Method for preparing alligatored surface of light-emitting diode by using PS spheres as template

A technology for light-emitting diodes and roughened surfaces, which can be used in semiconductor devices, electrical components, circuits, etc., and can solve problems such as poor tolerance of photoresist, difficulty in developing, photolithographic patterns and large wavelengths, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

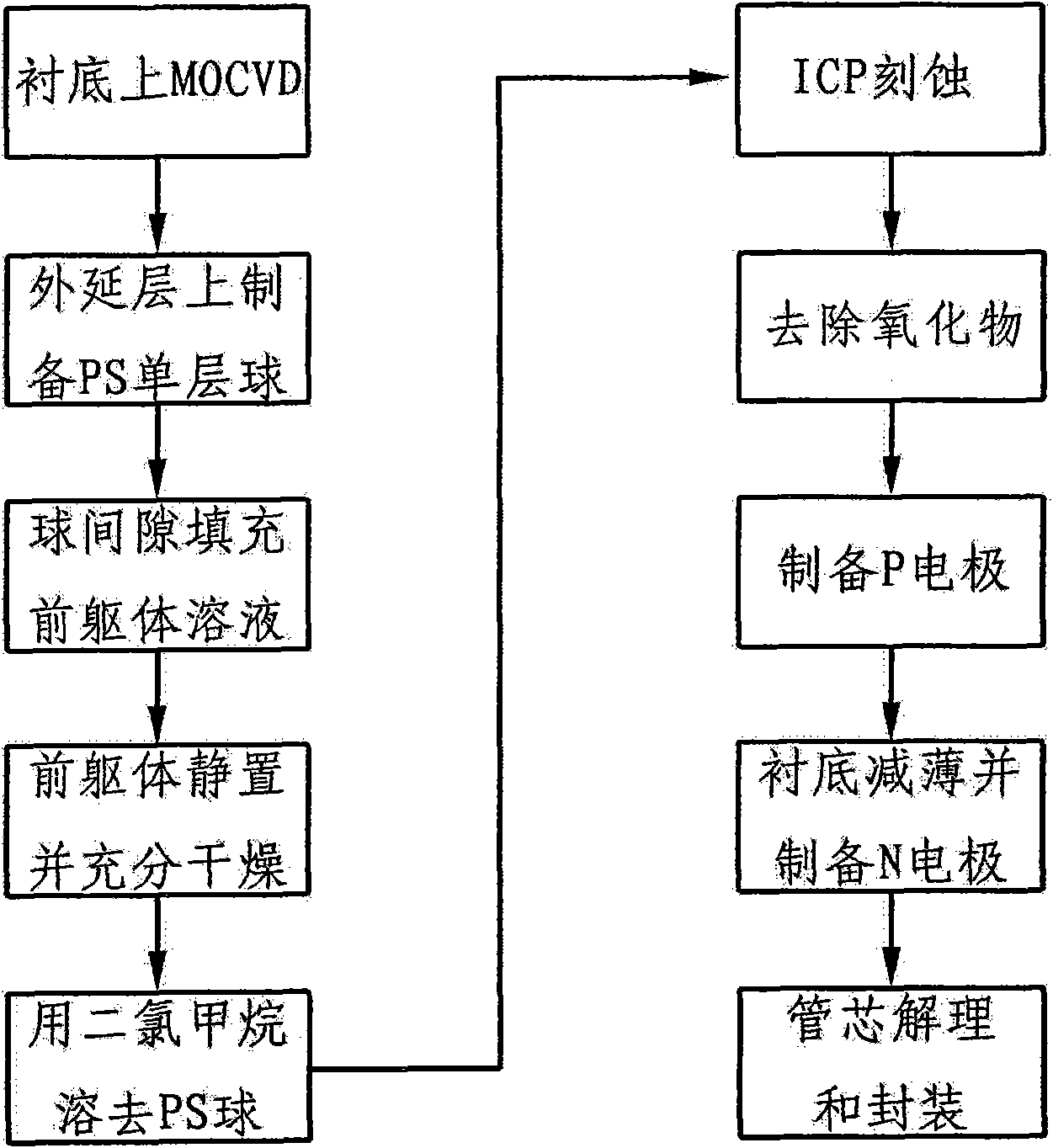

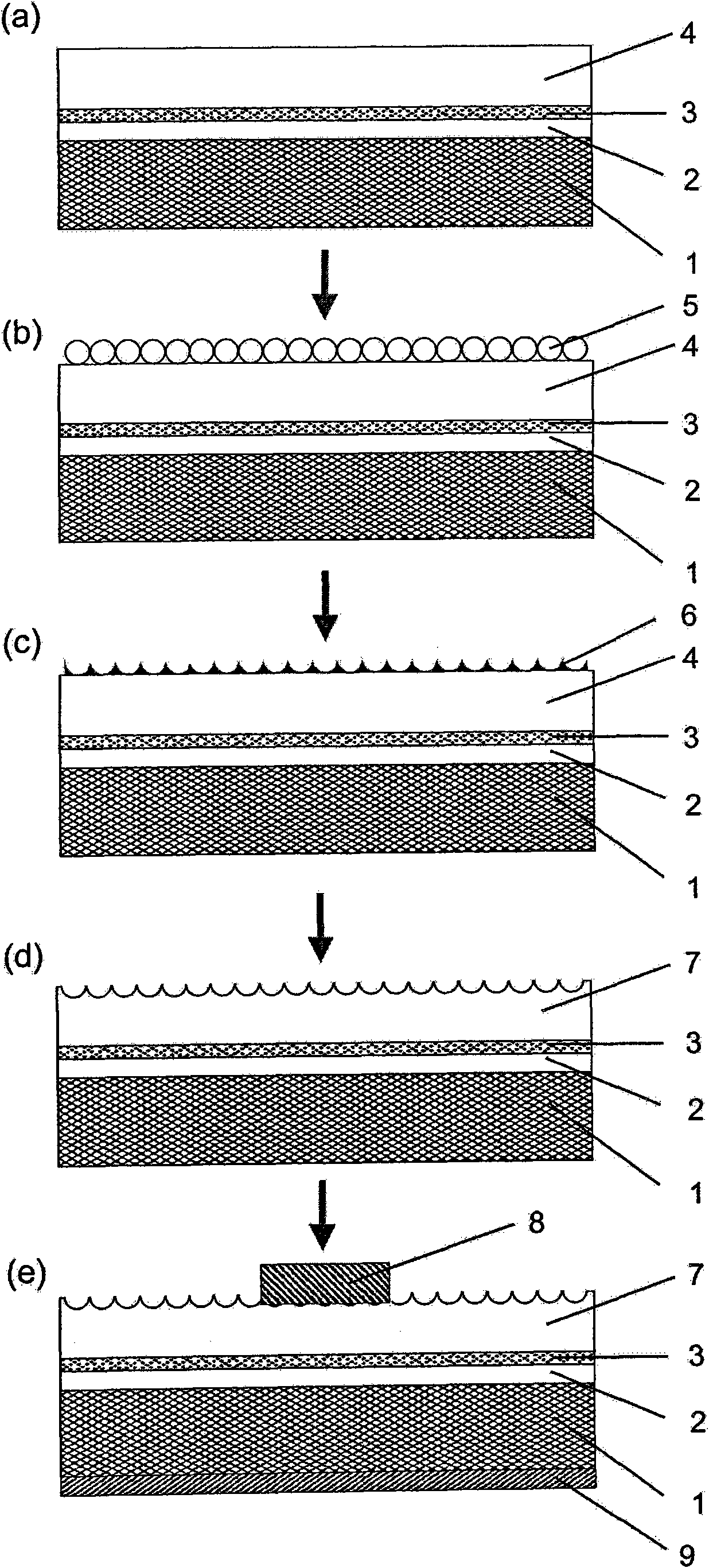

[0022] Such as figure 1 and figure 2 As shown in the flow chart of the operation steps of the present invention and the illustrations, the method of the present invention using PS balls as a template to make a rough surface of a light-emitting diode specifically includes the following steps:

[0023] (1) First, the N-type contact layer 2, the multi-quantum well active region 3 and the P-type contact layer 4 are epitaxially grown on the substrate 1 by metal-organic chemical vapor deposition according to the conventional LED epitaxial growth method to form an epitaxial wafer. Among them, the substrates of red and yellow LEDs are GaAs materials, and the substrates of blue LEDs are Si, GaN or SiC materials. The substrate 1 in this embodiment is a GaAs substrate. see figure 2 Figure (a) in.

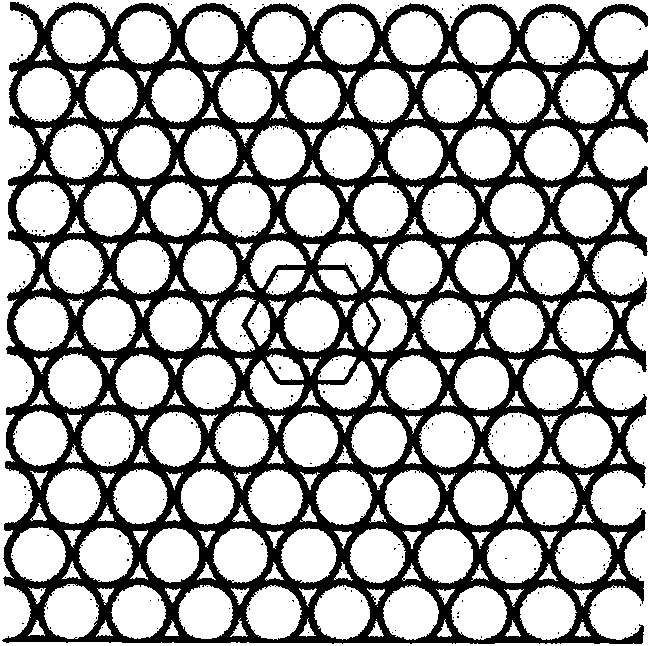

[0024] (2) On the P-type contact layer 4 of epitaxial growth, lay a layer of monolayer film that is formed by the close arrangement of PS balls, the diameter of PS balls is 1000nm in the...

Embodiment 2

[0031] The difference between this example and Example 1 is that in step (4), tin chloride is used as a precursor, tin chloride, ethanol and water are mixed in a mass ratio of 1:4:20 and then filled in the PS ball sheet In the gap between the ball of the layer film 5 and the P-type contact layer 4, let the ethanol and water evaporate at room temperature for 72 hours, and place the epitaxial wafer after standing in a drying oven at 500°C for 1 hour to make the chlorine The tin oxide decomposes into tin oxide. Then obtain the periodic bowl-shaped structure of tin oxide in the same way as in Example 1 step (4), etch the P-type contact covered by the bowl-shaped periodic structure of tin oxide in the same way as in Example 1 step (5). Layer 4, finally adopt HF, NH 3 The corrosive liquid mixed with F and water corrodes the residual tin oxide to obtain a periodic structure of the roughened P-type contact layer.

Embodiment 3

[0033]This embodiment is the same as that of Example 1. In step (3), aluminum nitrate is used as the precursor, and aluminum nitrate, ethanol and water are mixed according to the mass ratio of 1:4:20, and then filled in the PS ball sheet. In the gap between the ball of the layer film 5 and the P-type contact layer 4, let the ethanol and water evaporate at room temperature for 72 hours, place the epitaxial wafer after standing in a drying oven at 500°C for 1 hour, and let the nitric acid Aluminum breaks down to alumina. Then obtain the periodically arranged bowl-shaped structure of aluminum oxide by the same method of embodiment 1 step (4), etch the P-type contact covered by the bowl-shaped periodic arrangement structure of tin oxide by the same method of embodiment 1 step (5) Layer 4, finally adopt HF, NH 3 The corrosive solution mixed with F and water corrodes the residual aluminum oxide to obtain a periodic structure of the coarsened P-type contact layer.

[0034] Chloride...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com