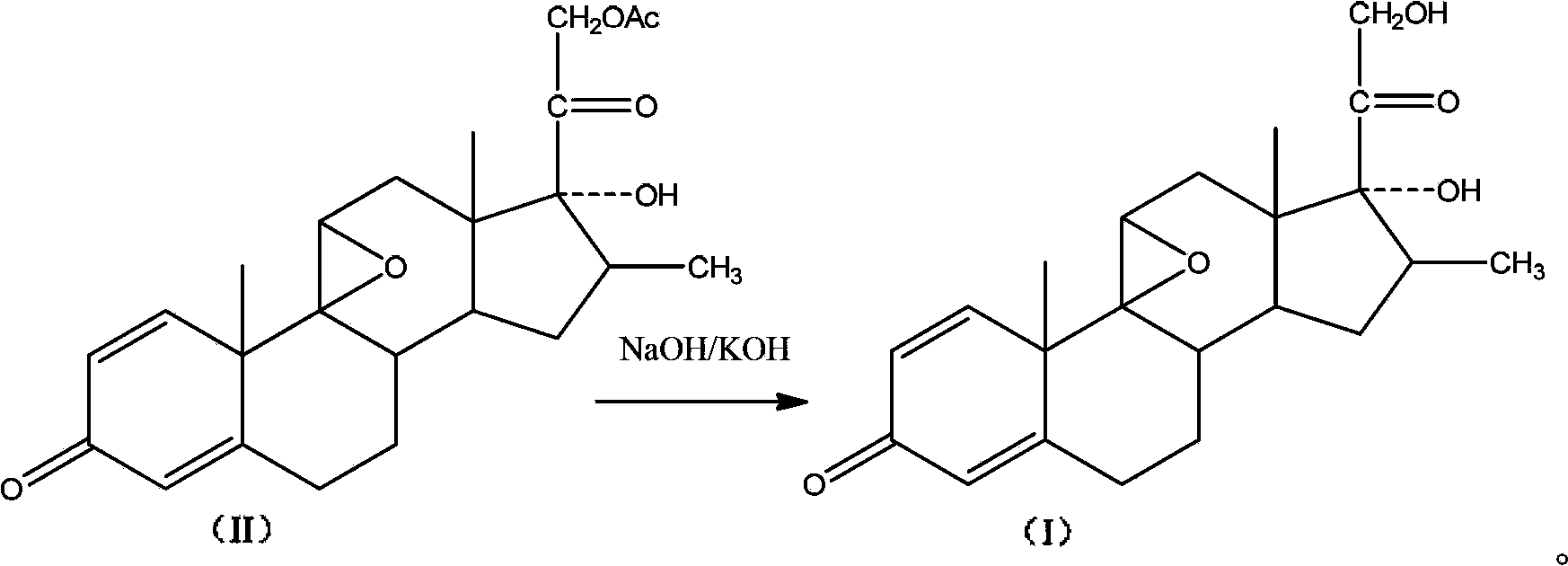

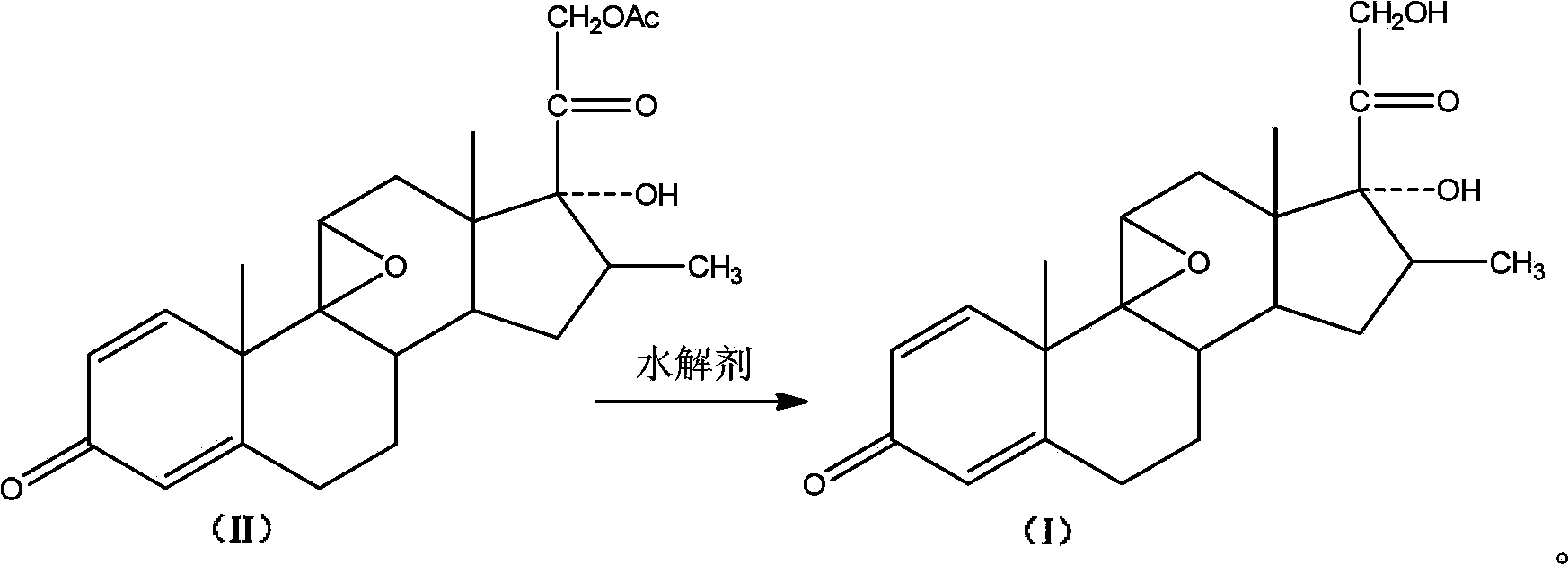

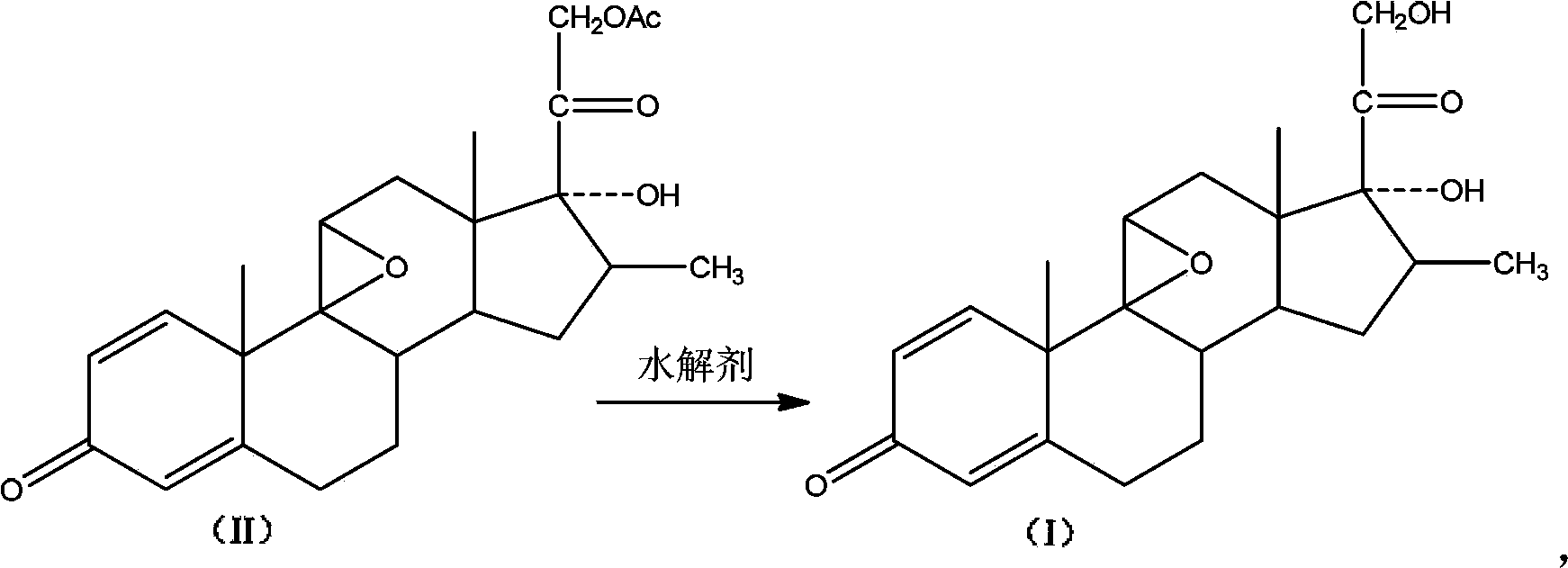

Preparation method of betamethasone intermediate

A technology for betamethasone and intermediates, which is applied in the field of preparation of betamethasone intermediates, can solve problems such as low yield and side chain degradation, and achieve the effects of high yield, good quality, and good industrial production value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Add 20g of betamethasone replacement (II) into a 1000ml three-necked bottle, add 600ml of methanol and 120ml of dichloromethane, heat up to reflux, reflux for 15 minutes, add dropwise 30ml of 20% sodium sulfite solution for hydrolysis reaction, after the reaction is complete, use glacial acetic acid Neutralize to pH=6.5, concentrate the reaction solution under reduced pressure at 40°C to 50°C to near dryness, pour into tap water for water analysis, filter, wash the filter cake with water, dry to obtain 17.5g of betamethasone hydrolyzate (I), and detect by HPLC The content is 98.2%.

Embodiment 2

[0023] Add 20g of betamethasone replacement (II) into a 1000ml three-neck flask, add 800ml of methanol and 100ml of dichloromethane, heat up to reflux, reflux for 15 minutes, add 40ml of 20% sodium sulfite solution dropwise for hydrolysis reaction, after the reaction is complete, use glacial acetic acid Neutralize to pH=6.5, concentrate the reaction solution under reduced pressure at 40°C to 50°C to nearly dryness, pour into tap water for water analysis, filter, wash the filter cake with water, dry to obtain 17.6g of betamethasone hydrolyzate (I), and detect by HPLC The content is 97.8%.

Embodiment 3

[0025] Add 20g of betamethasone replacement (II) into a 1000ml three-necked bottle, add 700ml of methanol and 100ml of dichloromethane, heat up to reflux, reflux for 15 minutes, add 50ml of 20% sodium sulfite solution dropwise for hydrolysis reaction, after the reaction is complete, use glacial acetic acid Neutralize to pH=6.5, concentrate the reaction solution under reduced pressure at 40°C to 50°C to near dryness, pour into tap water for water analysis, filter, wash the filter cake with water, dry to obtain 17.4g of betamethasone hydrolyzate (I), and detect by HPLC The content is 98.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com