System and method for purifying tail gas of medical waste incineration

A technology for exhaust gas purification and medical waste, applied in the field of flue gas purification, can solve the problem of low utilization rate of absorbent, and achieve the effect of improving purification efficiency and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

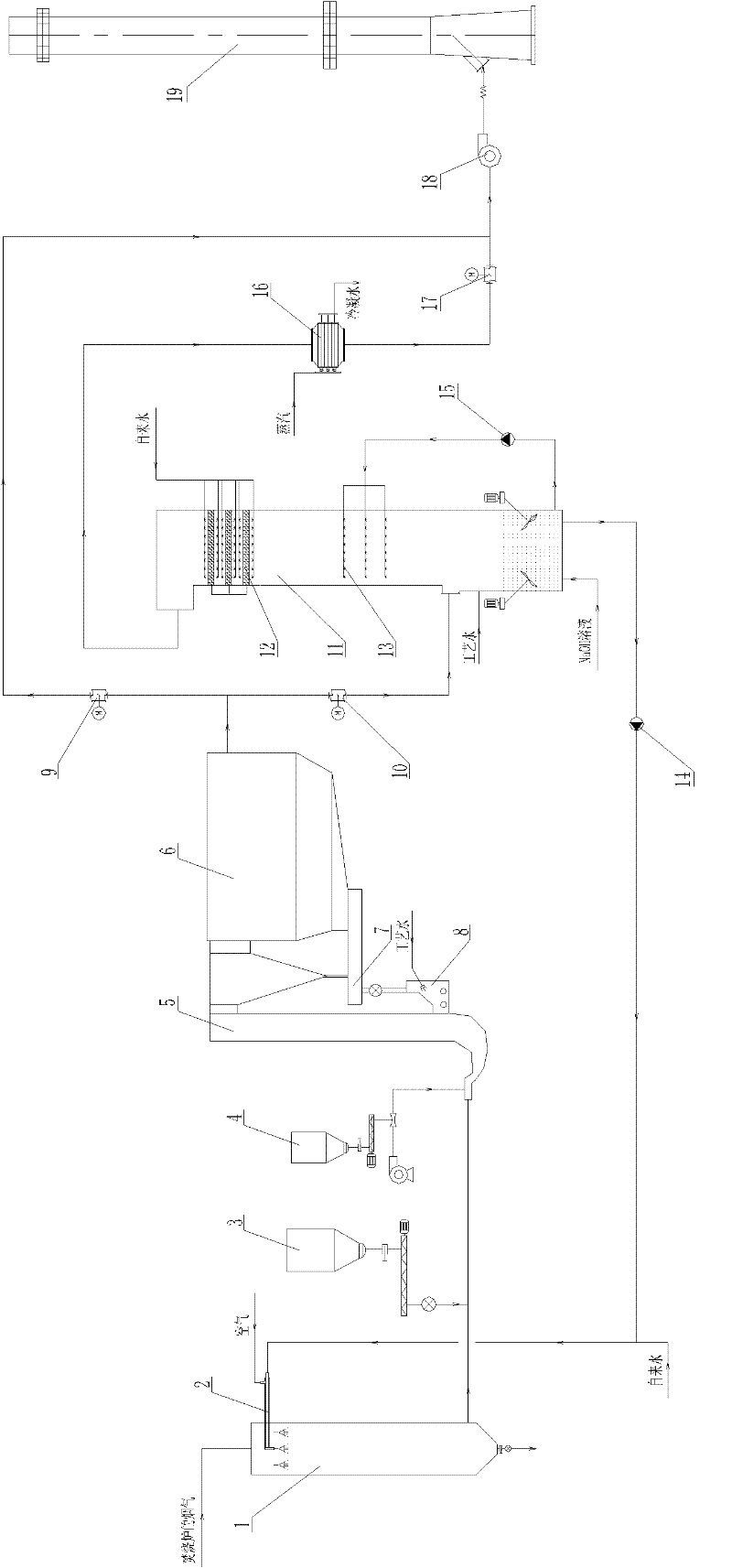

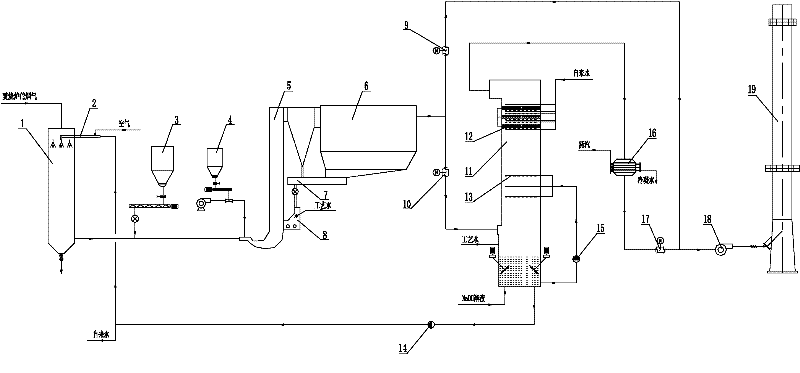

[0017] Such as figure 1 As shown, the medical waste incineration exhaust gas purification system includes a flue gas quenching tower 1, a semi-dry reactor 5, a bag filter 6, a spray absorption tower 11, a steam-flue gas heat exchanger 16, and an induced draft fan 18 connected in series. and a chimney 19, the flue gas quenching tower 1 is provided with a spray gun 2, a lime feeding system 3 and an activated carbon feeding system 4 are provided between the flue gas quenching tower 1 and the semi-dry reactor 5, and the spray absorption tower 11 is equipped with There is a demister 12 and a spray layer 13, an inlet baffle 10 is provided between the bag filter 6 and the spray absorption tower 11, an outlet baffle is provided between the steam-flue gas heat exchanger 16 and the induced draft fan 18 Plate 17, a bypass baffle 9 is provided between the bag filter 6 and the induced draft fan 18, a fluidization tank 7 is provided at the dust outlet of the bag filter 6, and the outlet of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com