Photocatalytic metal dissolution method

A photocatalysis and photocatalyst technology, applied in the field of photocatalysis, can solve the problems of strong chlorine toxicity, cumbersome steps, environmental hazards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Disperse 500mg of a material containing 1% platinum into a mixed solution of 50ml of acetonitrile and dichloromethane (50:1), then add 50mg of a commercially available mixed-phase titanium dioxide catalyst, and irradiate it with ultraviolet light for 4 hours in the air, and the dissolution rate of platinum is 81.6%. .

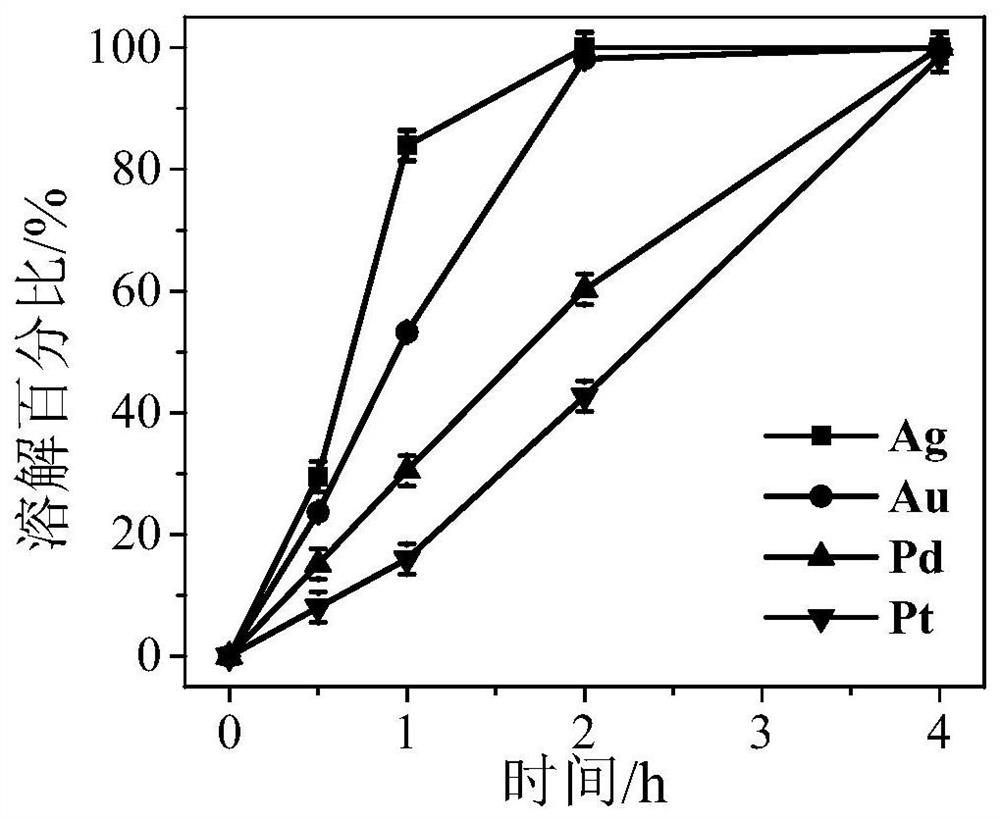

[0028] figure 1 , 2 Divided into sample diagrams before and after the dissolution reaction, from figure 1 It can be seen that the sample is gray-black before dissolution; figure 2 It can be seen that the sample turns white after the dissolution reaction; image 3 It can also be clearly seen from the ICP test data in the liquid that the proportion of platinum in the liquid is continuously increasing (take a small amount of solution to evaporate the solvent and add water with the same amount of solvent to dilute it for detection).

Embodiment 2

[0030] Disperse 500mg of a material containing 1% platinum into a mixed solution of 100ml of acetonitrile and dichloromethane (50:1), then add 50mg of a commercially available mixed-phase titanium dioxide catalyst, and irradiate it with ultraviolet light for 4 hours in the air. The dissolution rate of platinum is 91.4%. .

Embodiment 3

[0032] Disperse 500 mg of a material containing 1% platinum into a mixed solution of 200 ml of acetonitrile and dichloromethane (50:1), then add 50 mg of a commercially available mixed-phase titanium dioxide catalyst, and irradiate with ultraviolet light in air for 4 hours, and the dissolution rate of platinum is 100%. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com