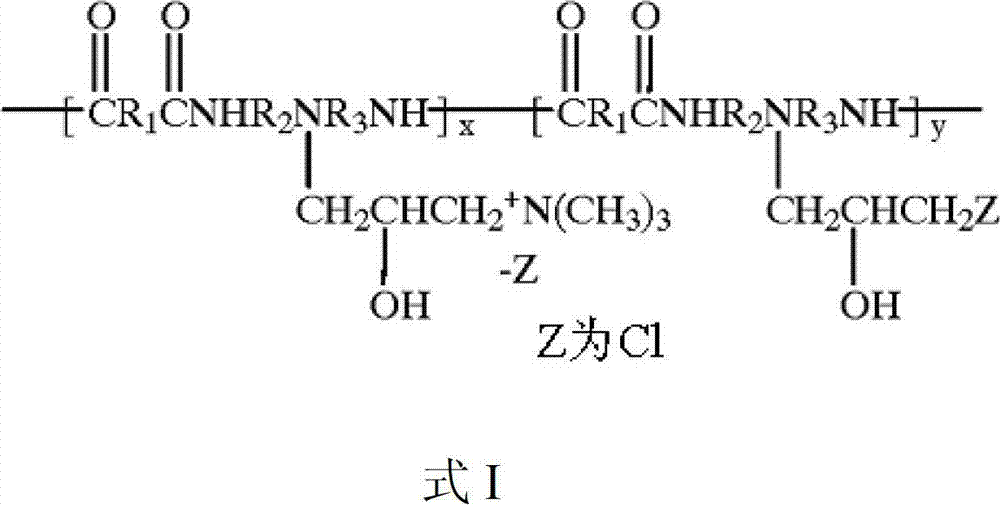

High-solid content polyamide polyamine epichlorohydrin wet strength agent, as well as preparation and application thereof

A technology of polyamide polyamine epichlorohydrin and polyamide polyamine, which is applied in the direction of reinforcing agent addition, paper, textiles and papermaking, etc. It can solve the problems of no evaluation of wet strength performance, long preparation time, complicated preparation process, etc. , to achieve the effects of good stability, high efficiency, and less chlorine-containing by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

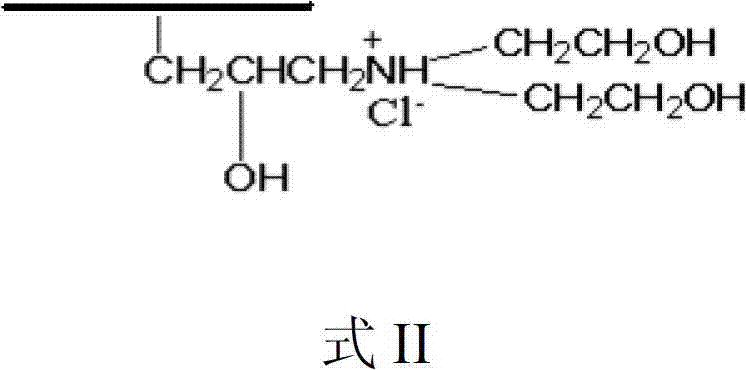

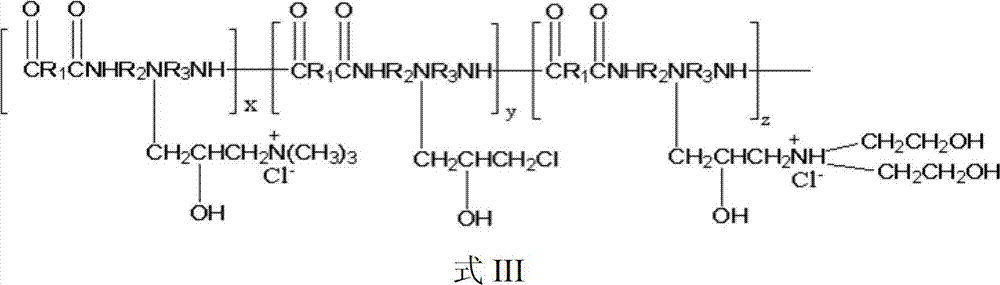

Method used

Image

Examples

Embodiment 1

[0046] (1) Add 0.5mol adipic acid into a 1000mL three-necked flask, fix the three-necked flask on a controllable electric heating mantle, heat up to 100°C, add 0.55mol diethylenetriamine, and after the material is completely dissolved, add dodecylbenzene 0.005mol of sulfonic acid, the temperature was raised to 160°C, and the reaction was carried out for 12h. The viscosity of the material is very large. After the reaction, when the temperature drops below 120 °C, add distilled water with the same quality as the product, stir evenly, and obtain a polyamide polyamine intermediate with a solid content of 50% (mass percentage), which is measured with a Brookfield IIplus viscometer. Its viscosity is 415mpa.s.

[0047] (2) Add 0.5mol polyamide polyamine intermediate solution with a solid content of 50% (mass percentage) into a 1000mL three-necked flask, place the three-necked flask in a water bath on a magnetic heater, stir, and control the reaction temperature to be 20°C, 0.35mol o...

Embodiment 2

[0050] (1) 0.5mol of terephthalic acid was added to a 1000mL three-necked bottle, the three-necked bottle was fixed on a controllable electric heating mantle, the temperature was raised to 100°C, 0.505mol of triethylenetetramine was added, and after the material was completely dissolved, dodecane was added 0.0005mol of benzenesulfonic acid, the temperature was raised to 160°C, and the reaction was carried out for 10h. The viscosity of the material is very large. After the reaction, when the temperature drops below 120 °C, add distilled water equal to the product quality, stir evenly, and obtain a polyamide polyamine intermediate with a solid content of 50% (mass percentage), which is measured with a Brookfield IIplus viscometer. The viscosity is 380mpa.s.

[0051] (2) Add 0.5mol polyamide polyamine intermediate solution with a solid content of 50% (mass percentage) into a 1000ml three-necked flask, place the three-necked flask in a water bath on a magnetic heater, stir, and co...

Embodiment 3

[0054] (1) 0.5mol terephthalic acid was added to a 1000mL three-necked bottle, the three-necked bottle was fixed on a controllable electric heating mantle, slowly heated to 100°C, 0.2mol propylenediamine and 0.305mol triethylenetetramine were added, and the material was completely After dissolving, 0.0005mol of dodecylbenzenesulfonic acid was added, the temperature was raised to 160°C, and the reaction was carried out for 10h. The viscosity of the material is very large. After the reaction, when the temperature drops below 120 °C, add distilled water with the same quality as the product, stir evenly, and obtain a polyamide polyamine intermediate with a solid content of 50% (mass percentage), which is measured with a Brookfield IIplus viscometer. Its viscosity is 412mpa.s.

[0055] (2) 0.5mol polyamide polyamine intermediate solution with a solid content of 50% (mass percentage) was added to a 1000mL three-necked flask, and the three-necked flask was placed in a water bath on a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com