Novel water jet condenser with multiple closed water chambers and jet flow control valve

A water jet condenser and jet adjustment technology, applied in the field of vacuum systems, can solve the problems of shortening the cooking time, reducing the vacuum degree of the condenser, not meeting the requirements of the sugar cooking process, etc., and achieve the effect of improving the recovery rate of cooking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

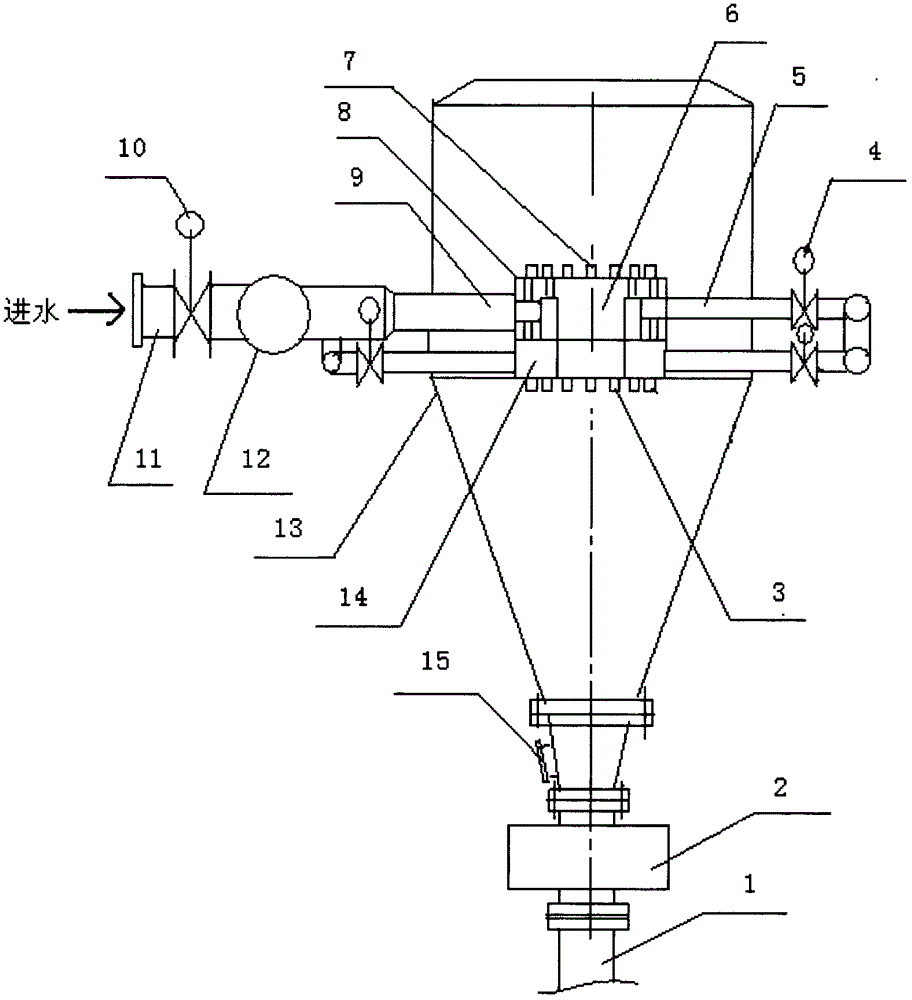

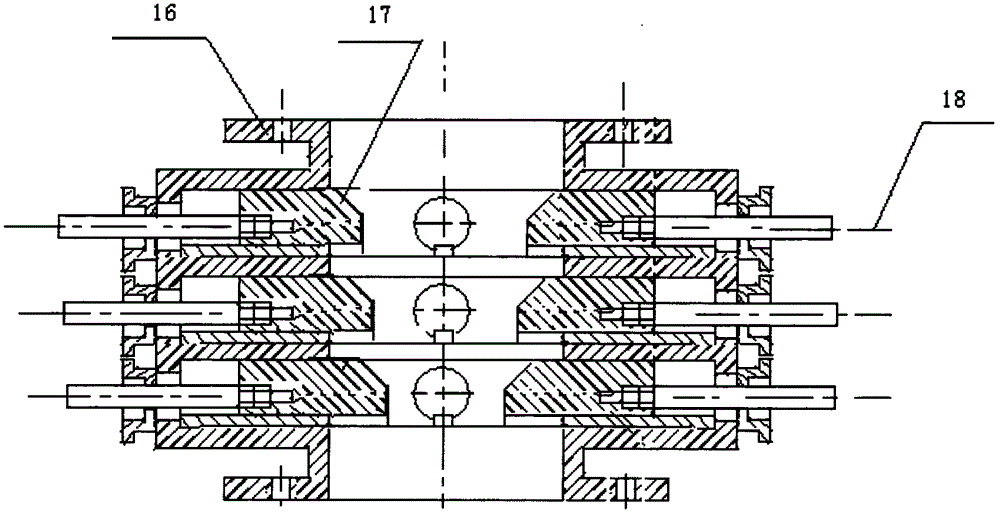

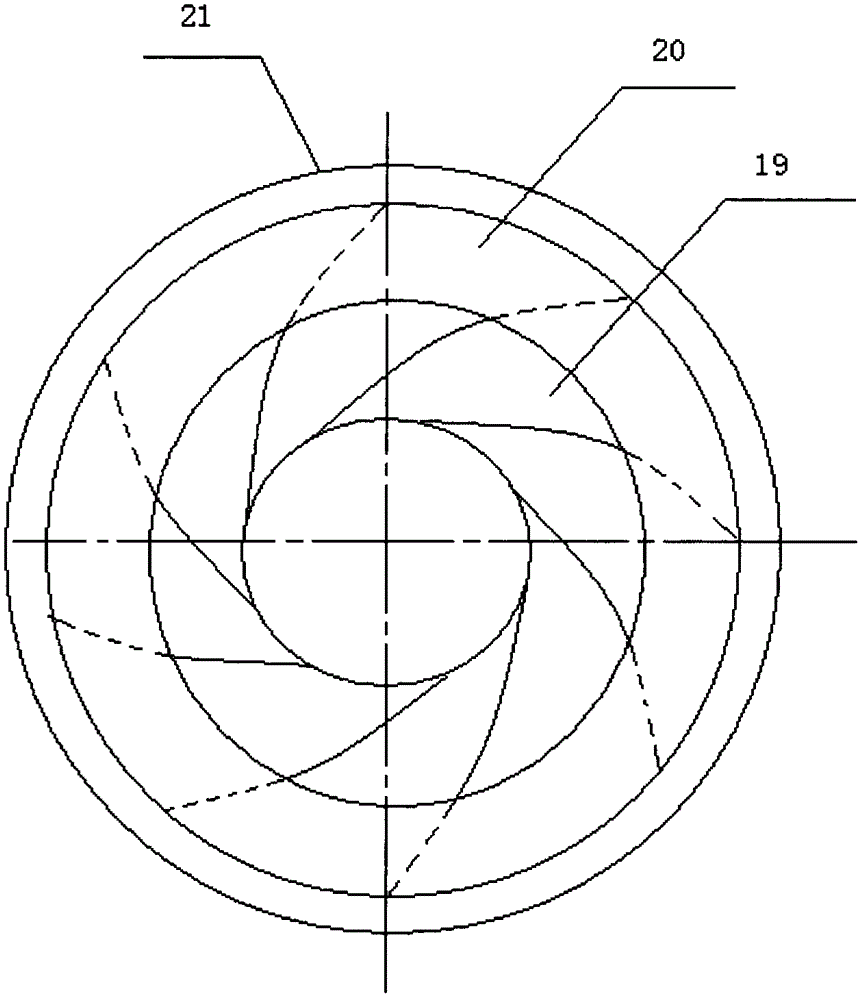

[0024] figure 1 It is a structural schematic diagram of a novel multi-closed water chamber and a jet regulating valve water jet condenser of the present invention, figure 1 The body (13) has been sectioned in the middle. In the figure, the lower flower plate in the water jet tube (8) in the body (13) is separated into a large water chamber (6) with an open top and several small water chambers (14) with a closed top. , the open large water chamber (6) is supplied with water by the water inlet pipe (9), and several small water chambers (14) with closed tops are respectively supplied with water by several water inlet pipes (5), and each water inlet pipe (5) A pneumatic or electric butterfly valve (4) mounted on the outside of the condenser is arranged on the upper part to control the water intake of the small water chamber (14); A spray nozzle (7) and spray nozzle (3), also be provided with a plurality of spray nozzles (3) on the lower flower plate in each airtight small water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com