Perovskite material, application thereof on solar cell and preparation method of solar cell

A perovskite material, a technology for solar cells, applied in the field of solar cells, can solve problems such as low energy conversion efficiency, lead-based perovskite pollutes the environment, and affects human health, and achieves electron and hole mobility improvement and cost advantages. , the effect of increasing mechanical stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

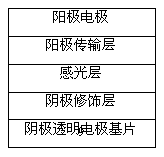

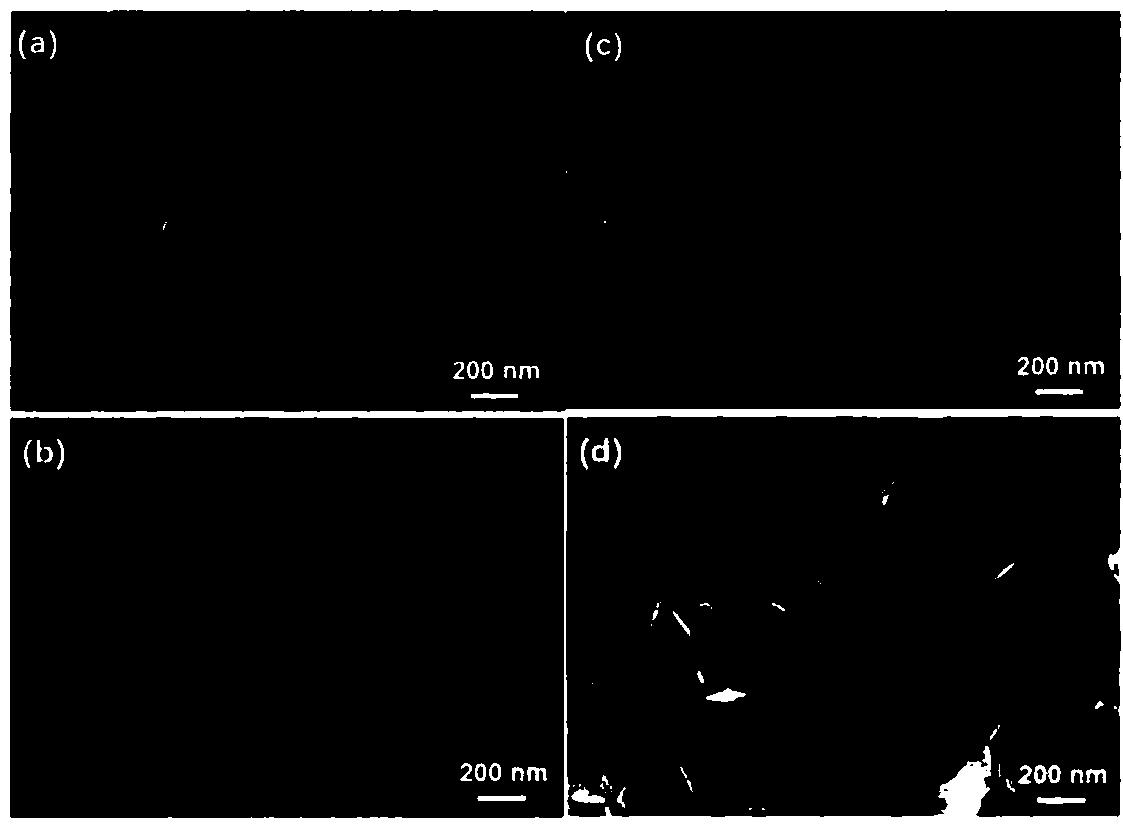

[0031] A method for preparing a lead-tin-copper ternary high-efficiency perovskite solar cell, the preparation steps of the preparation method are as follows:

[0032] (1) Dissolve 190mg of methylammonium iodide, 510mg of lead iodide, 20mg of tin iodide and 13mg of copper bromide in a mixed solvent of γ-butyrolactone and dimethyl sulfoxide (volume ratio 7:3 ), stirred for 5h to make a perovskite solution with a concentration of 40wt%;

[0033] (2) Hydrolyzing titanium tetrachloride at a low temperature of 70°C to obtain a titanium dioxide electron transport layer with good charge transport properties, forming a cured cathode modification layer with a thickness of 45 nm;

[0034] (3) Spin-coat the perovskite γ-butyrolactone and dimethyl sulfoxide solution obtained in (1) on the cathode modification layer obtained in (2) at a speed of 4000 rpm for 40 seconds, and then Lower annealing for 10 minutes to obtain a uniformly cured photosensitive layer with a thickness of 250 nm;

...

Embodiment 2

[0038] A preparation method of a lead-copper perovskite solar cell, the preparation steps of the preparation method are as follows:

[0039] (1) Dissolve 190 mg of methyl ammonium iodide, 530 mg of lead iodide and 13 mg of copper bromide in a mixed solvent of γ-butyrolactone and dimethyl sulfoxide (volume ratio 7:3), and stir for 5 hours. Making concentration is the perovskite solution of 40wt%;

[0040] (2) Hydrolyzing titanium tetrachloride at a low temperature of 70°C to obtain a titanium dioxide electron transport layer with good charge transport properties, forming a cured cathode modification layer with a thickness of 45 nm;

[0041] (3) Spin-coat the perovskite γ-butyrolactone and dimethyl sulfoxide solution obtained in (1) on the cathode modification layer obtained in (2) at a speed of 4000 rpm for 40 seconds, and then Lower annealing for 10 minutes to obtain a uniformly cured photosensitive layer with a thickness of 300 nm;

[0042] (4) Spin-coat 2,2',7,7'-tetrakis[N,...

Embodiment 3

[0045] A method for preparing a lead-tin-copper ternary high-efficiency perovskite solar cell, the preparation steps of the preparation method are as follows:

[0046] (1) Dissolve 190mg of methylammonium iodide, 470mg of lead iodide, 33.5mg of tin iodide and 20mg of copper bromide in a mixed solvent of γ-butyrolactone and dimethyl sulfoxide (volume ratio 7: 3), stirring for 5 hours to make a perovskite solution with a concentration of 35wt%;

[0047] (2) Hydrolyzing titanium tetrachloride at a low temperature of 70°C to obtain a titanium dioxide electron transport layer with good charge transport properties, forming a cured cathode modification layer with a thickness of 20 nm;

[0048] (3) Spin-coat the perovskite γ-butyrolactone and dimethyl sulfoxide solution obtained in (1) on the cathode modification layer obtained in (2) at a speed of 3500 rpm for 60 seconds, and then Lower annealing for 15 minutes to obtain a uniformly cured photosensitive layer with a thickness of 320...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com