Efficient and stable coking wastewater advanced treatment process and treatment system

A technology for coking wastewater and advanced treatment, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc. Salt system and process issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

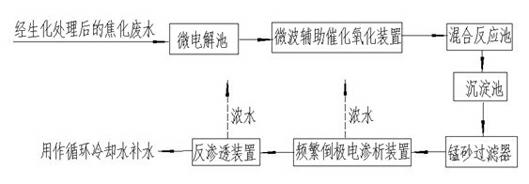

[0060] The coking wastewater advanced treatment system described in this embodiment is as follows: figure 1 shown, including:

[0061] micro electrolytic cell;

[0062] A microwave-assisted catalytic oxidation device connected with the micro-electrolytic cell;

[0063] A mixing reaction tank connected to the microwave-assisted catalytic oxidation device, and a sedimentation tank connected to the mixing reaction tank;

[0064] The filter that is connected with described settling tank, the filter that uses in the present embodiment is manganese sand filter;

[0065]A frequent electrode reversal electrodialysis device connected with the manganese sand filter;

[0066] The coking wastewater advanced treatment system also includes a reverse osmosis device connected to the fresh water outlet of the frequent electrode reversal electrodialysis device.

[0067] The treatment process of the coking wastewater advanced treatment system described in this embodiment is:

[0068] (1) Co...

Embodiment 2

[0075] The coking wastewater advanced treatment system described in this embodiment is the same as that in Embodiment 1.

[0076] The treatment process of the coking wastewater advanced treatment system described in this embodiment is:

[0077] (1) Coking wastewater after A / O biochemical treatment, with a volume of 1200m 3 The water inflow of / d enters the micro-electrolytic cell, adds acid to the coking wastewater in the micro-electrolytic cell to adjust the pH value of the coking wastewater to 4.0, and aerates the coking wastewater, and the air-to-water ratio is 8: 1, the contact time of the coking wastewater and the iron-carbon filler in the micro-electrolytic cell is 1h;

[0078] (2) The effluent after the electrolytic treatment of the micro-electrolytic cell enters the microwave-assisted catalytic oxidation device, and the ferrous salt and hydrogen peroxide are added to the coking wastewater in the microwave-assisted catalytic oxidation device and stirred evenly. Cataly...

Embodiment 3

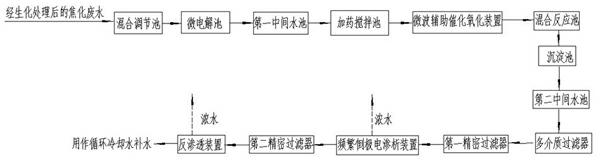

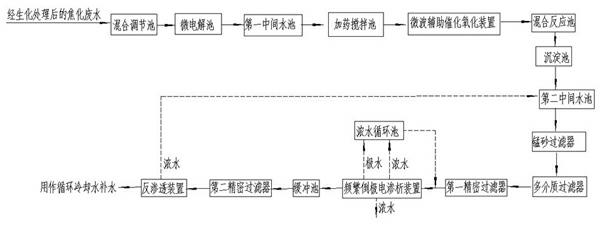

[0084] The coking wastewater advanced treatment system described in this embodiment is as follows: figure 2 shown, including:

[0085] A mixing regulating pool, a micro electrolytic cell is connected to the mixing regulating pool, a first intermediate water pool is connected to the micro electrolytic cell, and a dosing stirring pool is connected to the first intermediate water pool, and the mixing regulating pool is connected to the mixing regulating pool. The above-mentioned dosing stirring tank is connected with a microwave-assisted catalytic oxidation device;

[0086] A mixing reaction tank connected to the microwave-assisted catalytic oxidation device, and a sedimentation tank connected to the mixing reaction tank, a second intermediate water tank connected to the sedimentation tank, the second intermediate water tank is provided with aeration device;

[0087] A multimedia filter connected to the second intermediate pool, and a first precision filter connected to the mu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com