High-performance polycarboxylate water reducer

A polycarboxylic acid-based, water-reducing agent technology, applied in the field of concrete admixtures, can solve the problems of difficulty in control, affecting the quality of high-performance concrete, single performance, etc., and achieves small slump loss, high water reduction rate, and adsorption effect. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

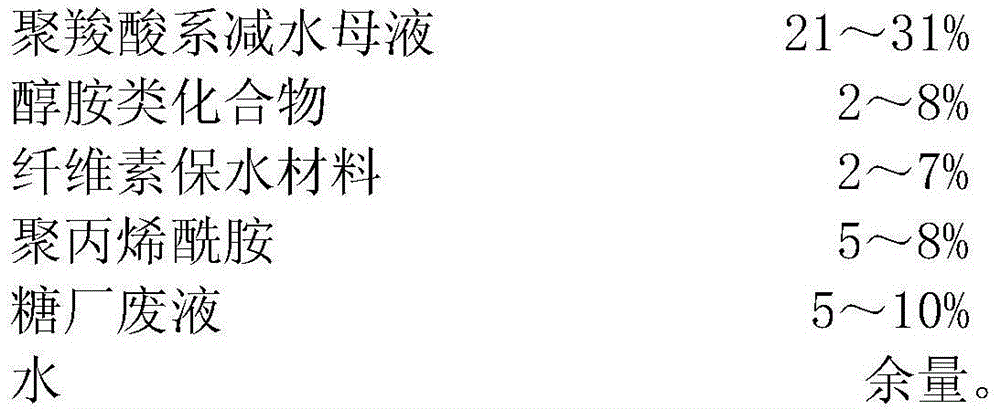

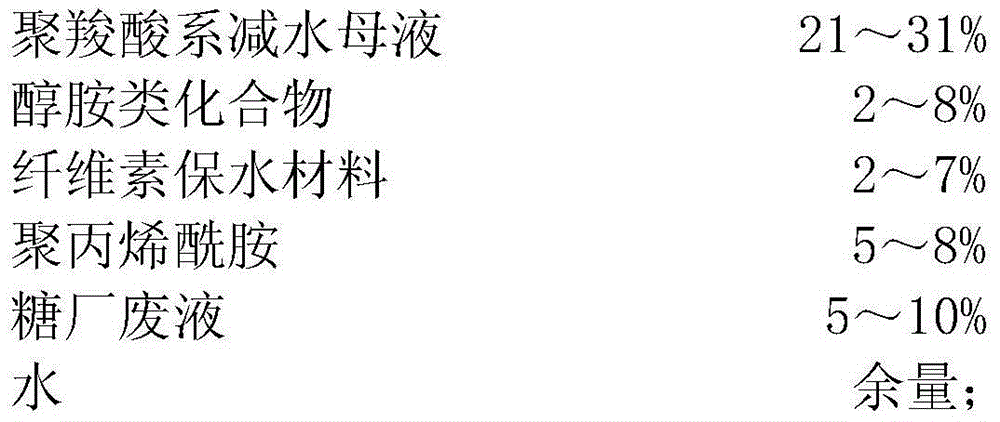

Method used

Image

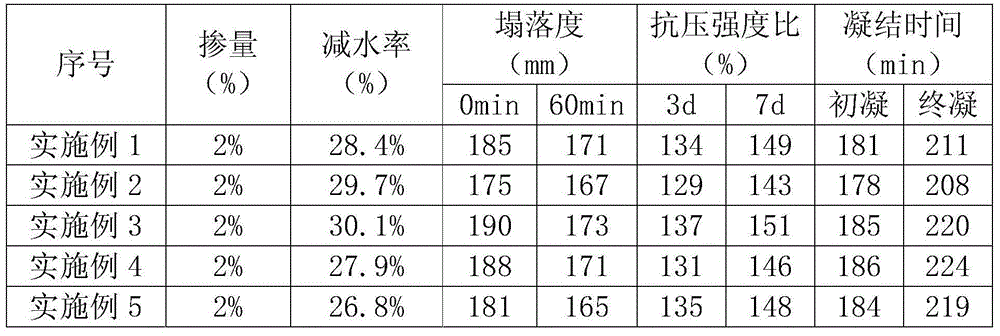

Examples

Embodiment 1

[0023] Take the following raw materials by weight percentage: solid content is 45wt.% acrylic polycarboxylate water-reducing mother liquor 21%, triethanolamine 8%, methylcellulose 7%, polyacrylamide 5%, Baume degree is 35 °Bé's sugar factory waste liquid 10%, water 49%;

[0024] Mix acrylic polycarboxylate water-reducing mother liquor, sugar factory waste liquid and water evenly, then add triethanolamine, methyl cellulose, and polyacrylamide, stir evenly, and stir for 10 minutes to obtain the product.

Embodiment 2

[0026] Weigh the following raw materials by weight percentage: 23% of methacrylic polycarboxylic acid water-reducing mother liquor with a solid content of 44wt.%, 7% of diethanol monoisoalcoholamine, 6% of hydroxyethyl methylcellulose, polypropylene Amide 6%, Baumé 9% of sugar factory waste liquid of 36°Bé, water 49%;

[0027] Mix the methacrylic polycarboxylic acid water-reducing mother liquor, sugar factory waste liquid and water evenly, then add diethanol monoisoolamine, hydroxyethyl methylcellulose, polyacrylamide, stir evenly, and stir for 15 minutes. Instantly.

Embodiment 3

[0029] Weigh the following raw materials by weight percentage: 26% of maleic anhydride water-reducing polycarboxylic acid series mother liquor with a solid content of 43wt.%, 5% of triisopropanolamine, 4% of hydroxypropyl methylcellulose, polypropylene Amide 6%, Baumé 8% of sugar factory waste liquid of 38°Bé, water 51%;

[0030] Mix maleic anhydride-based polycarboxylic acid water-reducing mother liquor, sugar factory waste liquid and water evenly, then add triisopropanolamine, hydroxypropyl methylcellulose, polyacrylamide, stir evenly, and stir for 20 minutes, that is have to.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com