In-situ micro-nano indentation test system and method in ultrahigh-temperature water-oxygen environment

A test system, micro-nano technology, applied in the direction of testing wear resistance, measuring devices, instruments, etc., can solve problems such as stress release and inability to characterize the mechanical properties of samples

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further elaborated below through specific embodiments in conjunction with the accompanying drawings.

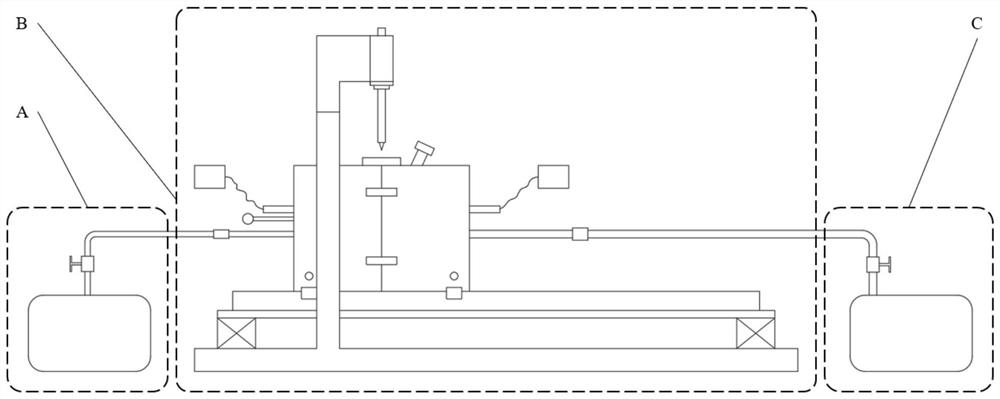

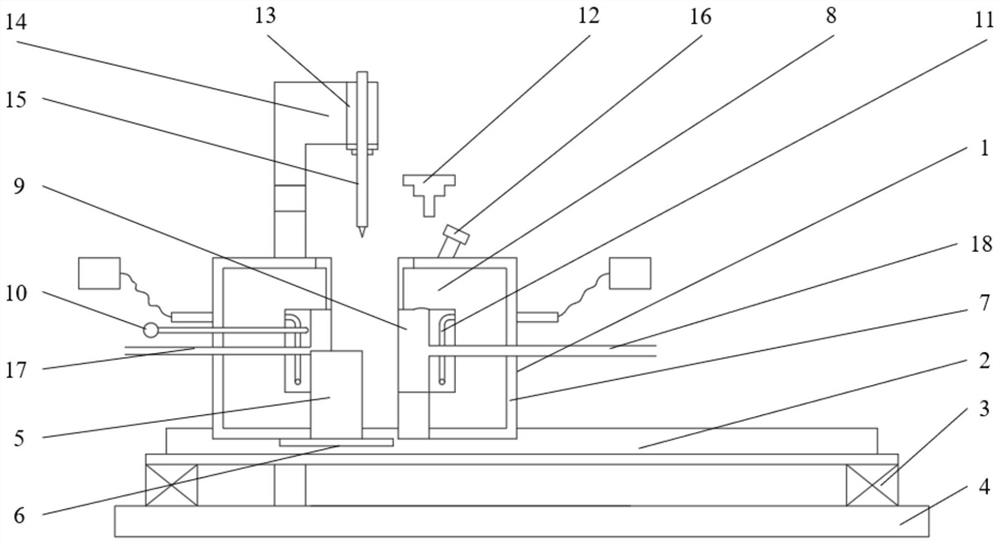

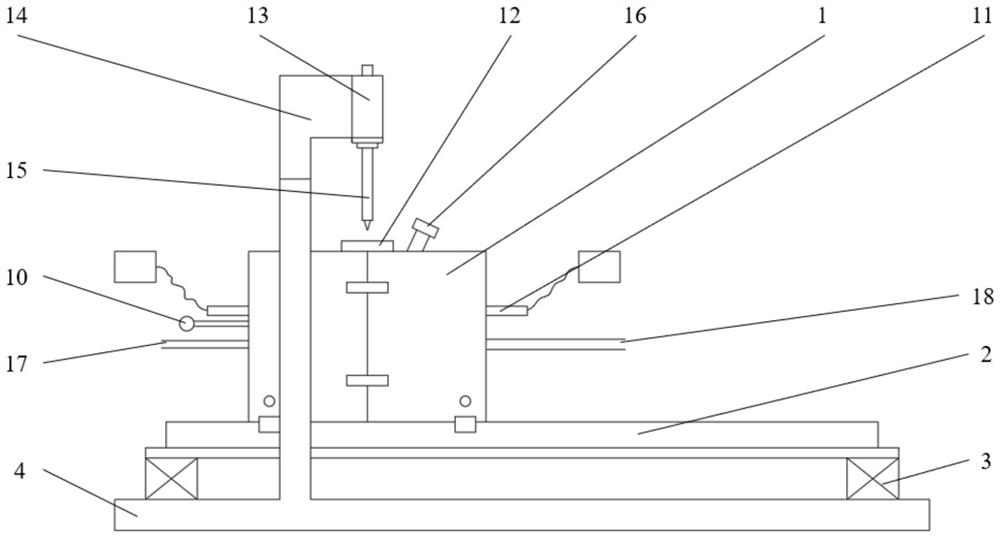

[0039] The in-situ micro-nano indentation test system in the ultra-high temperature water and oxygen environment of this embodiment includes: a gas generation device A, an ultra-high temperature water and oxygen assessment and indentation test device B, and an exhaust gas treatment device C, such as figure 1 As shown; Among them, the ultra-high temperature water oxygen assessment and indentation test device B includes: the air inlet side box, the air outlet side box 1, the slide rail 2, the flat plate, the lifting support 3, the base 4, and the sample platform 5 , Platform fixing seat 6, water cooling layer of the air inlet side box, water cooling layer of the air outlet side box 7, heat insulation layer of the air inlet side box, heat insulation layer of the air outlet side box 8, air inlet side box Protective pipe, air outlet side box pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com