Additive for removing organochlorine from crude oil and removal technology thereof

An additive and organochlorine technology, applied in the field of oil refining process additives, can solve the problems of catalyst poisoning, atmospheric and vacuum tower damage, FCC catalyst damage, etc., and achieve the effects of reducing corrosion and reducing chloride ion content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

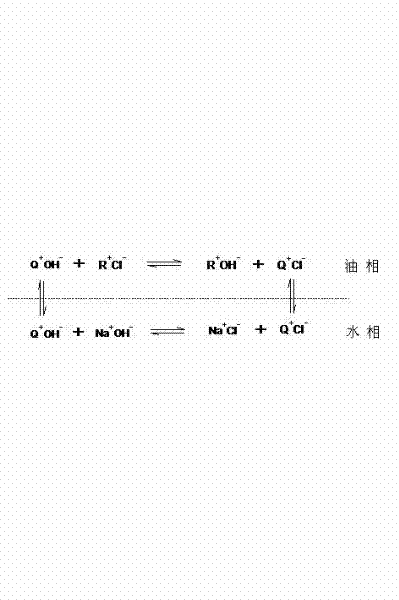

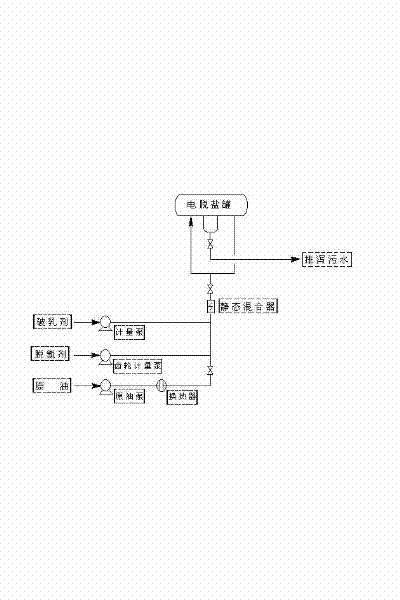

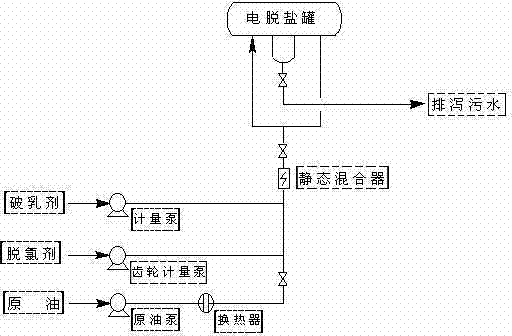

[0033] detailed description: The present invention will be further explained below in conjunction with the drawings:

[0034] The present invention will be described in detail below in conjunction with embodiments, but the protection scope of the present invention is not limited to the following embodiments.

[0035] The invention provides an additive for removing organic chlorine in crude oil. The additive is prepared by compounding a phase transfer catalyst, an alkali and a solvent in the following proportions: the mass percentage of the phase transfer catalyst is 2%-10%, and the mass percentage of the alkali It is 10%-30%, and the mass percentage of solvent is 60-88%.

[0036] The phase transfer catalyst is a quaternary ammonium base or polyethylene glycol; the base is sodium hydroxide, sodium ethoxide or ethanolamine; the solvent is one of the following three situations: a mixture of water and ethanol, a mixture of water and methanol, water, ethanol , A mixture of methanol.

[...

Embodiment 1

[0046] Example 1. According to the mass ratio of 3% N,N-dimethyl-octadecyl-benzyl ammonium hydroxide, 20% sodium hydroxide, 42% water and 35% ethanol are mixed to prepare crude oil. Chlorine.

Embodiment 2

[0047] Example 2. A crude oil dechlorination agent was prepared by mixing 4% triethylbenzylammonium hydroxide, 15% sodium ethoxide, 46% water and 35% ethanol by mass ratio.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com