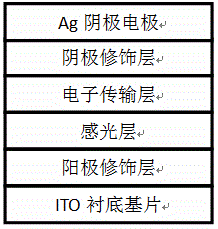

Preparation method of cathode and anode-modified perovskite solar cell

A solar cell and perovskite-type technology, applied in the field of solar cells, can solve problems such as poor visible light absorption rate, poor energy conversion efficiency, and large thickness, and achieve the effects of increasing fill factor, improving device efficiency, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

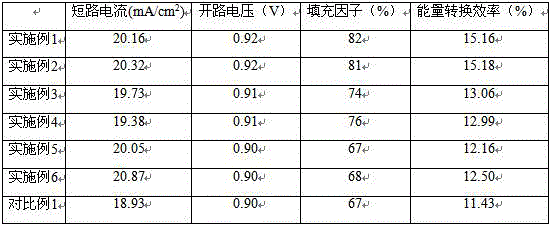

Examples

Embodiment 1

[0026] A method for preparing a perovskite solar cell modified by a cathode and an anode, the preparation steps are as follows:

[0027] (1) Dissolve methylammonium iodide and lead chloride in dimethylformamide at a molar ratio of 3:1, and stir for 5 hours to prepare a 30wt% perovskite precursor;

[0028] (2) After dissolving Ag nanoparticles in ethanol, and then miscible with PEDOT:PSS, the solution was processed on the ITO glass substrate by rotating at 4500rpm for 40s, and then annealed in air at 100°C for 20min to obtain a thickness of The cured anode modification layer of 50nm, wherein the weight ratio of Ag nanoparticles, ethanol, PEDOT:PSS is 3:7:50, and the particle size of Ag nanoparticles is 40-50nm;

[0029] (3) The perovskite precursor solution in (1) was processed on the anode modification layer in (2) by rotating at 4000rpm for 40s, and then annealed in nitrogen at 100°C for 1h to obtain a cured layer with a thickness of 300nm. photosensitive layer;

[0030] (4...

Embodiment 2

[0034] A method for preparing a perovskite solar cell modified by a cathode and an anode, the preparation steps are as follows:

[0035] (1) Dissolve methylammonium iodide and lead chloride in dimethylformamide at a molar ratio of 3:1, and stir for 5 hours to prepare a 30wt% perovskite precursor;

[0036] (2) After dissolving Ag nanoparticles in ethanol, and then miscible with PEDOT:PSS, the solution was processed on the ITO glass substrate by rotating at 4500rpm for 40s, and then annealed in air at 100°C for 20min to obtain a thickness of The cured anode modification layer of 50nm, wherein the weight ratio of Ag nanoparticles, ethanol, PEDOT:PSS is 3:7:50, and the particle size of Ag nanoparticles is 40-50nm;

[0037] (3) The perovskite precursor solution in (1) was processed on the anode modification layer in (2) by rotating at 4000rpm for 40s, and then annealed in nitrogen at 100°C for 1h to obtain a cured layer with a thickness of 300nm. photosensitive layer;

[0038] (4...

Embodiment 3

[0042] A method for preparing a perovskite solar cell modified by a cathode and an anode, the preparation steps are as follows:

[0043] (1) Dissolve methylammonium iodide and lead chloride in dimethylformamide at a molar ratio of 3:1, and stir for 5 hours to prepare a 30wt% perovskite precursor;

[0044] (2) After dissolving Ag nanoparticles in ethanol, and then miscible with PEDOT:PSS, the solution was processed on the ITO glass substrate by rotating at 4500rpm for 40s, and then annealed in air at 100°C for 20min to obtain a thickness of The cured anode modification layer of 50nm, the weight ratio of Ag nanoparticles, ethanol, PEDOT:PSS is 3:7:50, and the particle size of Ag nanoparticles is 40-50nm;

[0045] (3) The perovskite precursor solution in (1) was processed on the anode modification layer in (2) by rotating at 4000rpm for 40s, and then annealed in nitrogen at 100°C for 1h to obtain a cured layer with a thickness of 300nm. photosensitive layer;

[0046] (4) Proces...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com