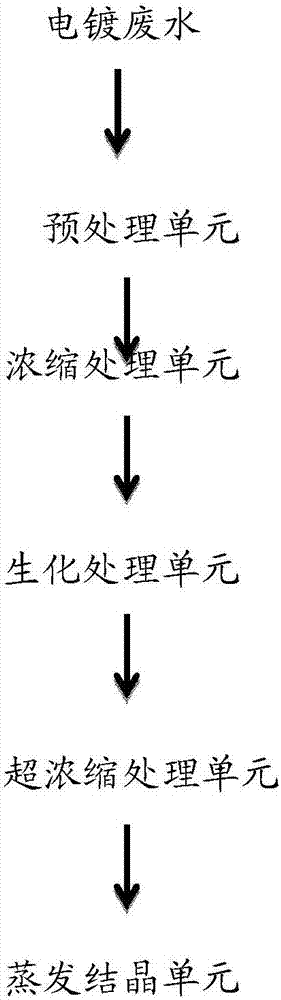

Electroplating wastewater treatment method, treatment system and application

A treatment method and technology for electroplating wastewater, applied in metallurgical wastewater treatment, multi-stage water treatment, water/sewage treatment, etc., can solve the problems of large amount of resin, large power consumption, secondary pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0240] (1) electroplating waste water of the present invention is carried out pretreatment, obtains pretreatment water

[0241] The metal electroplating wastewater pretreatment process of the present invention: introduce metal wastewater into the network-breaking tank, add sulfuric acid with a concentration of 10% in the network-breaking tank until the pH is 2-3; then introduce the wastewater into the pH-adjusting tank, and add the sulfuric acid at a concentration of 10% % sodium hydroxide to adjust the pH to 9-10; introduce the treated wastewater into the chemical reaction tank, add FeCl 3 , then add PAM, and stir for 20-30min; finally, the treated wastewater is introduced into a precision-controlled high-efficiency sedimentation system; the precision-controlled high-efficiency sedimentation system is composed of a water distribution system, a sedimentation treatment tank, an inclined pipe, an outlet weir, and a sludge hopper. ; It can efficiently remove the floc precipitatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com