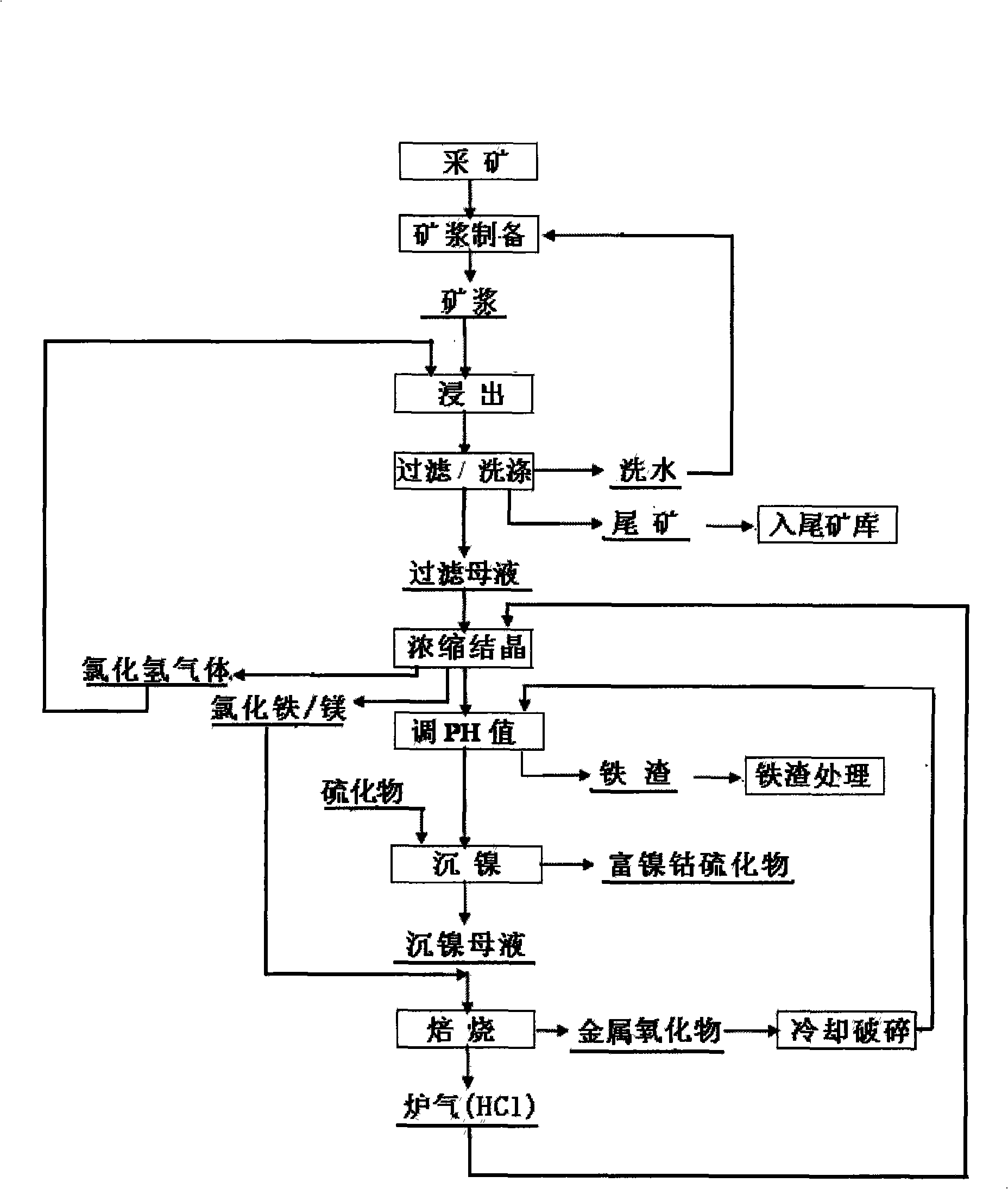

Process for abstracting nickel and cobalt by using wet method to chloridize laterite-nickel ore

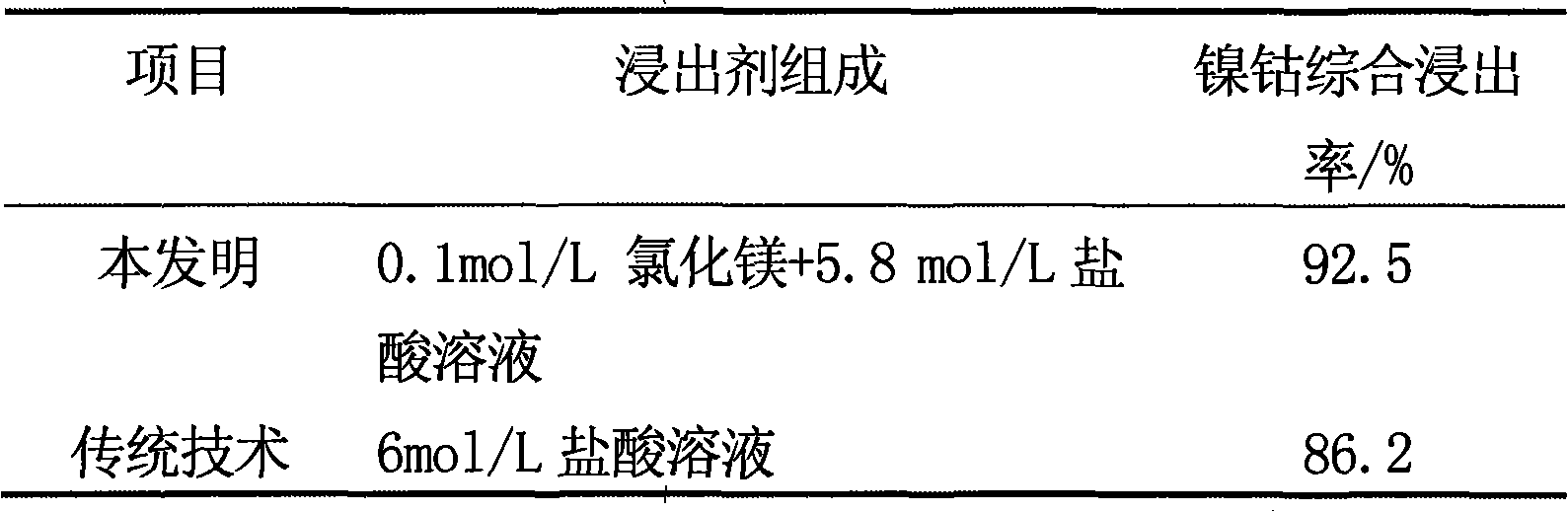

A technology of lateritic nickel ore and nickel-cobalt, which is applied in the direction of improving process efficiency, can solve the problems of unqualified environmental protection process, small production scale, and high environmental protection pressure, so as to improve leaching efficiency and hydrochloric acid utilization rate, and eliminate system expansion phenomenon , the effect of enhanced reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The laterite nickel ore is ball milled and passed through a 50-mesh sieve, and a -50-mesh ore sample is taken for leaching.

[0032] The chloride leaching agent used is a mixed solution of magnesium chloride, ferrous chloride and hydrochloric acid, in which the sum of the content of magnesium ion and iron ion: the content of chloride ion is 0.02:1 (mass ratio).

[0033] According to the liquid-solid ratio 5:1, Cl - The mass ratio to the material is 1.4, add water and chloride leaching agent respectively, heat up to 50°C and stir for 1 hour; then heat up to 70°C and stir for 1 hour; then heat up to 90°C and stir for 1 hour, the total leaching time is controlled 3 hours. Filter while hot to obtain leaching residue and leaching liquid.

[0034] The residue was analyzed, and it was determined that the nickel leaching rate was 89.12% and the cobalt leaching rate was 94.15%.

Embodiment 2

[0036] The laterite nickel ore is ball milled and passed through a 50-mesh sieve, and a -50-mesh ore sample is taken for leaching.

[0037] The chloride leaching agent used is a mixed solution of magnesium chloride, ferrous chloride and hydrochloric acid, in which the sum of the content of magnesium ions and iron ions: the content of chloride ions is 0.1:1 (mass ratio).

[0038] According to the liquid-solid ratio 5:1, Cl - The mass ratio to the material is 1.4, add water and chloride leaching agent respectively, heat up to 50°C and stir for 1 hour; then heat up to 70°C and stir for 1 hour; then heat up to 90°C and stir for 1 hour, the total leaching time is controlled 3 hours. Filter while hot to obtain leaching residue and leaching liquid.

[0039] The residue was analyzed, and it was determined that the nickel leaching rate was 90.23% and the cobalt leaching rate was 94.36%.

Embodiment 3

[0041] The laterite nickel ore is ball milled and passed through a 50-mesh sieve, and a -50-mesh ore sample is taken for leaching.

[0042] The chloride leaching agent used is a mixed solution of ferric chloride, calcium chloride, aluminum chloride and hydrochloric acid, in which the sum of iron ion, calcium ion and aluminum ion content: the content of chloride ion is 0.3:1 (mass ratio).

[0043] According to the liquid-solid ratio 5:1, Cl - The mass ratio to the material is 1.4, add water and chloride leaching agent respectively, heat up to 50°C and stir for 1 hour; then heat up to 70°C and stir for 1 hour; then heat up to 90°C and stir for 1 hour, the total leaching time is controlled 3 hours. Filter while hot to obtain leaching residue and leaching liquid.

[0044] The residue was analyzed and it was determined that the nickel leaching rate was 89.01% and the cobalt leaching rate was 94.03%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com