Compound amlodipine and valsartan solid preparation and preparation method thereof

A technology for compound amlodipine-valsartan solid preparation is applied in the field of compound amlodipine-valsartan solid preparation and preparation thereof, and can solve the problems of affecting the dissolution of amlodipine, the disparity of amlodipine doses, and the high energy consumption of dry granulation , to achieve the effect of good liquidity, good industrial production value, and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

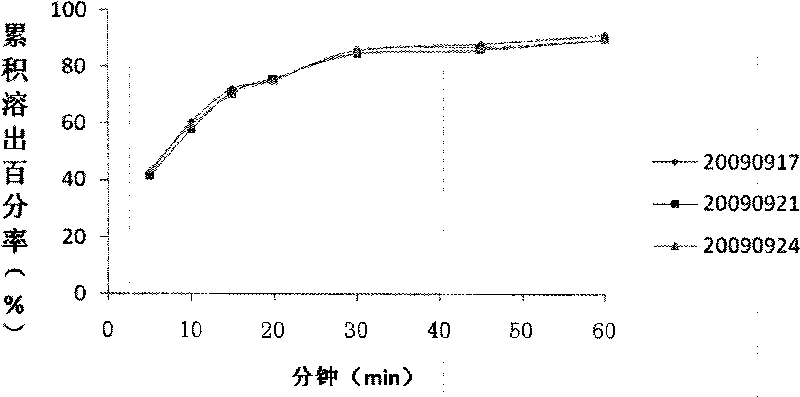

Embodiment 1

[0062] Preparation of Compound Amlodipine-Valsartan Tablets

[0063] The prescription is (per 1000 tablets):

[0064] A: Amlodipine besylate 6.93g *

[0065] B: micronized silica gel 5g

[0066] C: Croscarmellose Sodium 8g

[0067] D: Valsartan 160g

[0068] E: Microcrystalline Cellulose 110g

[0069] F: Lactose 50g

[0070] G: Magnesium stearate 2g

[0071] H: Croscarmellose Sodium 4g

[0072] I: Polyvinylpyrrolidone (K30) 37g

[0073] J: distilled water 900g

[0074] *: Corresponds to 5 g of amlodipine.

[0075] Grind materials A~C, pass through a 100-mesh sieve, and mix uniformly to obtain mixture I; crush materials D~F, pass through a 100-mesh sieve, and mix evenly to obtain mixture II; add mixture I to In mixture II, mix evenly to obtain mixture III; completely dissolve I: polyvinylpyrrolidone (K30) in J: distilled water to obtain a binder; use this binder to granulate mixture II, and control the drying temperature at 45 °C, the water content of the granules i...

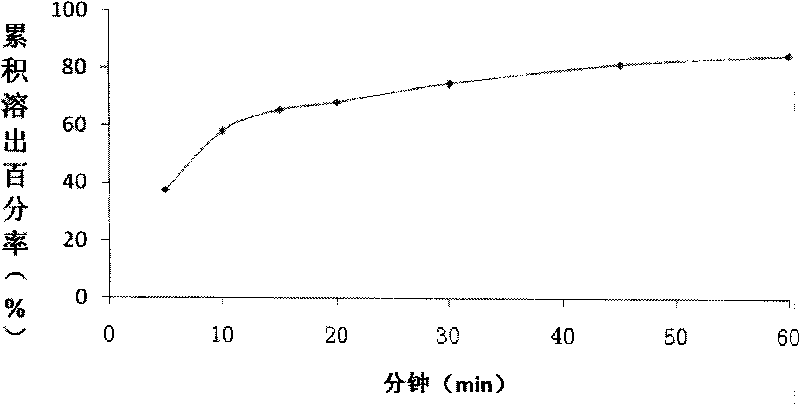

Embodiment 2

[0079] Preparation of compound amlodipine valsartan besylate capsules

[0080] The prescription is (per 1000 capsules):

[0081] A: Amlodipine besylate 6.93g *

[0082] B: micronized silica gel 5g

[0083] C: Croscarmellose Sodium 8g

[0084] D: Valsartan 160g

[0085] E: Microcrystalline Cellulose 110g

[0086] F: Lactose 50g

[0087] G: Magnesium stearate 4g

[0088] H: medicinal talcum powder 2g

[0089] I: Polyvinylpyrrolidone (K30) 37g

[0090] J: distilled water 900g

[0091] *: Corresponds to 5 g of amlodipine.

[0092] Grind materials A~C, pass through a 100-mesh sieve, and mix uniformly to obtain mixture I; crush materials D~F, pass through a 100-mesh sieve, and mix evenly to obtain mixture II; add mixture I to the mixture in equal increments In II, mix evenly to obtain mixture III; completely dissolve I: polyvinylpyrrolidone (K30) in H: distilled water to obtain a binder; use this binder to granulate mixture II, and control the drying temperature at 45°C ...

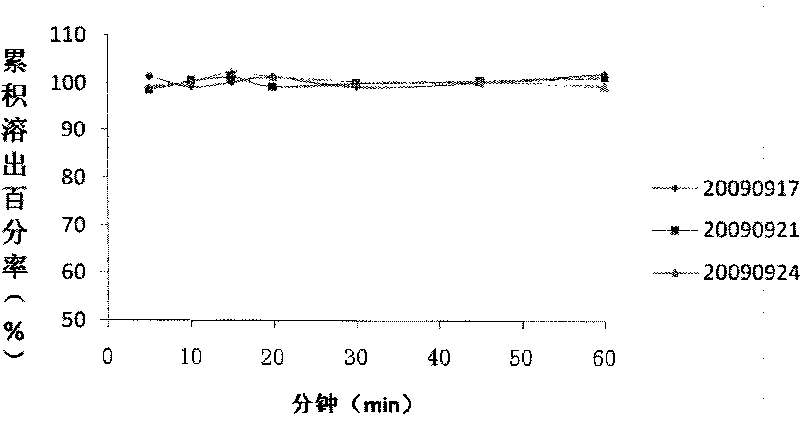

Embodiment 3

[0095] Preparation of Compound Amlodipine-Valsartan Tablets

[0096] The prescription is (per 1000 tablets):

[0097] A: Amlodipine besylate 3.47g *

[0098] B: micronized silica gel 4g

[0099] C: Crospovidone 6g

[0100] D: Valsartan 80g

[0101] E: Microcrystalline cellulose 80g

[0102] F: Lactose 30g

[0103] G: Magnesium stearate 2g

[0104] H: Low-substituted hydroxypropyl cellulose 2g

[0105] I: Hypromellose (E4M) 21g

[0106] J: Distilled water 700g

[0107] *: Corresponds to 2.5 g of amlodipine.

[0108]Grind materials A~C, pass through a 100-mesh sieve, and mix uniformly to obtain mixture I; crush materials D~F, pass through a 100-mesh sieve, and mix evenly to obtain mixture II; add mixture I to In mixture II, mix evenly to obtain mixture III; completely dissolve I: polyvinylpyrrolidone (K30) in J: distilled water to obtain a binder; use this binder to granulate mixture II, and control the drying temperature at 45 °C, the water content of the granules i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com