Method for extracting valuable metals from laterite nickel mine with hydrochloric acid full-closed circulation method

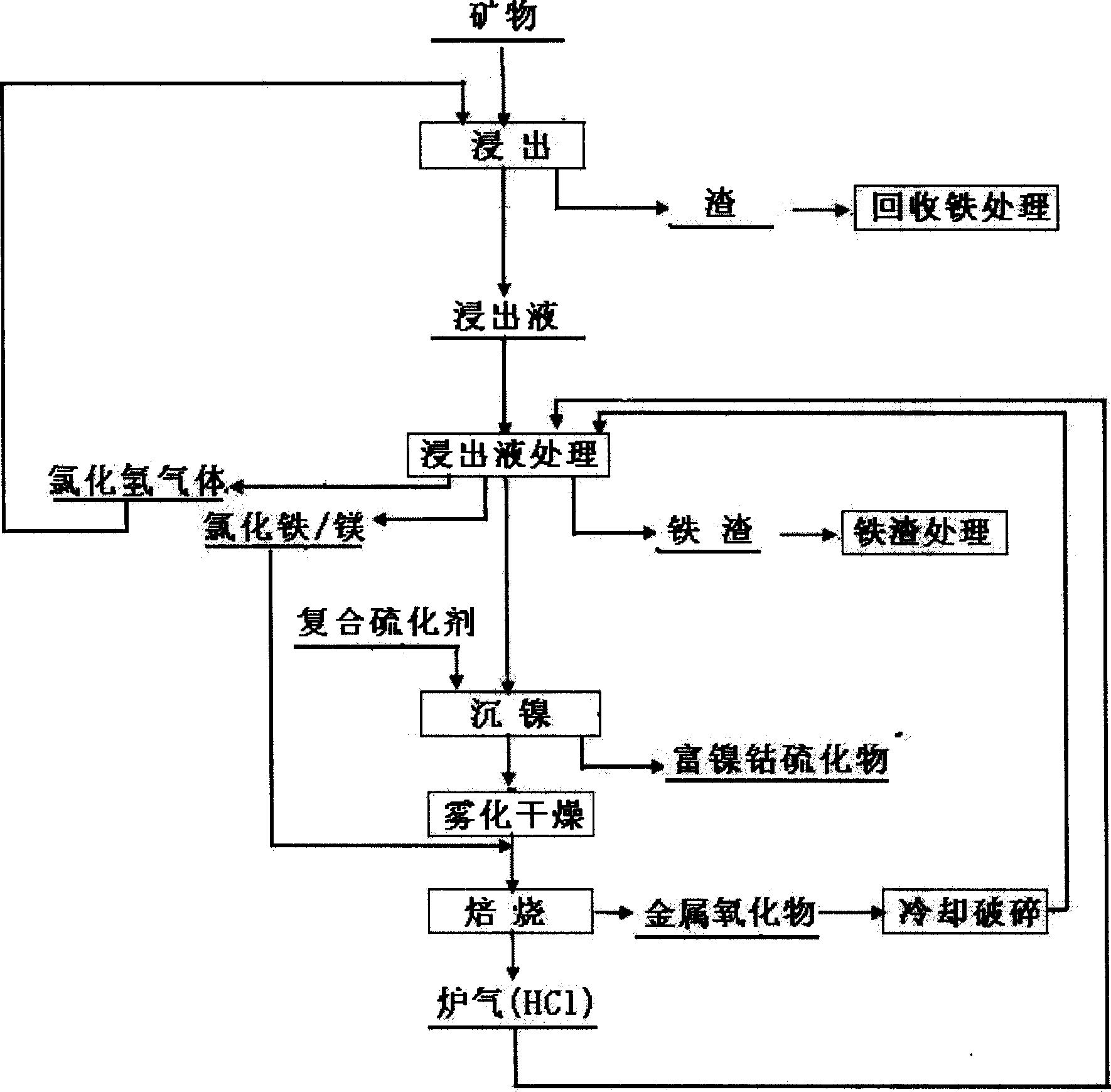

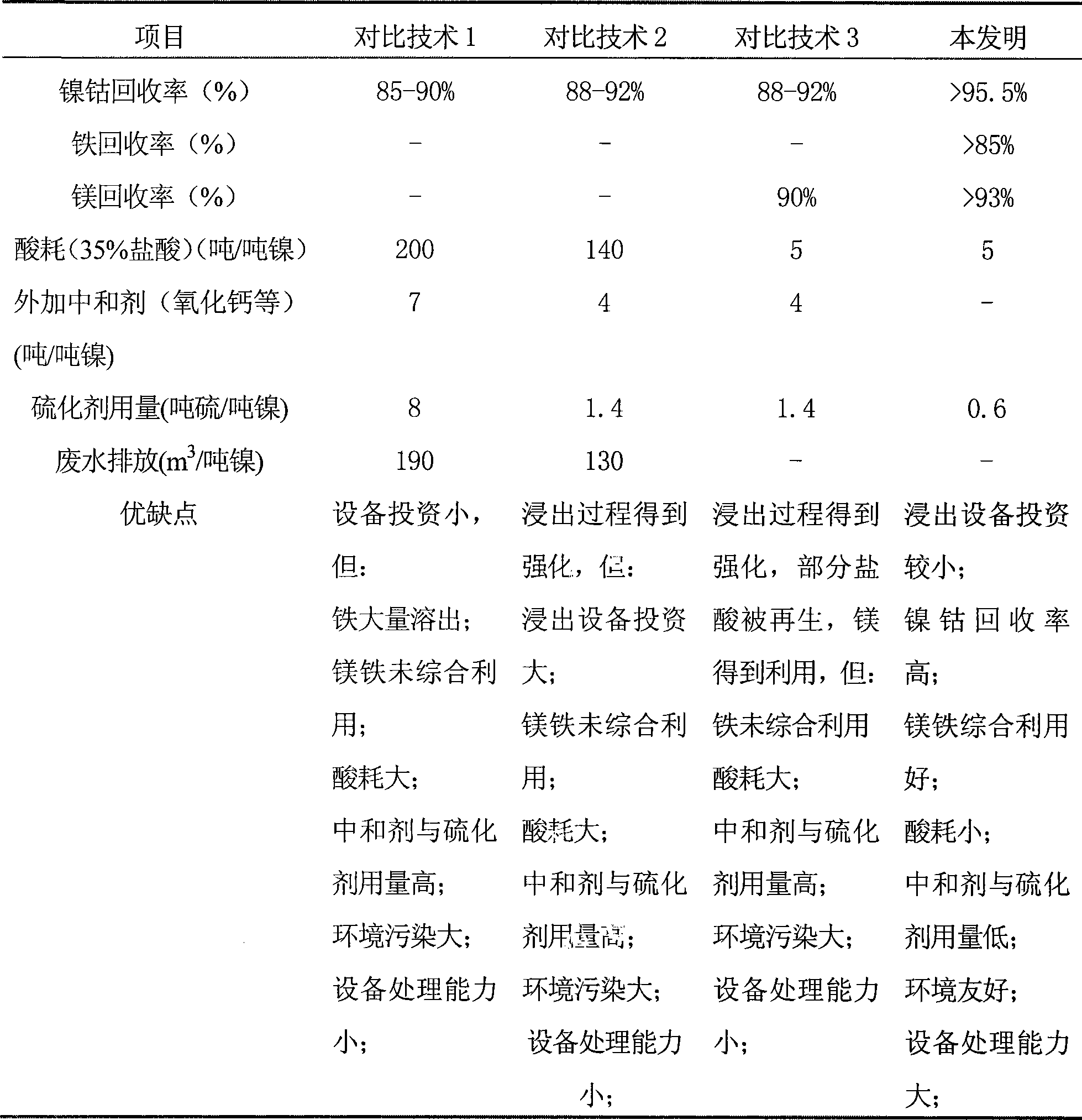

A laterite nickel ore and closed-circuit circulation technology, which is applied in chemical instruments and methods, improvement of process efficiency, solid separation, etc., can solve problems such as high energy consumption, low equipment capacity, and high cost of hydrochloric acid regeneration, so as to reduce acid consumption and equipment The effect of reducing investment and maintenance costs and improving comprehensive utilization value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0091] (1) Leaching

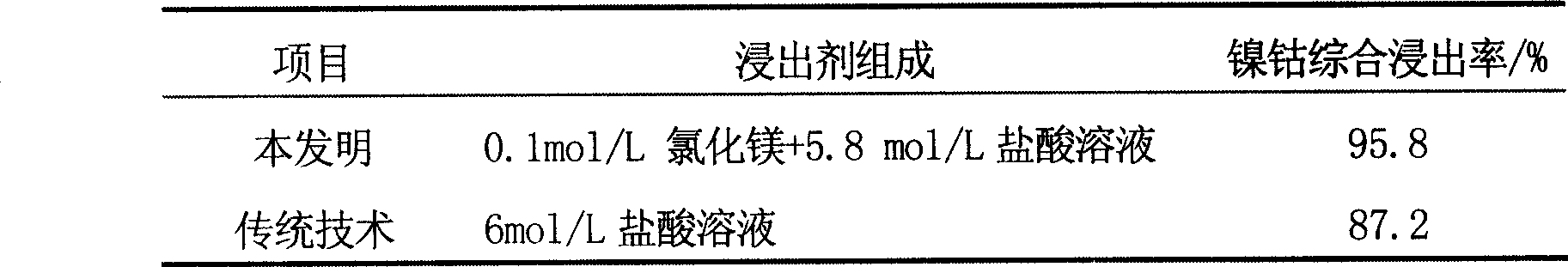

[0092] A. Add water according to the material-to-water ratio of 1:2 (wt) to ball mill the laterite nickel ore and pass it through a 100-mesh sieve. Take -100 mesh slurry and pump it into the pressure reactor, pump water and chloride leaching agent (HCl content above 28%, magnesium ion The sum of iron ion content: the content of chloride ion is 0.05:1 (wt)), stirring and leaching.

[0093] B. Control of leaching conditions: stirring and leaching for 2 hours at 150° C. (maximum pressure control is 0.3 MPa).

[0094] C. Filter while hot and wash the residue. The comprehensive leaching rates of valuable metals are: Ni+Co 95.8%; Mg 95.0%; Fe4.6%.

[0095] After pressure leaching of laterite nickel ore with chloride, the contents of nickel and cobalt in the leaching solution (g / L) are: Ni+Co 2.27; Mg33.5 Fe2.16; the acidity of the leaching solution is: H + 0.82mol / L. The following examples are based on this leachate.

[0096] The valuable metal components...

Embodiment 2

[0110]Carry out the extraction and comprehensive utilization of valuable metals in the laterite nickel ore in the same manner as in Example 1, but step (1) wherein is carried out in the following manner:

[0111] A. Add water according to the material-to-water ratio of 1:1 (wt) to ball-mill the laterite nickel ore and pass through a 100-mesh sieve. Get the -100 mesh slurry and pump it into the pressure reactor, and pump water and chloride leaching agent (hydrochloric acid and the mother liquor after extracting nickel and cobalt) into the liquid-solid ratio of 3.0:1 and the leaching agent to material (weight) ratio of 1.4:1. In the mixed solution, the content of HCl is more than 28%, the sum of the content of magnesium ion and iron ion: the content of chloride ion is 0.1:1), stirring and leaching.

[0112] B. Control of leaching conditions: stirring and leaching for 1 hour at 165° C. (maximum pressure control is 0.45 MPa).

[0113] C. Filter while hot and wash the residue. Th...

Embodiment 3

[0115] Carry out the extraction and comprehensive utilization of valuable metals in the laterite nickel ore in the same manner as in Example 1, but step (1) wherein is carried out in the following manner:

[0116] D. Add water according to the material-to-water ratio of 1:1 (wt) to ball-mill the laterite nickel ore and pass through a 100-mesh sieve. Get the -100 mesh slurry and pump it into the pressure reactor, and pump water and chloride leaching agent (magnesium chloride, chlorine, etc. The mixed solution of ferric chloride and hydrochloric acid, the content of HCl is more than 28%, the sum of the content of magnesium ion and iron ion: the content of chloride ion is 0.3:1), stirring and leaching.

[0117] E. Control of leaching conditions: stirring and leaching for 0.5 hours at 180° C. (maximum pressure control is 0.5 MPa).

[0118] F. Filtrate while hot and wash the residue. The comprehensive leaching rates of valuable metals are: Ni+Co 96.1%; Mg 95.6%; Fe 3.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com