Preparation method of mesoporous carbon material with high specific surface area

A high specific surface area, porous carbon technology, which is applied in the field of preparation of high specific surface area mesoporous carbon materials, can solve the problems that it is difficult to meet high specific surface area at the same time, the template agent cannot be reused, and the economy is poor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022]Example 1 Dissolve 10g of glucose, 1g of resorcinol and 1g of ferrous chloride in water, then transfer to 85°C oil bath or water bath, heat and stir, hydrolyze and polymerize for about 0.5h to obtain a black viscous mixture, take out Dry and solidify in an oven at 180°C for 0.1h to obtain a black solid. Transfer the black solid to a carbonization furnace, raise the temperature to 350°C in flowing helium, carbonize at a constant temperature for 0.5h, cool to room temperature, and take out the carbonized solid product. Boil with dilute hydrochloric acid and distilled water, filter and wash several times while hot, until the filtrate is tested with silver nitrate solution to detect the presence of no chloride ions, and then dry to obtain the mesoporous carbon product. Its specific surface area is 513m 2 / g, total pore volume 1.2cm 3 / g, the average pore diameter is 2.3nm, and the mesoporosity is 85%.

Embodiment 2

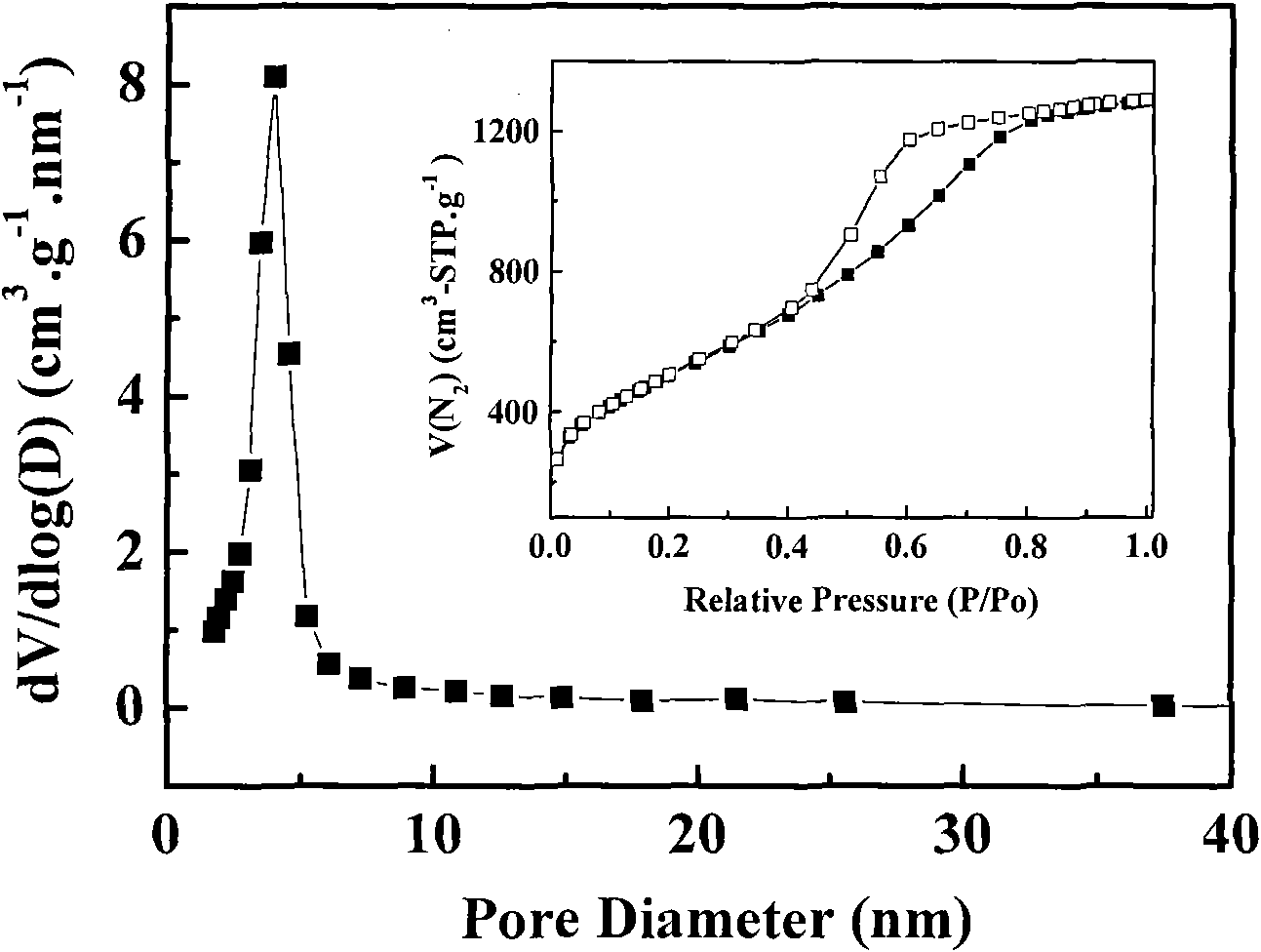

[0023] Example 2 Dissolve 10g fructose, 0.1g phenol and 12g cobalt chloride in water, then transfer to 82°C oil bath or water bath, heat and stir, hydrolyze and polymerize for 3 hours to obtain a black viscous mixture, take it out and put it in an oven at 115°C Dry and solidify in medium for 0.5h to obtain a black solid. Transfer the black solid to a carbonization furnace, raise the temperature to 380°C in a flowing argon atmosphere, carbonize at a constant temperature for 1h, cool to room temperature, take out the carbonized solid product, and wash with dilute hydrochloric acid and distilled water successively. Boil, filter and wash several times while hot, until the filtrate is tested with silver nitrate solution to detect the presence of no chloride ions, and dry to obtain the mesoporous carbon product. Its specific surface area is 995m 2 / g, total pore volume 1.7cm 3 / g, the average pore diameter is 3.5nm, and the mesoporosity is 92%.

Embodiment 3

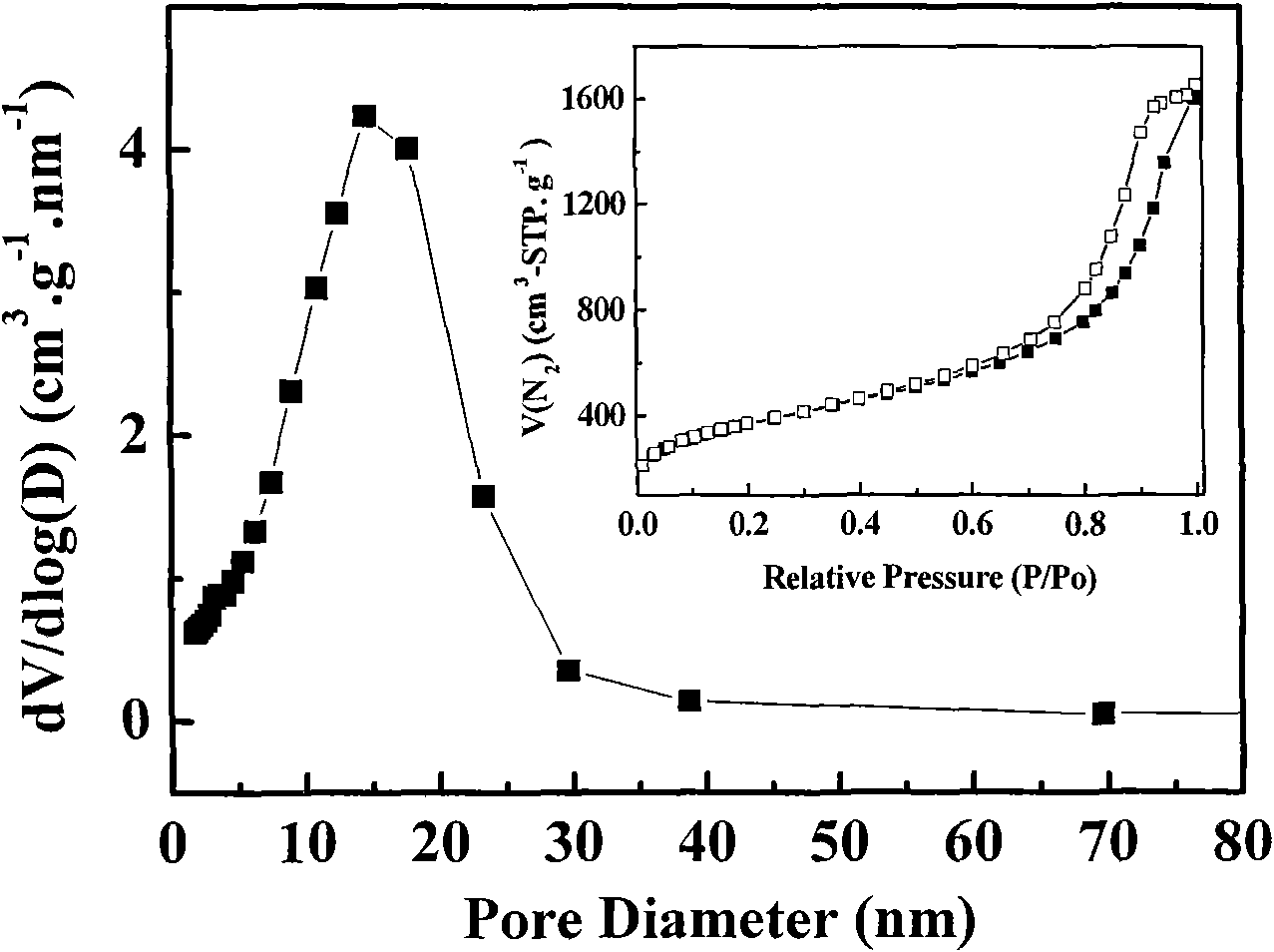

[0024] Example 3 Dissolve 10g of white sugar, 3g of methyl phenol and 5g of nickel chloride in water, then transfer to an 85°C oil bath or water bath for heating and stirring, hydrolysis and polymerization for 2 hours to obtain a brown-black viscous mixture, take it out and put it in 125 Dry and solidify in an oven at ℃ for 1 hour to obtain a black solid. Transfer the black solid to a carbonization furnace, heat up to 400°C in a flowing nitrogen atmosphere, carbonize at a constant temperature for 1.5 hours, and cool to room temperature; take out the carbonized solid product, and use dilute hydrochloric acid and Boil in distilled water, filter and wash several times while it is hot, until the filtrate is tested with silver nitrate solution to detect the presence of no chloride ions, and dry to obtain the mesoporous carbon product. Its specific surface area is 835m 2 / g, total pore volume 1.4cm 3 / g, the average pore diameter is 3.8nm, and the mesoporosity is 90%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com