Advanced treatment process for paper-making waste water

A papermaking wastewater and advanced treatment technology, applied in the field of decolorization process, can solve the problems of insufficient decolorization, high power consumption, and high cost, and achieve the effects of saving operating costs, good conductivity, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

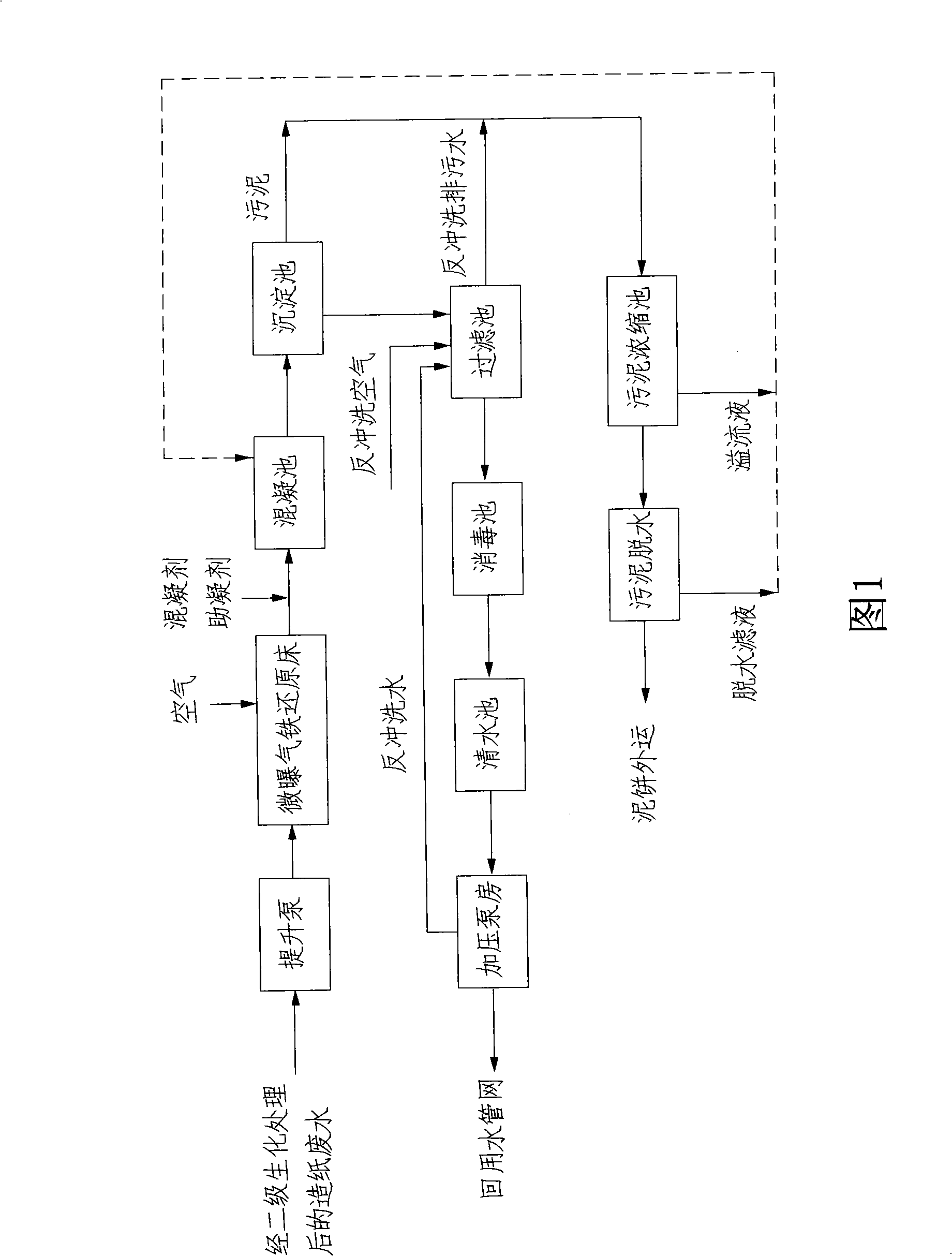

[0021] A papermaking wastewater advanced treatment process, the process comprises the following steps:

[0022] ①Introduce the papermaking wastewater after the secondary biochemical treatment into the micro-aeration iron reduction bed, fill the iron filings in the micro-aeration iron reduction bed, and carry out the reduction reaction in the micro-aeration iron reduction bed for the papermaking wastewater;

[0023] ②Introduce the effluent treated in step ① into the coagulation tank, and add coagulant and coagulant aid in the coagulation tank to promote the aggregation of particles in the water;

[0024] ③Introduce the effluent treated in step ② into the sedimentation tank for mud-water separation;

[0025] ④The effluent from the sedimentation tank is introduced into the filter tank for filtration, and the filtered effluent is sterilized and then introduced into the reuse water pipe network;

[0026] ⑤The sludge in the sedimentation tank and the backwash sewage in the filter t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com