Antibacterial powder coating for pipeline

A technology for powder coatings and pipes, applied in the field of coatings, can solve problems such as no effect, and achieve the effects of improving anti-corrosion performance, simple process, beautiful and practical products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

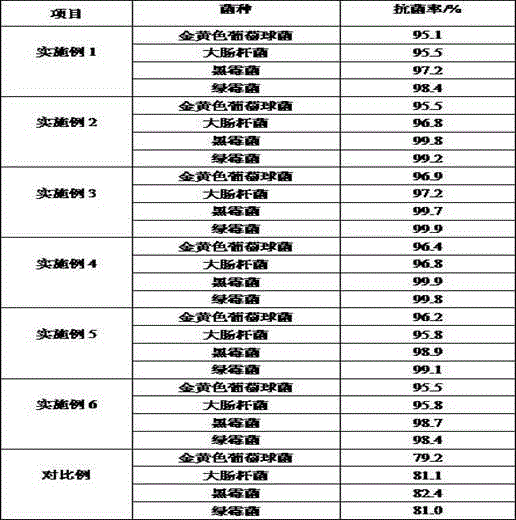

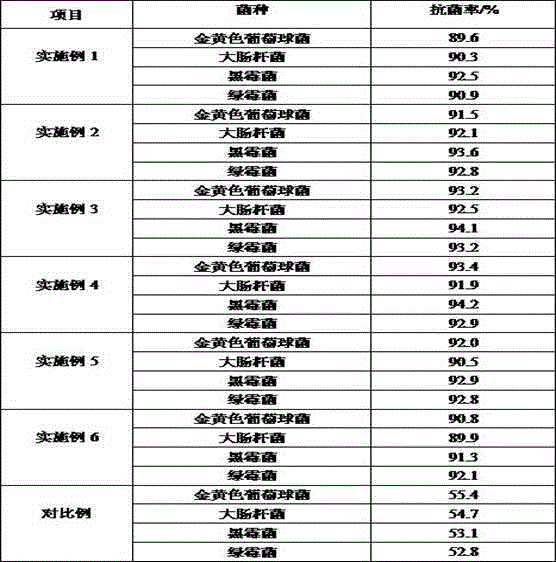

Examples

Embodiment 1

[0028] An antibacterial powder coating for pipelines is characterized in that it is composed of the following raw materials in parts by weight: 60 parts of polyethylene resin powder, 30 parts of filler, 1.5 parts of tetramethylammonium iodide, 5 parts of reinforcing agent, corrosion inhibitor 4 parts of agent, 8 parts of antibacterial agent, 0.7 part of pigment.

[0029] The antibacterial agent is composed of nano-silver and silicon dioxide in a weight ratio of 0.4:1, and the particle size of the silicon dioxide is less than 40 μm.

[0030] The filler is composed of activated calcium carbonate, talc powder and coupled wood powder in a weight ratio of 1:0.5:1.1, and the particle diameters of the activated calcium carbonate, talc powder and coupled wood powder are all less than 50 μm.

[0031] The enhancer is composed of biochar, nano-titanium dioxide and petrolatum in a weight ratio of 1:0.8:1.5.

[0032] The corrosion inhibitor is composed of hexamethylenetetramine and sodium...

Embodiment 2

[0037] An antibacterial powder coating for pipelines is characterized in that it is composed of the following raw materials in parts by weight: 70 parts of epoxy resin powder, 28 parts of filler, 1.3 parts of tetramethylammonium iodide, 4.5 parts of reinforcing agent, corrosion inhibitor 3.5 parts of agent, 7 parts of antibacterial agent, 0.6 part of pigment.

[0038] The antibacterial agent is composed of nano-silver and silicon dioxide in a weight ratio of 0.4:1, and the particle size of the silicon dioxide is less than 40 μm.

[0039] The filler is composed of activated calcium carbonate, talc powder and coupled wood powder in a weight ratio of 1:0.5:1.1, and the particle diameters of the activated calcium carbonate, talc powder and coupled wood powder are all less than 50 μm.

[0040] The enhancer is composed of biochar, nano-titanium dioxide and petrolatum in a weight ratio of 1:0.8:1.5.

[0041] The corrosion inhibitor is composed of hexamethylenetetramine and sodium gl...

Embodiment 3

[0046] An antibacterial powder coating for pipelines is characterized in that it is composed of the following raw materials in parts by weight: 75 parts of polyethylene resin powder, 27 parts of filler, 1 part of tetramethylammonium iodide, 4 parts of reinforcing agent, corrosion inhibitor 3 parts of agent, 6 parts of antibacterial agent, 0.5 part of pigment.

[0047] The antibacterial agent is composed of nano-silver and silicon dioxide in a weight ratio of 0.4:1, and the particle size of the silicon dioxide is less than 40 μm.

[0048] The filler is composed of activated calcium carbonate, talc powder and coupled wood powder in a weight ratio of 1:0.5:1.1, and the particle diameters of the activated calcium carbonate, talc powder and coupled wood powder are all less than 50 μm.

[0049] The enhancer is composed of biochar, nano-titanium dioxide and petrolatum in a weight ratio of 1:0.8:1.5.

[0050]The corrosion inhibitor is composed of hexamethylenetetramine and sodium glu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com