Anti-drag aqueous fracturing fluid preparation

A water fracturing and preparation technology, applied in the direction of drilling compositions, chemical instruments and methods, etc., to achieve high flowback efficiency, meet large-scale and efficient development, and facilitate the effect of liquid preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

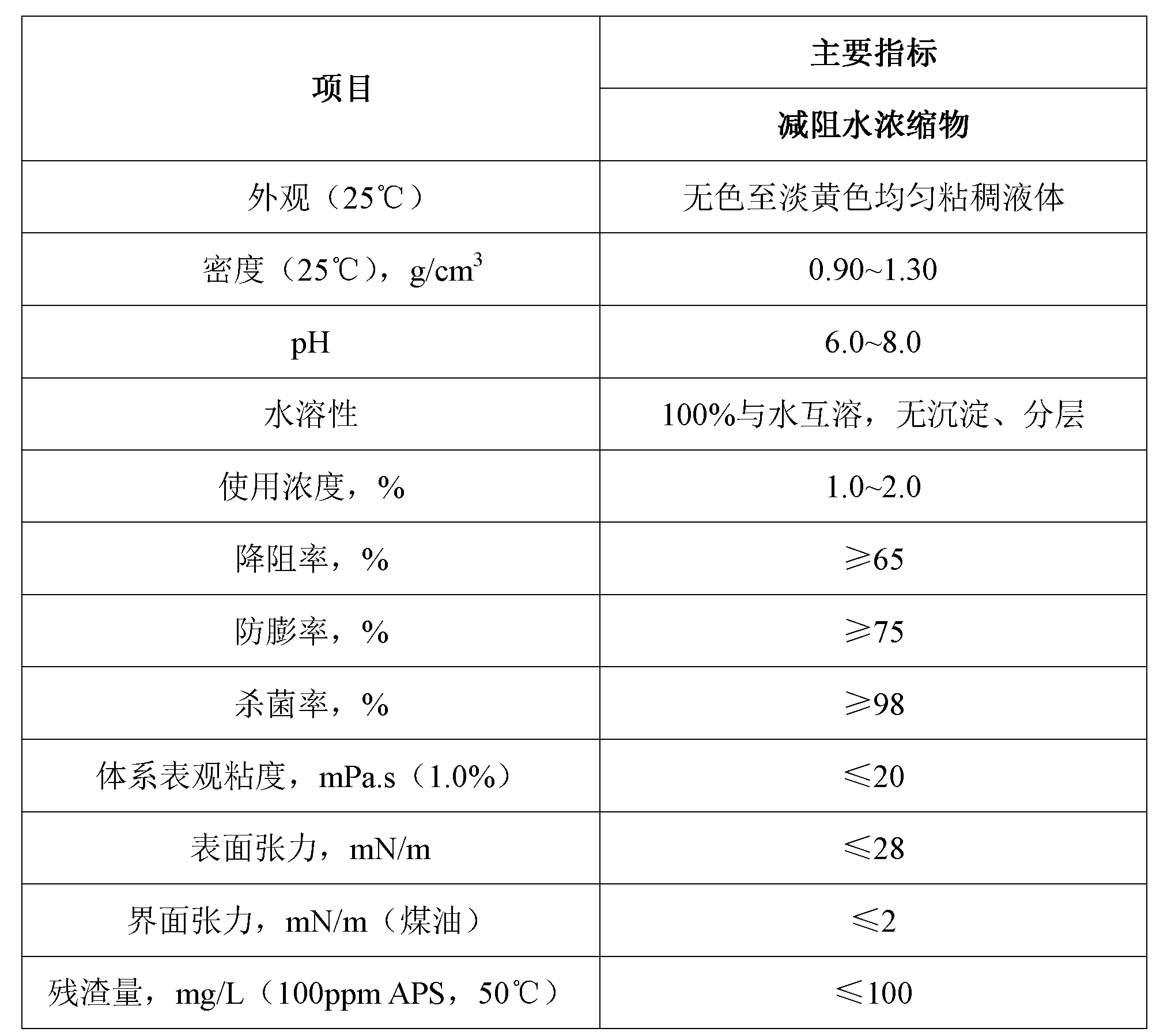

Image

Examples

Embodiment Construction

[0022] The drag-reducing water fracturing fluid formulation of the present invention will be described in detail below in conjunction with examples.

[0023] 1. Specific preparation method of drag reducer

[0024] Add propylene oxide, 0.5-1.0% hydroquinone, 20-25% acrylic acid and 0.5-1.0% propylene oxide, 0.5-1.0% hydroquinone, 20-25% acrylic acid and 0.5-1.0% mass volume ratio concentration to a 250ml three-necked flask equipped with a condenser tube, a stirrer, and a thermometer. % p-benzenesulfonic acid, heat up to 85~125°C, keep stirring for 6~12h, cool down, and treat the reaction product with 200ml dilute NaOH solution (0.2mol / L) for 2-3h to remove residual acrylic acid and hydroquinone, Vacuum drying at low temperature for 12-24 hours to obtain polyoxyethylene ether acrylate monomer.

[0025] According to the mass ratio, add 20~30% acrylamide, 30~40% polyoxyethylene ether acrylate monomer and 30~50% toluene into a three-necked flask with a stirrer and a thermometer, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com