A kind of synthetic method of Y-type mesoporous zeolite

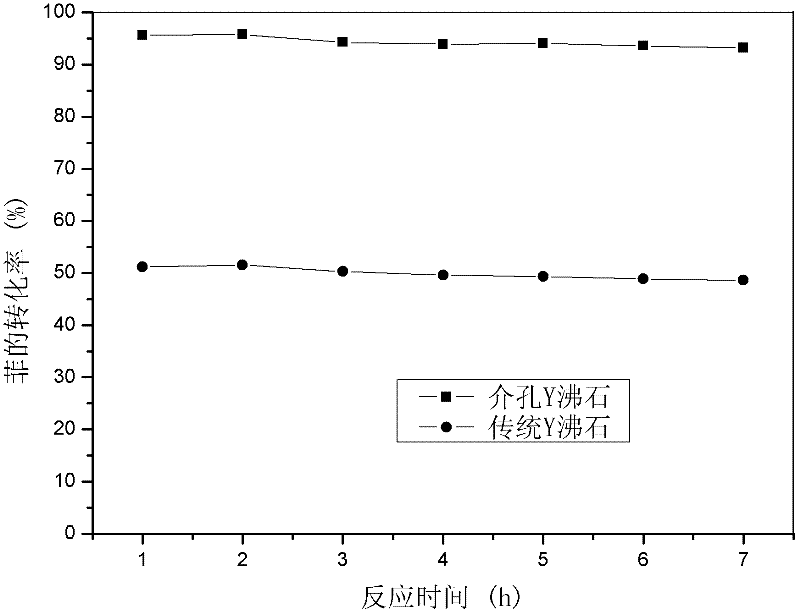

A synthesis method and technology of mesoporous zeolite, applied in the direction of crystalline aluminosilicate zeolite, octahedral crystalline aluminosilicate zeolite, etc., can solve the problem that Y-type mesoporous zeolite has not been synthesized, and achieve low equipment requirements, The effect of simple synthesis method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

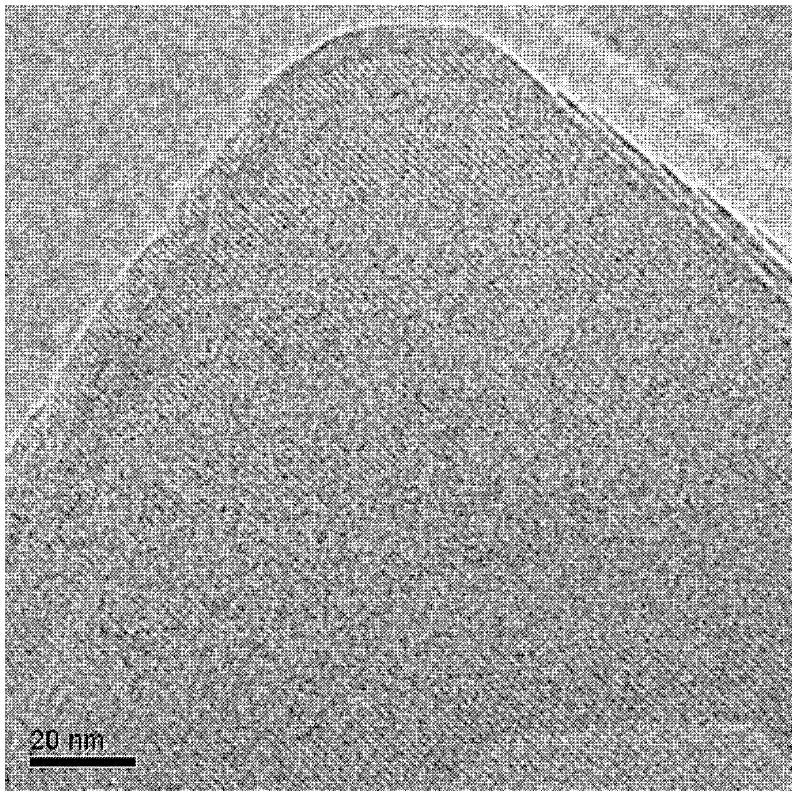

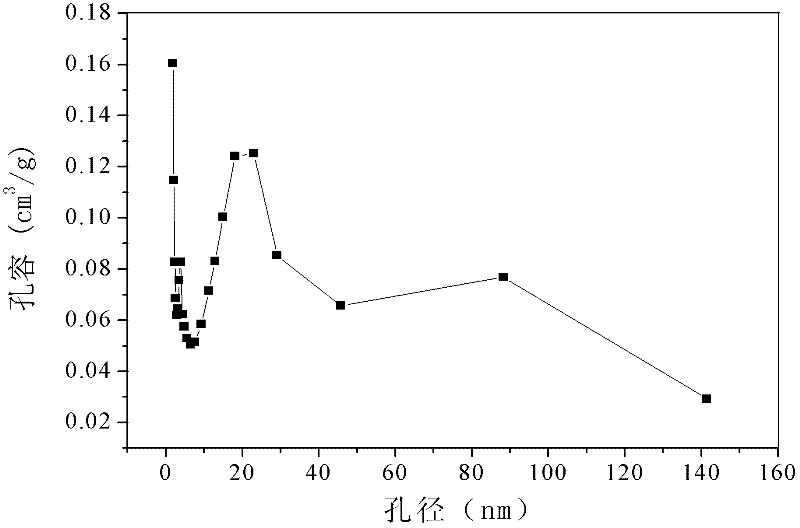

[0030] Take 25 mL of solution ①, add 3.0 mL of DM (manufactured by Guangzhou Demei Co., Ltd., the same below) and stir for 30 minutes, then add 5 mL of solution ②, stir for 1 hour, then add 6 mL of solution ③ and stir for 30 minutes, then transfer the mixture to The reaction kettle was sealed and reacted at 110° C. for 20 hours. The structural properties of the prepared mesoporous Y zeolite are shown in Table 1.

experiment example 2

[0032] Take 25mL of solution ①, add 3.0mL of DM and stir for 30 minutes, then add 5mL of solution ②, stir for 1 hour, then add 6mL of solution ③ and stir for 30 minutes, then transfer the mixture to a reaction kettle and seal it at 110°C for 36 hours. The structural properties of the prepared mesoporous Y zeolite are shown in Table 1.

experiment example 3

[0034] Take 25mL of solution ①, add 3.0mL of DM and stir for 30 minutes, then add 5mL of solution ②, stir for 1 hour, then add 6mL of solution ③ and stir for 30 minutes, then transfer the mixture to a reaction kettle and seal it at 110°C for 48 hours. The structural properties of the prepared mesoporous Y zeolite are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com