Electroosmosis electrode and mounting mode

An installation method and electrode technology, applied in soil protection, construction, infrastructure engineering, etc., can solve the problems of low electroosmosis efficiency, high contact resistance, and difficult penetration of electrodes, so as to improve electroosmosis efficiency and reduce resistance , Improve the effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

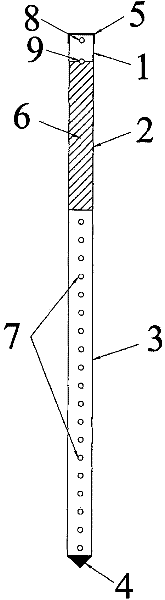

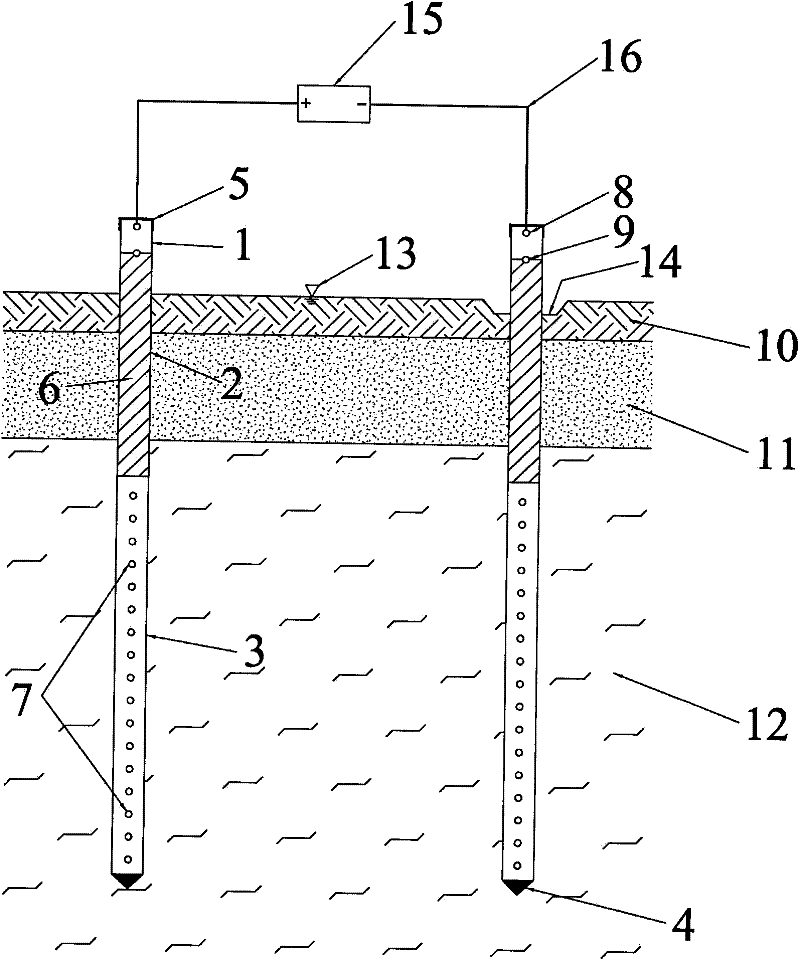

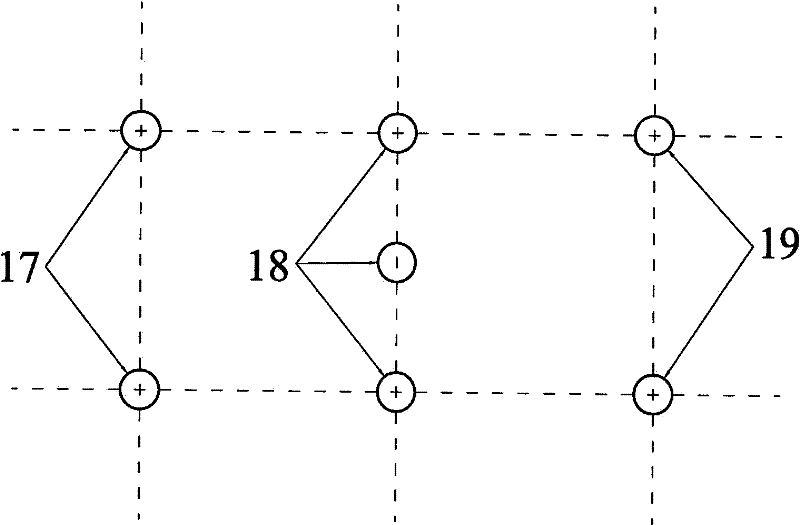

[0028] Such as figure 1 As shown, the electroosmotic electrode of the present invention is sequentially divided into connecting exhaust section 1, insulating section 2 and opening treatment section 3 on the same metal pipe from top to bottom; there are 4 small holes on connecting exhaust section 1, which are in The upper wire connection hole 8 is connected to the wires in the circuit, and the drainage vent hole 9 in the lower part is used for drainage and exhaust; the function of the drainage hole 7 is to allow the water collected near the cathode due to electroosmosis to enter the electrode and then be discharged. To facilitate the discharge of water, the drainage vent 9 should be as close to the ground as possible; the outer side of the insulating section 2 is coated with insulating paint 6; the opening treatment section 9 is densely covered with drai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com