Method for producing micro organic matters by marine culture sludge and sugar refinery filtration sludge

A microbial fertilizer and mariculture technology, which is applied in the field of microbial fertilizer production from mariculture sludge and sugar factory filter mud, can solve problems such as low-efficiency production, low fertilizer efficiency, and low-efficiency productivity, so as to improve soil, change the characteristics and effects of chemical fertilizers significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

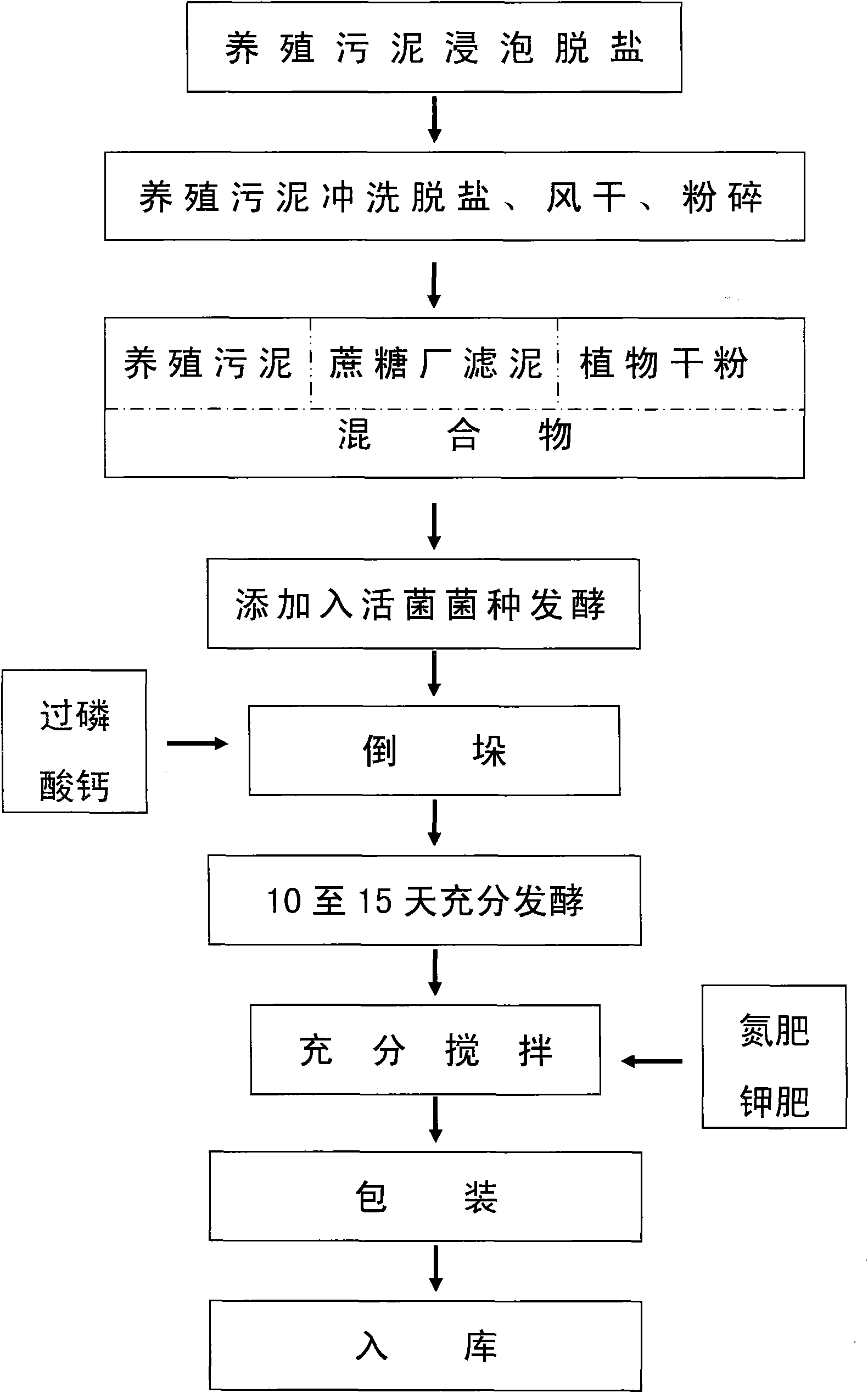

[0025] 1. Implementation steps

[0026] (1) Drain the accumulated water in the breeding pond, expose to the sun until it cracks, soak in water for 10 days, then drain it and expose it to the sun until it cracks, repeating this many times.

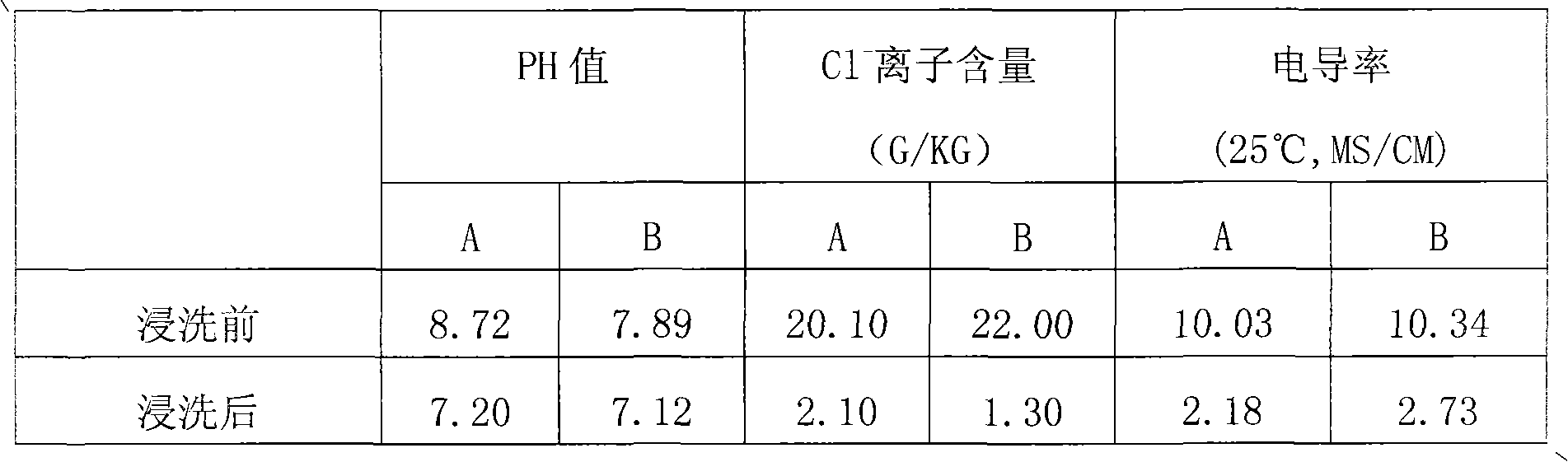

[0027] (2) Measure the Cl of the sample after air-drying respectively - Concentration, PH value, conductivity and other indicators;

[0028] (3) Rinse, drench, and elute salt from the dried mariculture sludge to make the water-to-soil mass ratio 5:1, stir at 25° C. for 8 minutes, filter, and air-dry.

[0029] (4) Collect the filtrate and measure the content of nitrogen and phosphorus. Determination of Cl in air-dried sludge after soaking - Concentration, PH value, conductivity and other indicators.

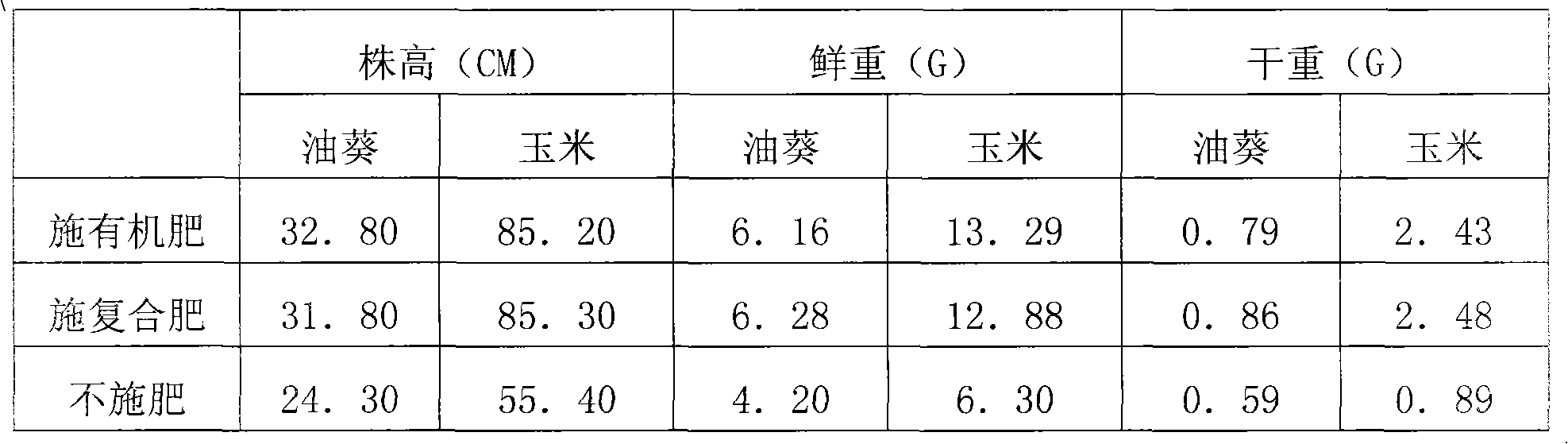

[0030] (5) Mix the air-dried mariculture sludge after soaking, sugar factory filter mud and peanut straw dry powder in a ratio of 4:3:2 (mass ratio). Add 2 kg of Bacillus subtilis species to the mixture for anaerobic fermentation, and dete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com