Salted goose processing method

A processing method, the technology of salted goose, applied in the field of food processing, can solve the problems of long production cycle, heavy weight loss, long pickling time, etc., and achieve the effect of uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

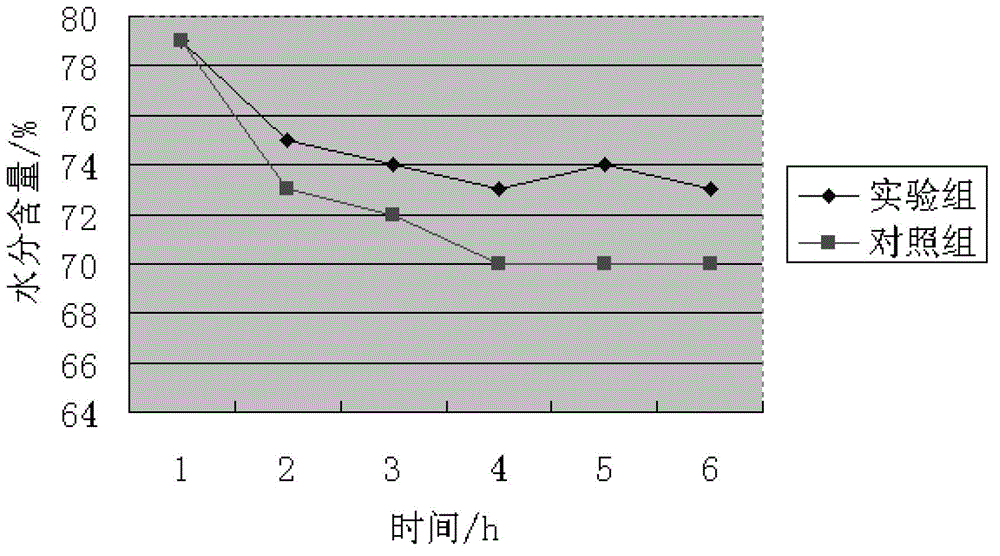

[0022] Slaughter and clean the goose; cover the surface of the goose carcass with a mixture of fragrant leaves, peppercorns, and star anise that are ground into powder and then fried with salt; inject marinade evenly into the goose body, and put the goose into a vacuum tumbler after injection Low temperature, pickling by intermittent cycle vacuum mode; the mass ratio of goose meat and pickling liquid in the vacuum tumbler is 10:3. Multiple cycles were adopted at a low temperature of 3°C. In each cycle, the air in the tumbler was first pumped out to a vacuum of 70 kPa, and kept for 2 hours, and then the atmospheric pressure was restored, and kept for 2 hours. The vacuum tumbler uses a speed of 5 r / min for tumbling, and stops for 0.5h every 15 minutes of tumbling. The processed goose is marinated in marinade, then taken out, air-dried, sterilized, and vacuum-packed. The composition of marinade of the present invention is 5kg of star anise, 3kg of cinnamon, 3kg of cumin, 2kg of ...

Embodiment 2

[0024] Slaughter and clean the goose; cover the surface of the goose carcass with a mixture of fragrant leaves, peppercorns, and star anise that are ground into powder and then fried with salt; inject marinade evenly into the goose body, and put the goose into a vacuum tumbler after injection Low temperature, pickling by intermittent cycle vacuum mode; the mass ratio of goose meat and pickling liquid in the vacuum tumbler is 10:4. Multiple cycles are adopted at a low temperature of 1°C. In each cycle, the air in the tumbler is first pumped out to a vacuum of 80 kPa, and kept for 2 hours, and then the atmospheric pressure is restored, and kept for 3 hours. The vacuum tumbler uses a speed of 5 r / min for tumbling, and stops for 0.5h every 15 minutes of tumbling. The processed goose is marinated in marinade, then taken out, air-dried, sterilized, and vacuum-packed. The composition of marinade of the present invention is 8kg of star anise, 5kg of cinnamon, 5kg of cumin, 5kg of lic...

Embodiment 3

[0026] Slaughter and clean the goose; cover the surface of the goose carcass with a mixture of fragrant leaves, peppercorns, and star anise that are ground into powder and then fried with salt; inject marinade evenly into the goose body, and put the goose into a vacuum tumbler after injection Low temperature, pickling by intermittent cycle vacuum mode; the mass ratio of goose meat and pickling liquid in the vacuum tumbler is 10:5. Multiple cycles are adopted at a low temperature of 2°C. In each cycle, the air in the tumbler is first pumped out to a vacuum of 90 kPa, and kept for 3 hours, and then the atmospheric pressure is restored, and kept for 3 hours. The vacuum tumbler adopts a speed of 5r / min for tumbling, and stops for 0.5h every 15 minutes of tumbling. The processed goose is marinated in marinade, then taken out, air-dried, sterilized, and vacuum-packed. The composition of marinade of the present invention is star anise 6kg, cinnamon bark 4kg, cumin 4kg, licorice 4kg,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com