Automatic acid preparation method and device for phosphoric acid in sugar refinery

A phosphoric acid and acid compounding technology, applied in chemical instruments and methods, sucrose production, sugar production, etc., can solve problems such as difficult to obtain accurate values, difficult to ensure the accuracy, timeliness and stability of phosphoric acid, and achieve the method Simple, easy to operate and ensure the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

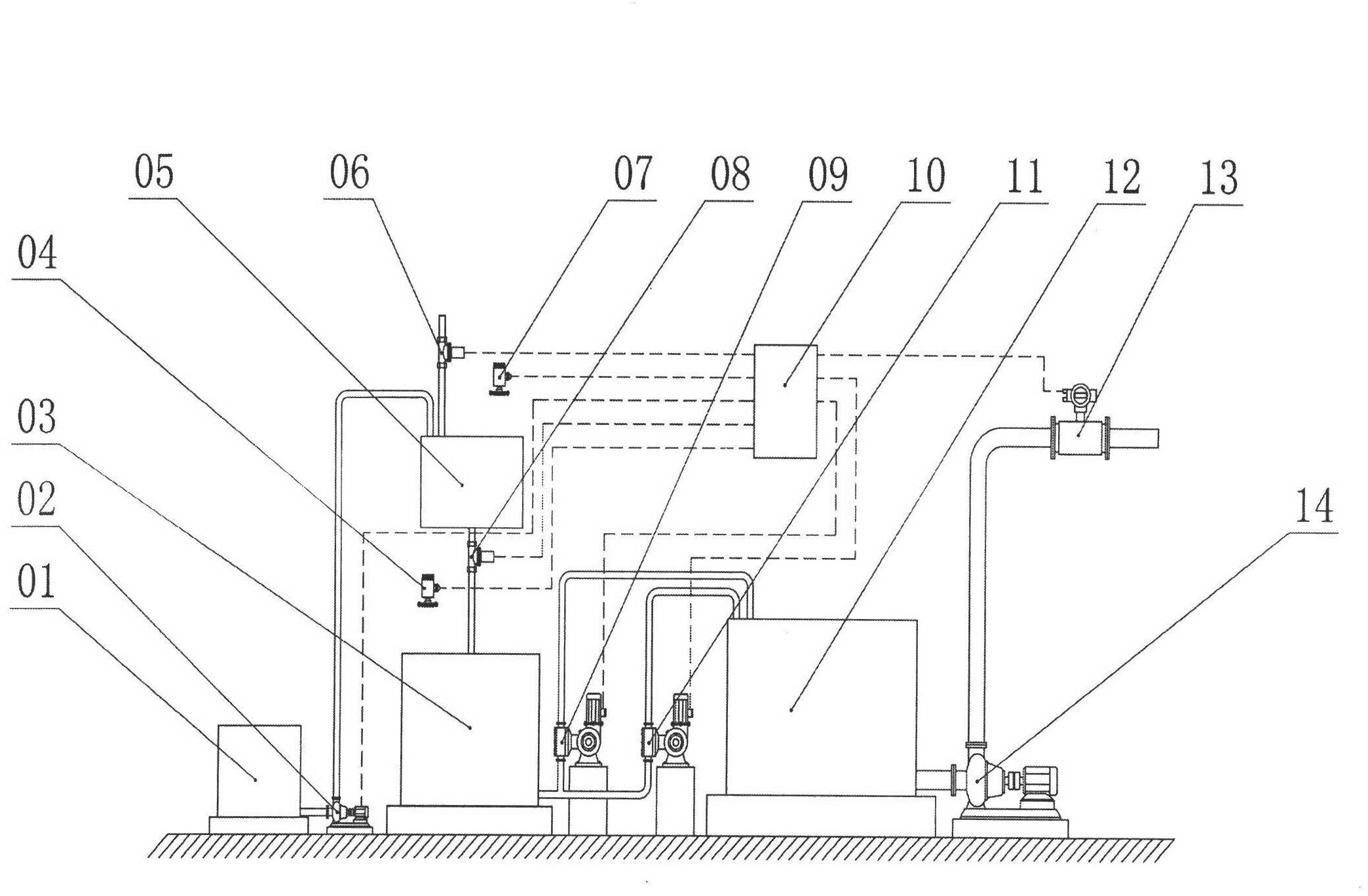

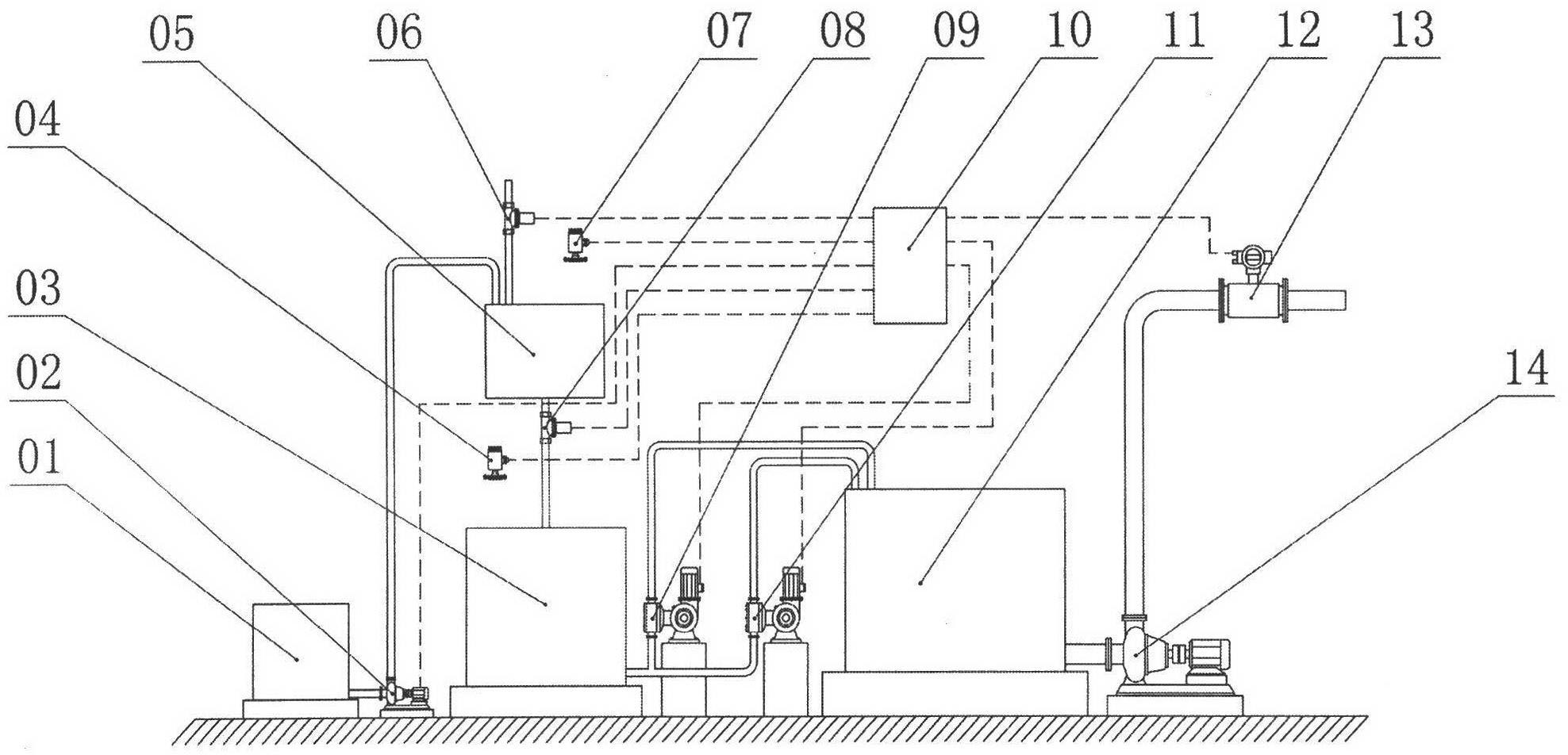

[0016] Such as figure 1 As shown, the phosphoric acid automatic acid dispensing device of the present invention includes a concentrated phosphoric acid storage tank 01, a dilute phosphoric acid storage tank 03 and a dilute phosphoric acid proportioning tank 05. A concentrated phosphoric acid pump 02 is connected to the dilute phosphoric acid pump 02 at the outlet of the concentrated phosphoric acid storage tank 01 through a concentrated acid delivery pipe. Phosphoric acid proportioning box 05, the dilute phosphoric acid proportioning box 05 is at the high position, through the pipeline and the acid discharge solenoid valve 08 to the dilute phosphoric acid storage tank 03, the dilute phosphoric acid storage tank 03 has a clear water pipe and a water filling solenoid valve 06, and the dilute phosphoric acid storage tank 03 is equipped with dilute phosphoric acid storage tank liquid level gauge 04 and matching acid liquid level gauge 07, metering pump 09 is installed between dilut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com