Combined-type hydrogenation treatment method of tire pyrolysis oil

A tire pyrolysis oil and hydrogenation treatment technology, which is applied in the fields of hydrogenation treatment process, hydrocarbon oil treatment, petroleum industry, etc., and can solve the problems of equipment investment increase and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

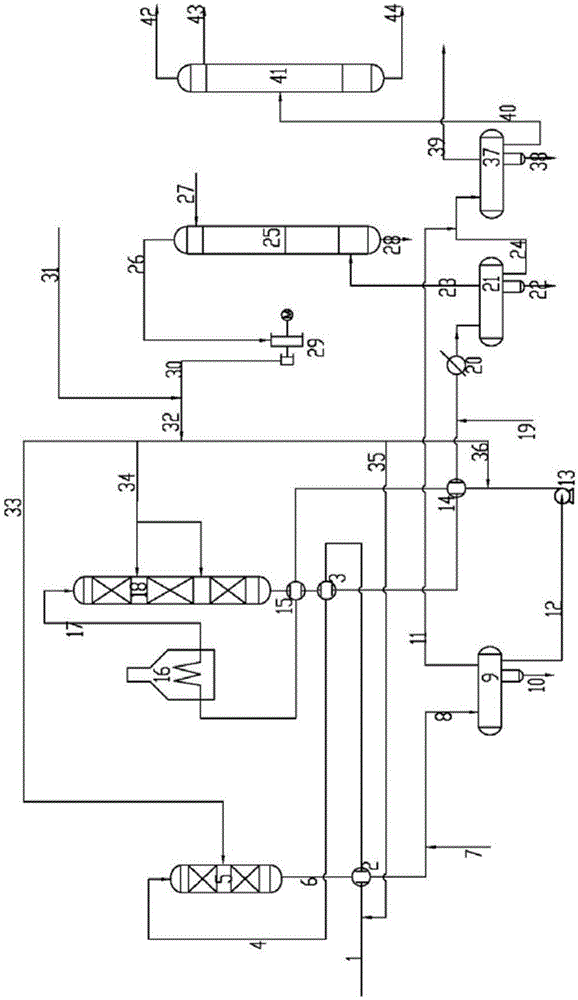

Method used

Image

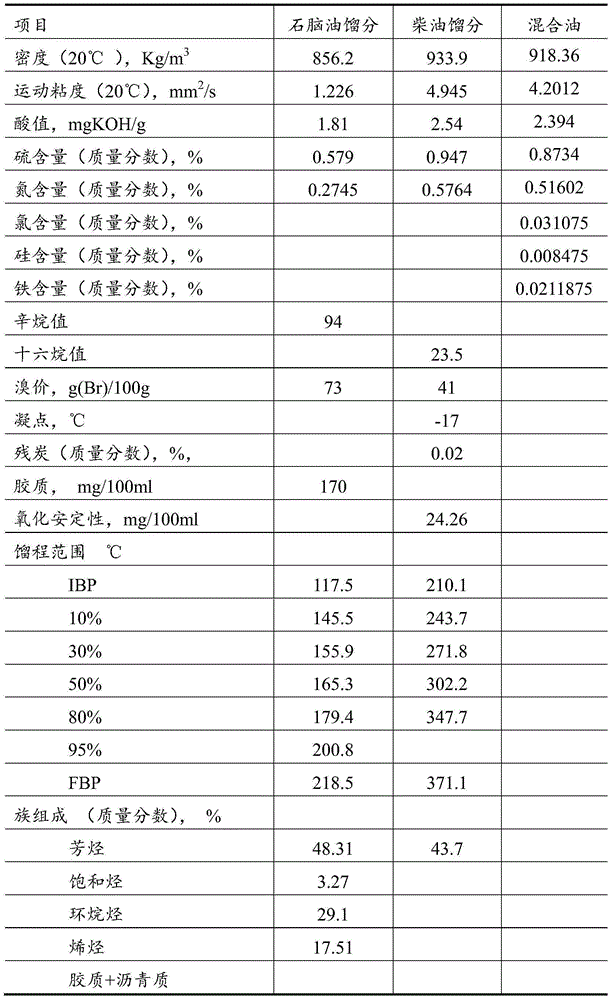

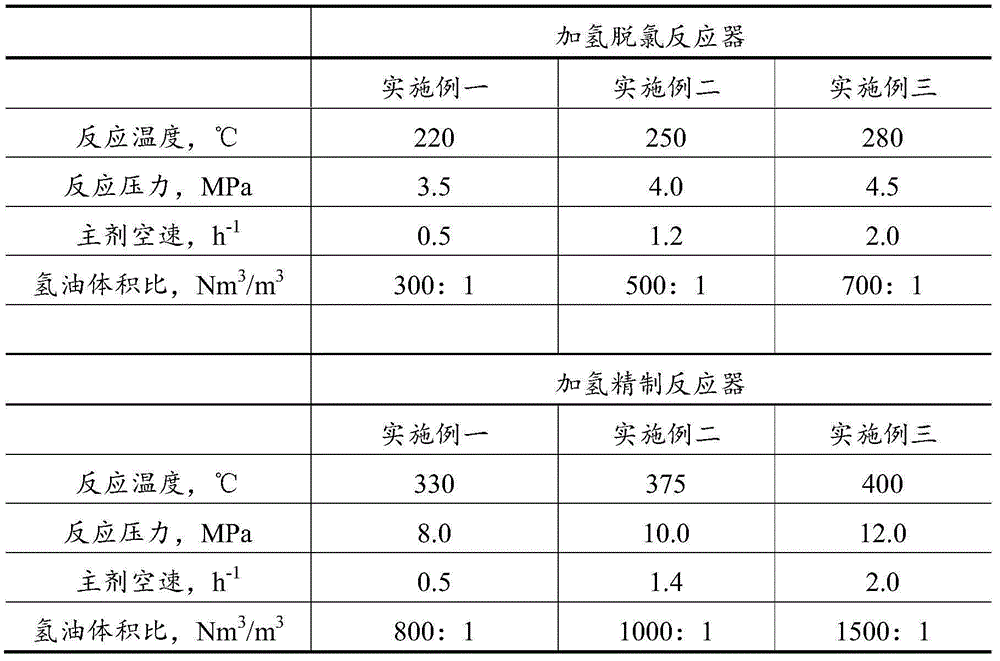

Examples

preparation example Construction

[0064] A more detailed preparation method of the hydrodechlorination catalyst is described in the above-mentioned Chinese patent, which is hereby cited as a part of the content of the present invention.

[0065] In step (b), after dechlorination, the ammonia molar equivalent of injecting ammonia water is not less than 1.02 times of the hydrogen chloride molar weight, and the maximum is not more than 1.1 times. The operating temperature of the low score is 100-180°C, and the operating pressure is 3.0-4.0MPa.

[0066] In step (c), after the hydrofinishing feed is mixed with the mixed hydrogen, it exchanges heat with the hydrofinishing reaction product, fully utilizes the heat energy of the refined reaction product, reduces the load of the heating furnace and fuel gas consumption, and saves investment and operation cost.

[0067] In step (c), the hydrofinishing reactor is sequentially filled with a protective agent, a demetallizing agent, and a hydrofinishing agent according to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com