Metallurgy miscellaneous material fast spectral analysis method

A spectral analysis and rapid technology, applied in the field of spectral analysis, to avoid pollution and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

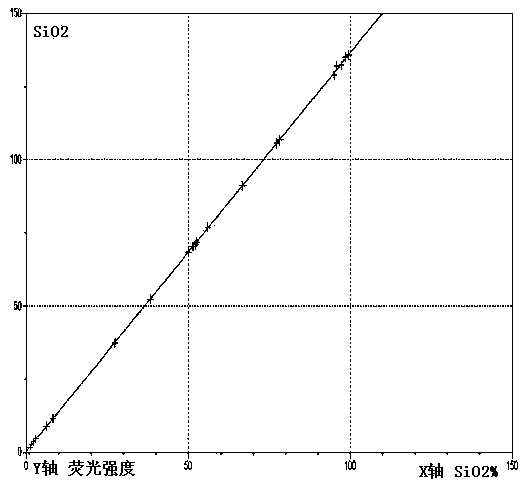

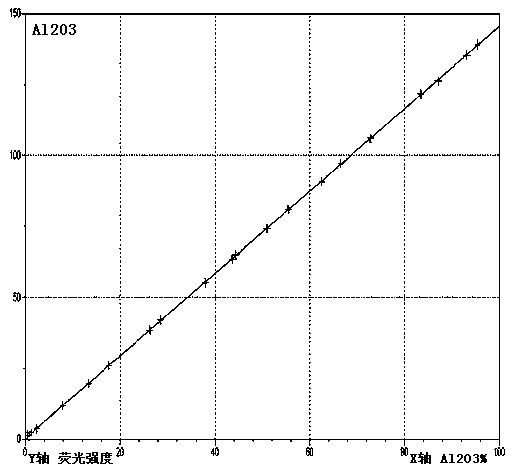

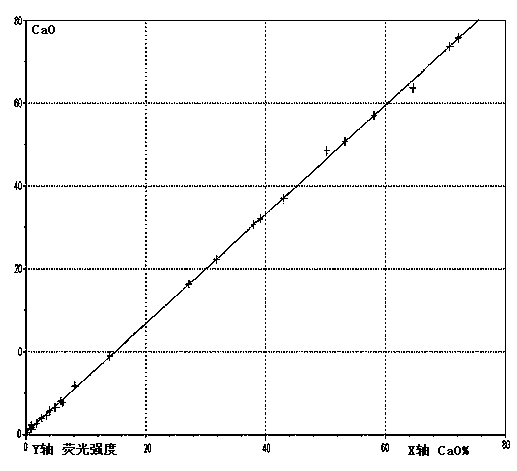

Image

Examples

Embodiment Construction

[0044] The spectral analysis equipment in this case adopts Panalytical X-ray fluorescence spectrometer, a method for rapid spectral analysis of metallurgical miscellaneous materials. The method includes sample preparation methods and drawing of working curves.

[0045] The sample preparation method comprises the following steps:

[0046] 1. The sample is burned in a high-temperature furnace, and the burning reduction (increase) is calculated;

[0047] 2. Use 7.0g of the substrate as a mixed flux of lithium tetraborate + lithium carbonate (80%+20% by mass), accurately weigh 0.700g of the sample and place it in a platinum crucible, add 3.0g of ammonium nitrate and mix well, and On the surface of the sample after mixing, 3.5g of lithium tetraborate+lithium carbonate mixed flux is uniformly covered;

[0048] 3. Add 5 drops of ammonium iodide (mass percent concentration: 10%) as a release agent, carry out low-temperature pre-oxidation in a high-temperature furnace for 15 minutes, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com