Solid liquid high-efficiency separation device for filter mud of sugar refinery

A technology for filtering mud and separating devices in sugar factories, which is applied in the direction of temperature control sludge treatment, dehydration/drying/thickened sludge treatment, etc., which can solve the problems that producers cannot bear and achieve considerable benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

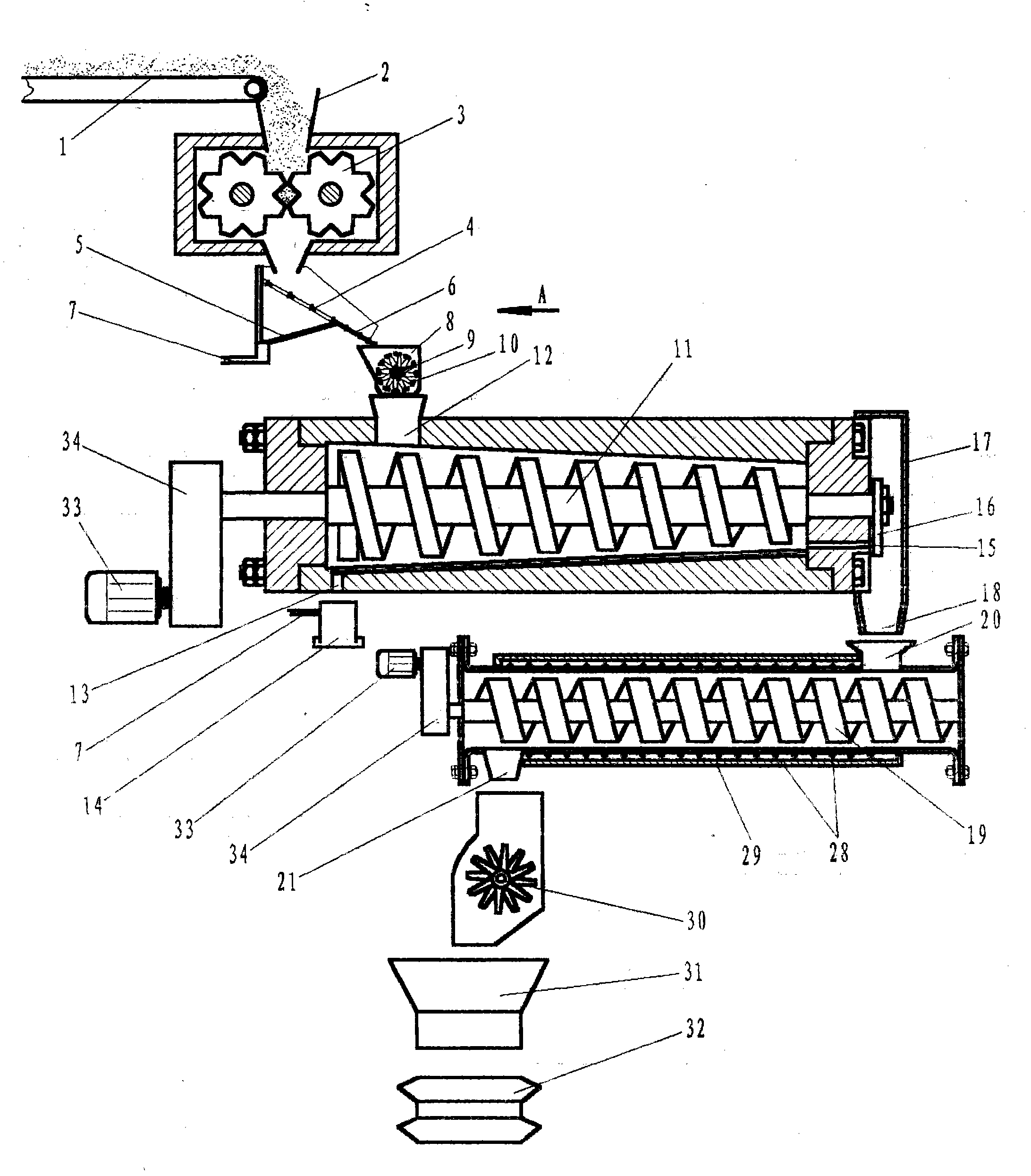

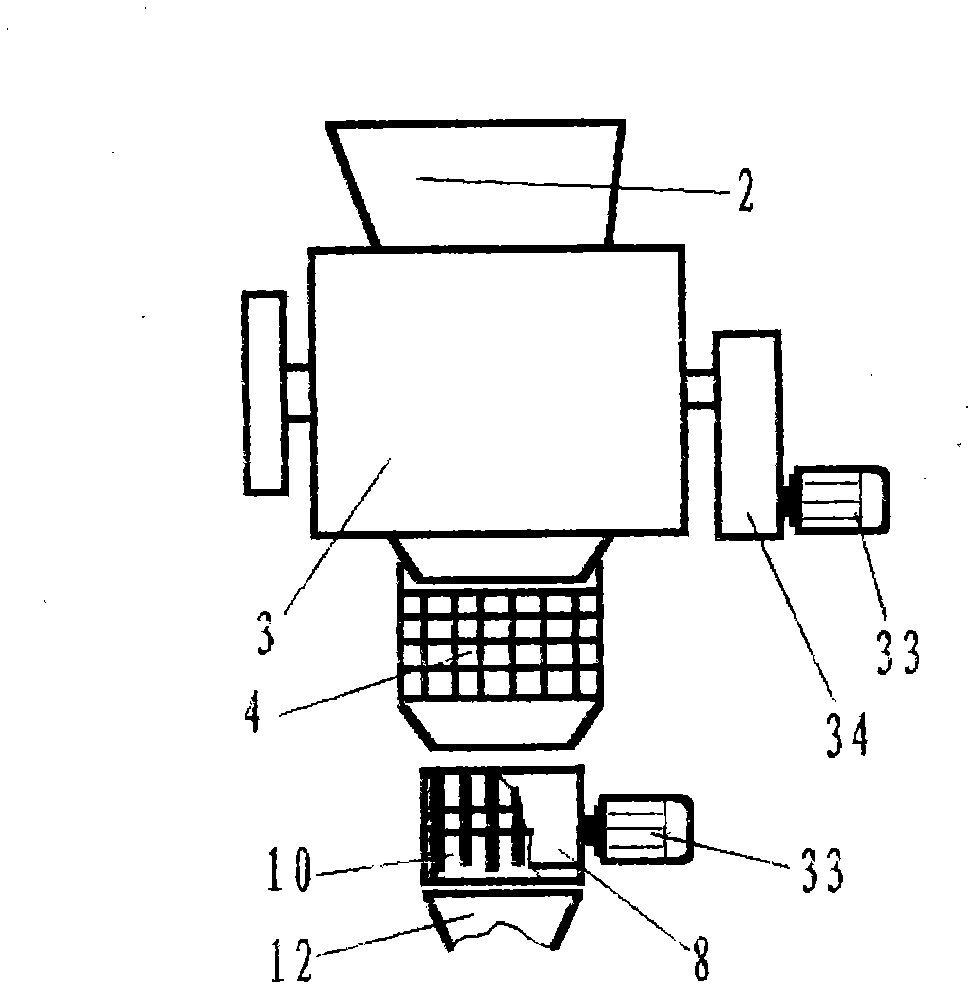

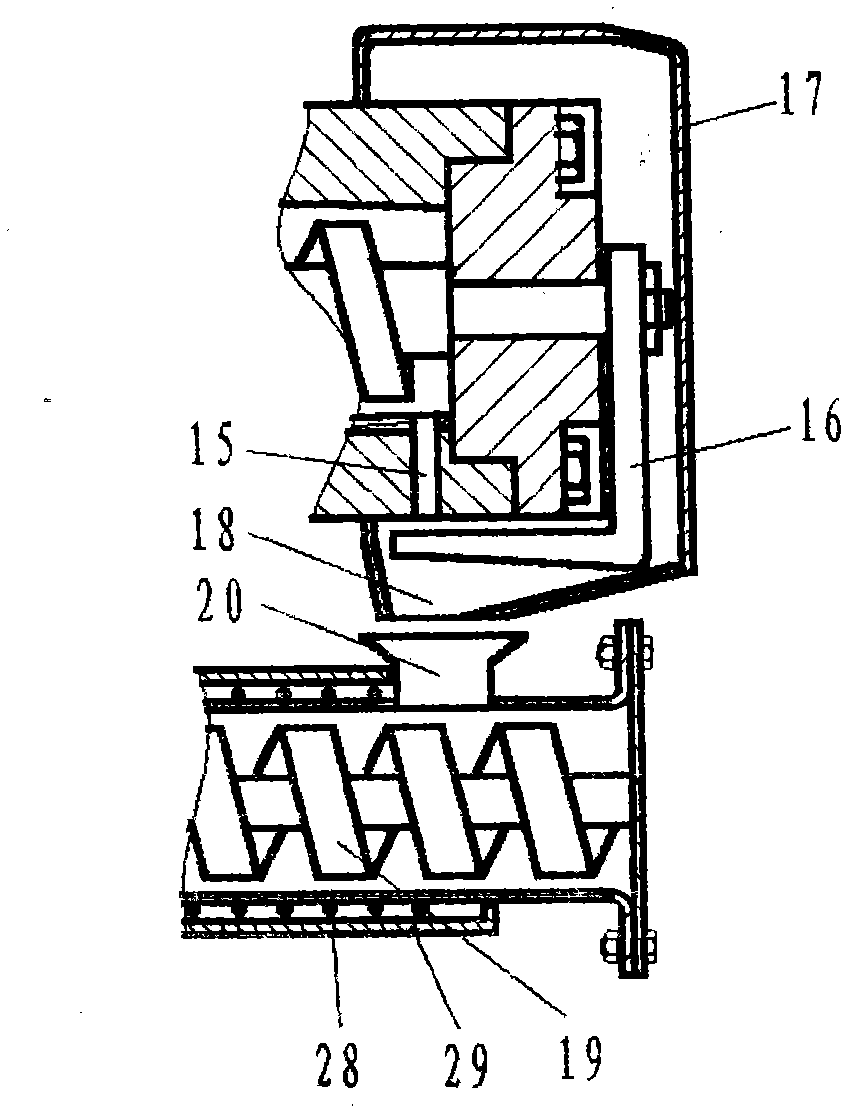

[0009] Refer to attached figure 1 , a wet mud conveyor belt 1 and a mud hopper 2 are arranged at a high position. The discharge end of the wet mud conveyor belt 1 is located above the mud divider 2, and the mud divider 2 is located above the feed port of the double-wheel roller 3, and the discharge port of the mud divider 2 is facing the double-wheel roller 3 feed ports. Below the discharge port of the double-wheel roller 3, there is fixed with a slanting sieve plate 4 (or slanting screen, by figure 2 Can see more clearly) and the mud-water separator 6 that water deflector 5 constitutes. The water outlet of the water guide plate 5 is connected with the return pipe 7 . At the lower end of the inclined sieve plate 4 of the mud-water separator, a mud chopper 8 is arranged. On the rotary cutter shaft 9 of the mud chopper 8, there are many rows of chopping blades 10 (by figure 2 can be seen more clearly). The rotary cutter shaft 9 of the mud block cutter 8 must be parallel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com