Preparing method of perovskite solar cell and perovskite solar cell

A solar cell and perovskite technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of difficult preparation of large areas and low utilization rate of solar cell raw materials, so as to achieve large-scale industrial production and improve the use of raw materials rate, the effect of improving the reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

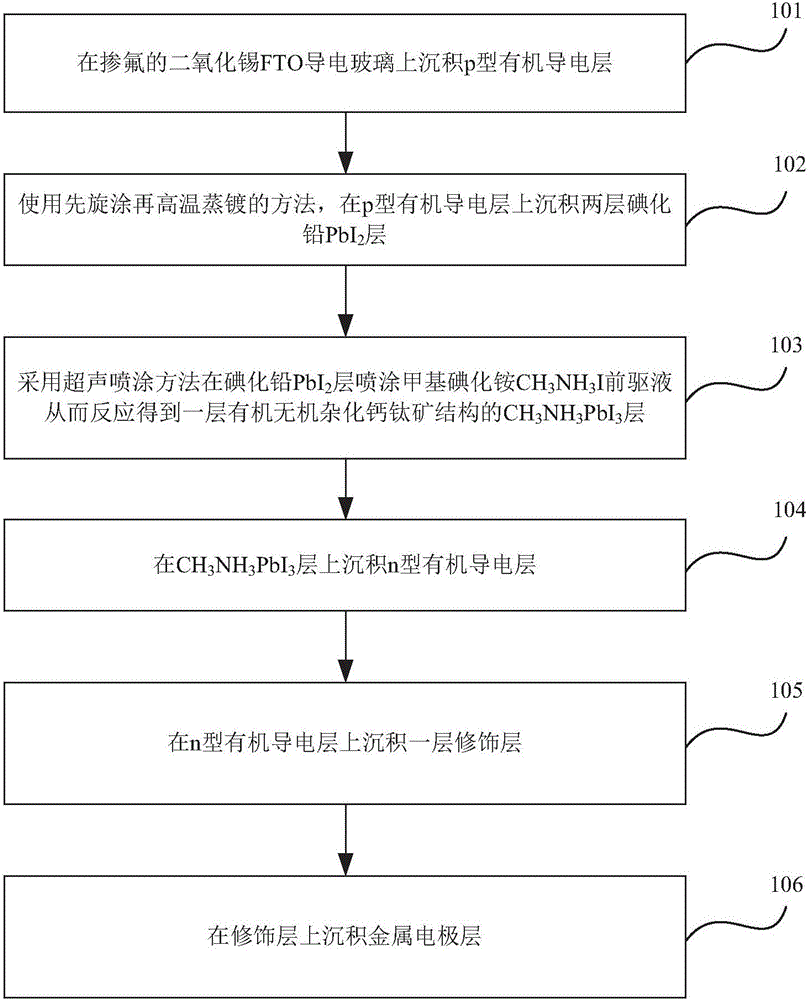

[0028] like figure 1 As shown, it is a flow chart of a preparation method of a perovskite solar cell according to an embodiment of the present invention, and the method includes:

[0029] 101. Deposit a p-type organic conductive layer on the fluorine-doped tin dioxide FTO conductive glass;

[0030] 102. Deposit two layers of lead iodide (PbI) on the p-type organic conductive layer by first spin coating and then high temperature evaporation 2 Floor;

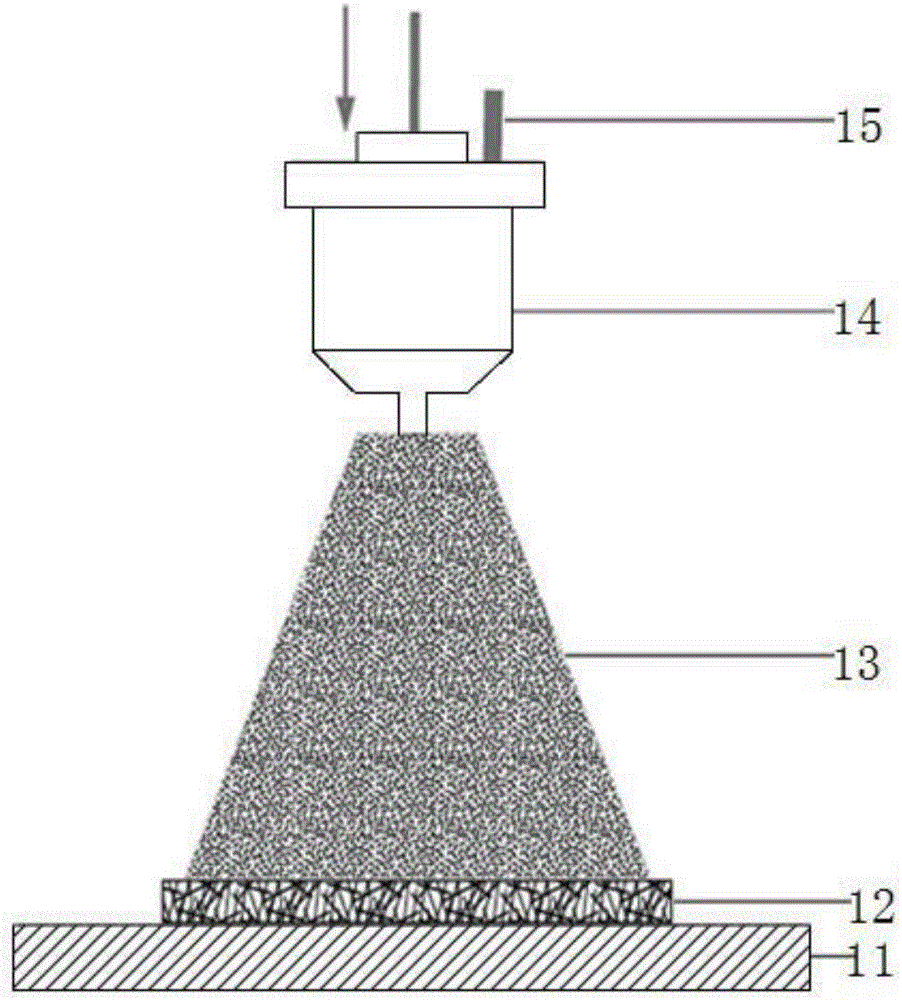

[0031] 103. Using ultrasonic spraying method on lead iodide PbI 2 Layer Spray Methyl Ammonium Iodide CH 3 NH 3 I precursor solution reacts to obtain a layer of organic-inorganic hybrid perovskite structure CH 3 NH 3 PbI 3 Floor;

[0032] 104. In CH 3 NH 3 PbI 3 depositing an n-type organic conductive layer on the layer;

[0033] 105. Deposit a layer of modification layer on the n-type organic conductive layer;

[0034] 106. Deposit a metal electrode layer on the modification layer.

[0035] Preferably, the depositing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sheet resistance | aaaaa | aaaaa |

| Layer thickness | aaaaa | aaaaa |

| Layer thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com