Adsorbent for removing organic chlorides in hydrocarbon-containing substance flow and preparation method thereof

A technology for organic chloride and hydrocarbon streams, which is applied in chemical instruments and methods, refined hydrocarbon oil, and other chemical processes, and can solve the problems of low dynamic adsorption rate, short service life, and limited adsorption capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

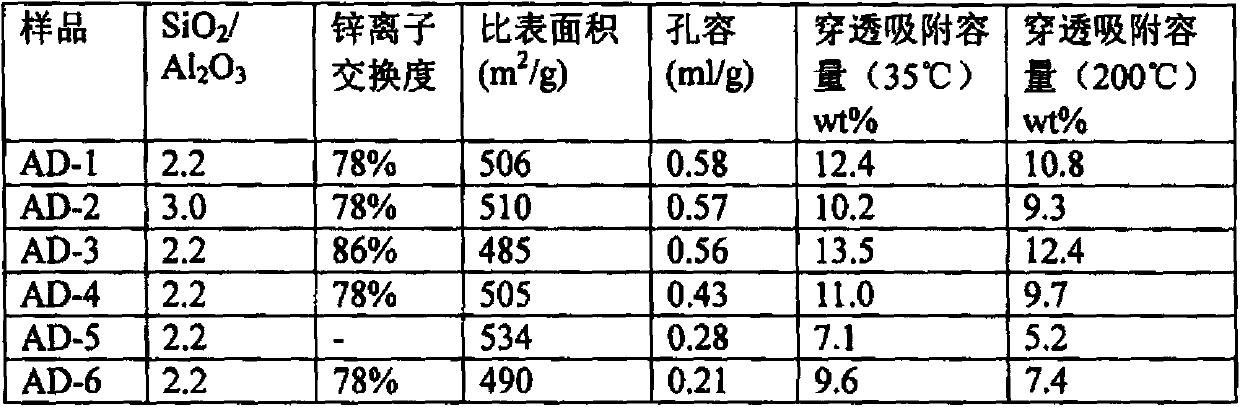

[0024] Take the ratio of silicon to aluminum (SiO 2 / Al 2 o 3 ) is 2.2 NaKLSX former powder 100g and 1500ml concentration is the ZnCl of 0.8mol / l 2 The solution was mixed evenly, then placed in a small exchange tank at 50°C, exchanged under stirring for 1 hour, filtered and washed with suction. The resulting sample was redissolved in 1500 ml of the above ZnCl 2 The solution was exchanged for the second time, suction filtered and washed again, and the obtained sample was dried in an oven at 90° C. for 3 hours to obtain a modified zeolite molecular sieve with a zinc ion exchange degree of 78%. Weigh 70g of the above-mentioned modified zeolite molecular sieve, 15g of diatomaceous earth, and 15g of attapulgite, mix them evenly, and put them into a small rotating disk. During the rotation, stir the mixed powder with a spatula, and slowly add water to form particles. , a total of 18.5 g of moisture was added before the microparticles began to stick together to form the specified...

Embodiment 2

[0026] Use the method that embodiment 1 proposes to prepare adsorbent, but change NaKLSX former powder into silicon-aluminum ratio (SiO 2 / Al 2 o 3 ) is the 13X original powder of 3.0, and the rest of the steps are the same, and the sample AD-2 is prepared, and the performance results of the sample are listed in Table 1.

Embodiment 3

[0028] Take the ratio of silicon to aluminum (SiO 2 / Al 2 o 3 ) is 2.2 NaKLSX former powder 100g and 1500ml concentration is the ZnCl of 1.0mol / l 2 The solution was mixed evenly, then placed in a small exchange tank at 60°C, exchanged under stirring for 1 hour, filtered and washed with suction. The resulting sample was redissolved in 1500 ml of the above ZnCl 2 The solution was exchanged for the second time, suction filtered and washed again, and the obtained sample was dried in an oven at 90° C. for 3 hours to obtain a modified zeolite molecular sieve with a zinc ion exchange degree of 86%. The rest of the molding steps were the same as in Example 1, and the sample AD-3 was prepared, and the performance results of the sample are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com