Preparation method of polycarboxylic acid and flame-retardant epoxy resin thereof

A polycarboxylic acid and epoxy resin technology is applied in the field of materials to achieve the effects of simple and easy synthesis process, mild reaction conditions and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

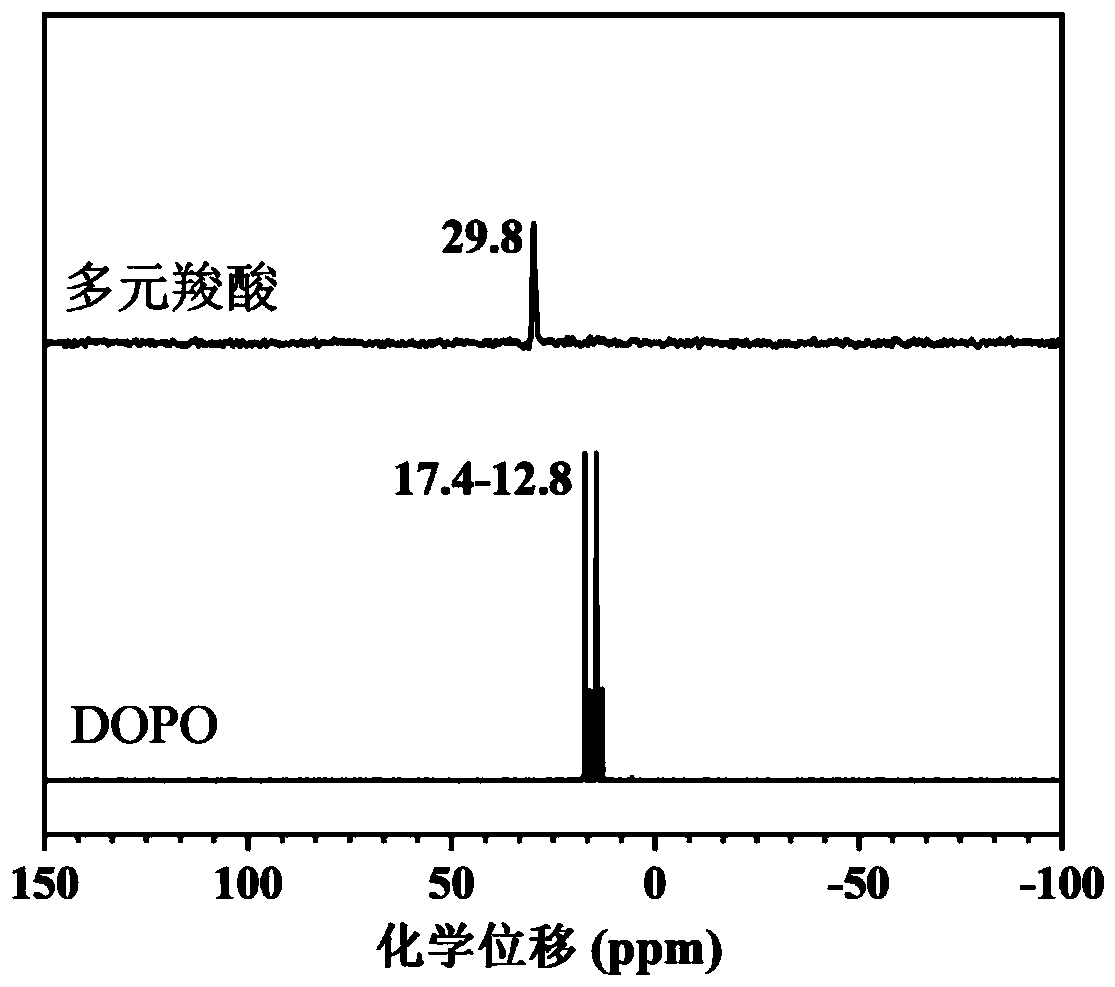

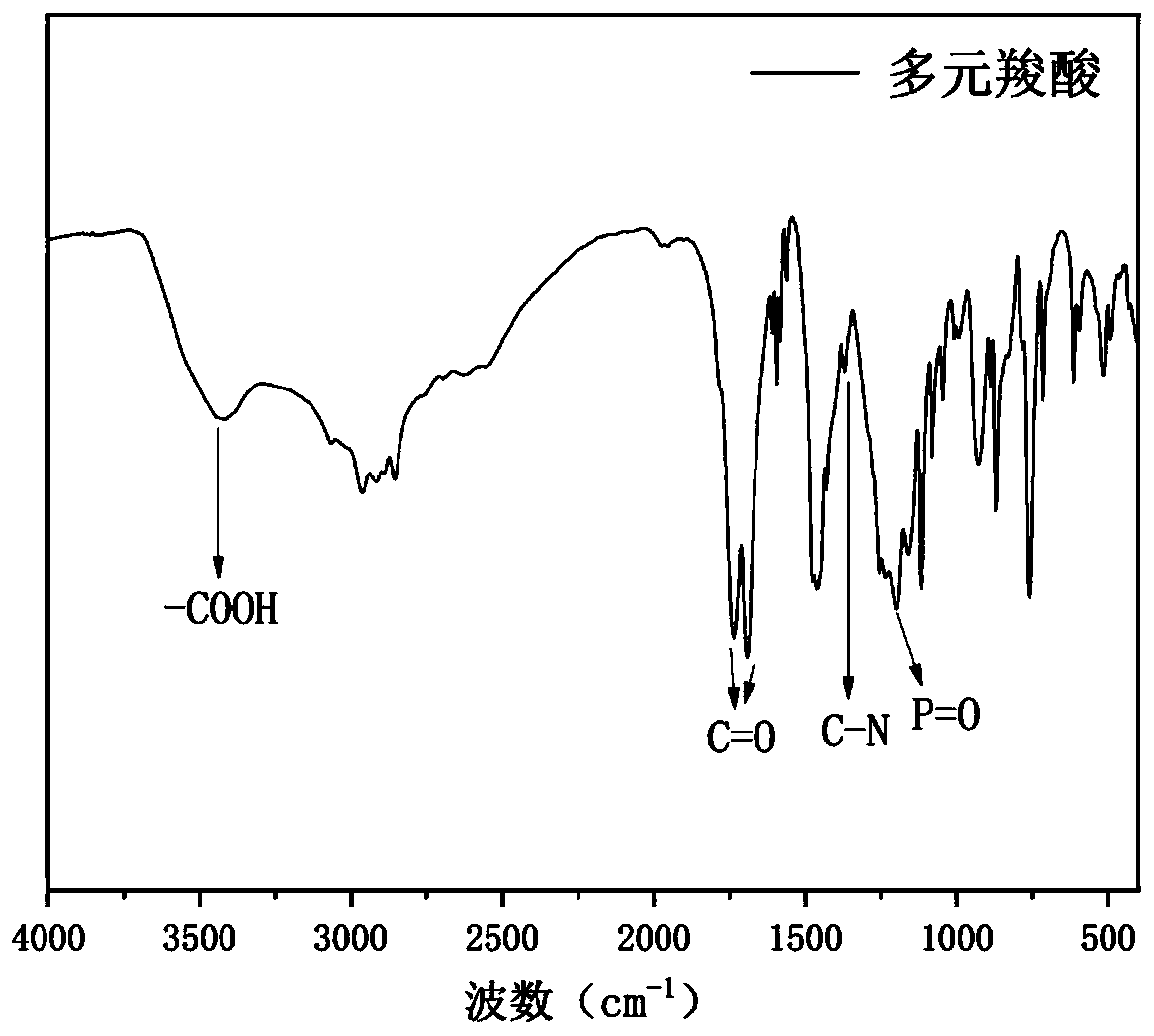

Embodiment 1

[0036] Add 78.3g THEIC, 88.2g MAH and 80mL dioxane into a 500mL round bottom flask equipped with a stirrer, condenser and thermometer, raise the temperature to 95°C, and keep stirring for 2h. Then, 194.4 g of DOPO and 130 mL of dioxane were added to the reaction solution in 5 batches within half an hour, and the temperature was raised to reflux state (about 110° C.), and the stirring was continued for 8 h. The molar ratio of the reaction raw materials is THEIC:MAH:DOPO=1:3:3. After the reaction is completed, dioxane, deionized water and the polarity difference between the product are used for purification. The resulting solution was poured into deionized water and stirred, and filtered to obtain a white viscous liquid. Wash again with plenty of deionized water. Finally, the product was dried in a vacuum oven at 60°C for 24 hours to a constant weight, taken out and ground to obtain 325.2 g of light yellow powder, which was sealed in bags for later use. Get a small amount of ...

Embodiment 2

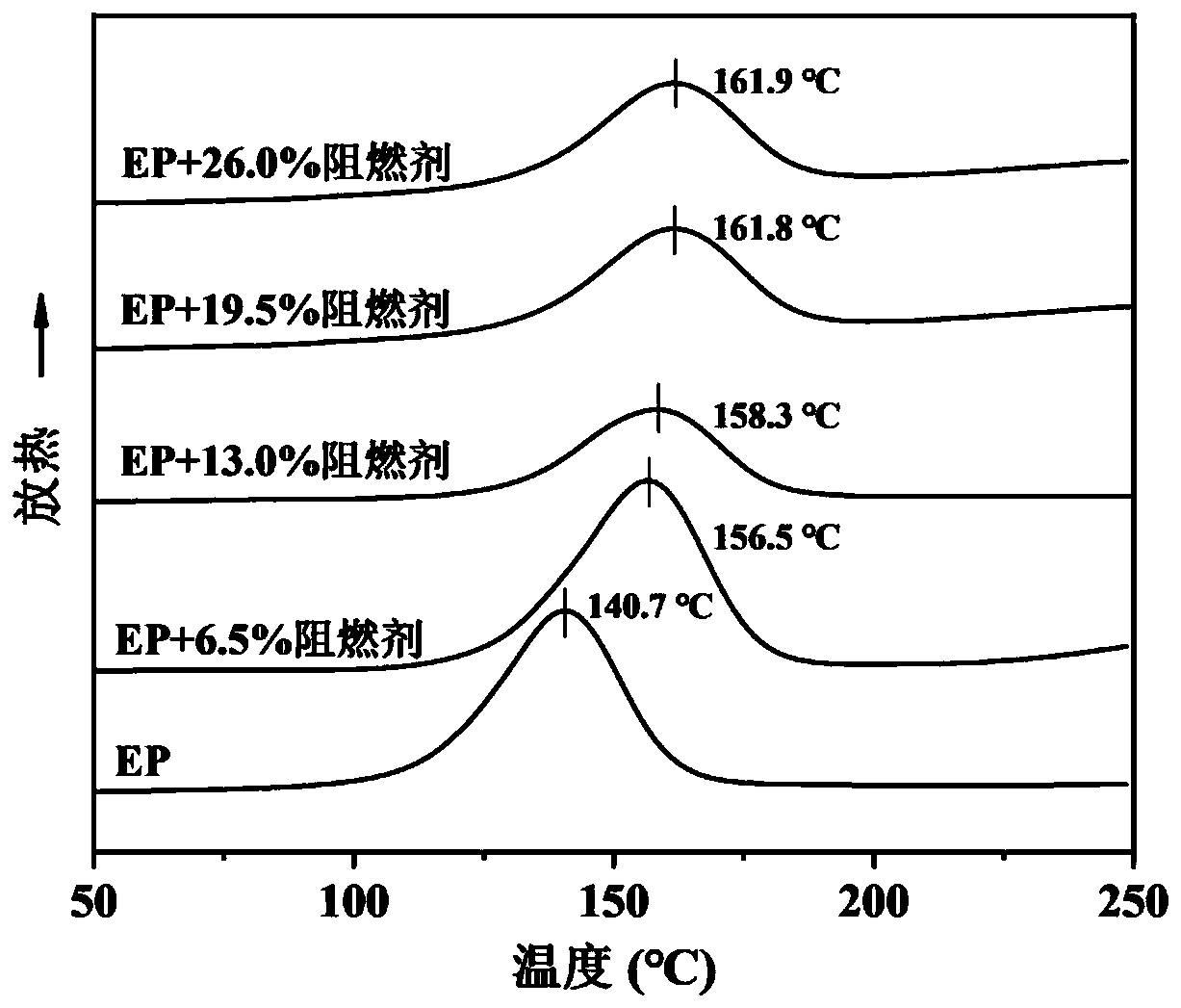

[0038]Weigh 100g of epoxy resin (E-51) and 84.7g of methyltetrahydrophthalic anhydride in a 250mL round bottom flask and stir at room temperature for 10min, then add 0.2wt% of 2,4,6-tri(di Methylaminomethyl) phenol was stirred for 10 minutes, degassed for 5 minutes, then poured into a preheated mold, and cured according to the curing system of 100°C / 4h+130°C / 2h+180°C / 2h+200°C / 2h. After the resin is cured, the sample is prepared according to the standard, and the obtained sample is recorded as EP, which is a reference sample without adding flame retardant.

Embodiment 3

[0040] Add 12.5g of flame retardant and 100g of epoxy resin (E-51) into a 250mL round bottom flask equipped with a stirrer and a thermometer, stir evenly at 130°C (about 1h), then add 79.5g of methyltetrahydrophthalate Diformic anhydride, stop heating, and then add 0.2wt% 2,4,6-tris(dimethylaminomethyl)phenol when the temperature drops to 75°C, stir for 10 minutes, degas for 5 minutes, and then pour into the preheated mold In the middle, the curing is carried out according to the curing system of 100°C / 4h+130°C / 2h+180°C / 2h+200°C / 2h. After the resin is cured, prepare a sample according to the standard, and the obtained sample is marked as EP-1, and the flame retardant content is 6.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com