Automatic control system for clarification and evaporating process of sugar refinery

An automatic control system and control system technology, applied in the fields of automatic control system, sugar refinery clarification, and evaporation process automatic control system, can solve the problems of unfavorable production process real-time remote management, not automatic control of production process, limited effect, etc., to overcome Fouling, increase packing rate, improve the effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The architecture and implementation of the present invention will be further illustrated and described below in conjunction with the accompanying drawings.

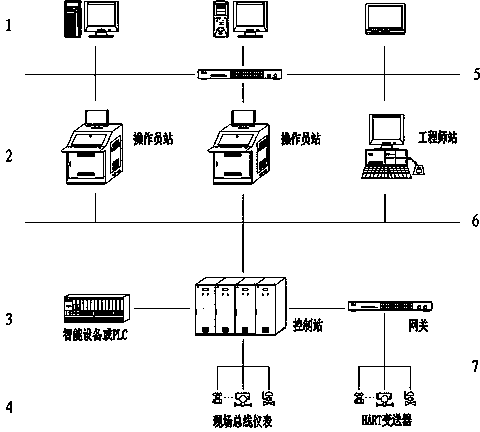

[0033] figure 1 The system architecture diagram of the automatic control system for the clarification and evaporation process of the sugar factory. It can be seen from the diagram that the entire automatic control system architecture is divided into field instrument layer 4, control station 3, engineer station and operator station 2 from bottom to top. Information management layer 1 has four levels, in which the field instrument layer 4 is connected to the control station 3 through the process control network 7, the control station 3 is connected to the engineer and operator station 2 through redundant industrial Ethernet 6, and the engineer and operator station 2 It is connected with the information management layer 1 through the information management network 5 .

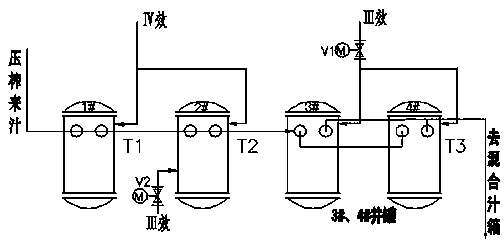

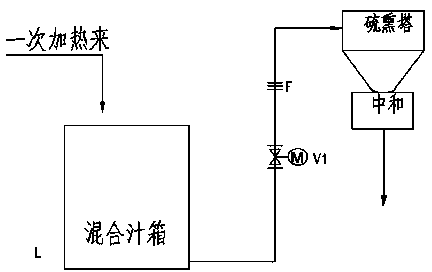

[0034] figure 2 It is the application flowcha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com