Method for improving mechanical properties of amorphous endogenous composite materials through amorphous matrix structural recovery

A technology of composite materials and amorphous alloys, applied in the field of amorphous alloys and their endogenous composite materials, can solve problems such as weak hardening ability and insufficient to compensate for softening effects, and achieve significant improvement in mechanical properties, simple implementation, and clear principles Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

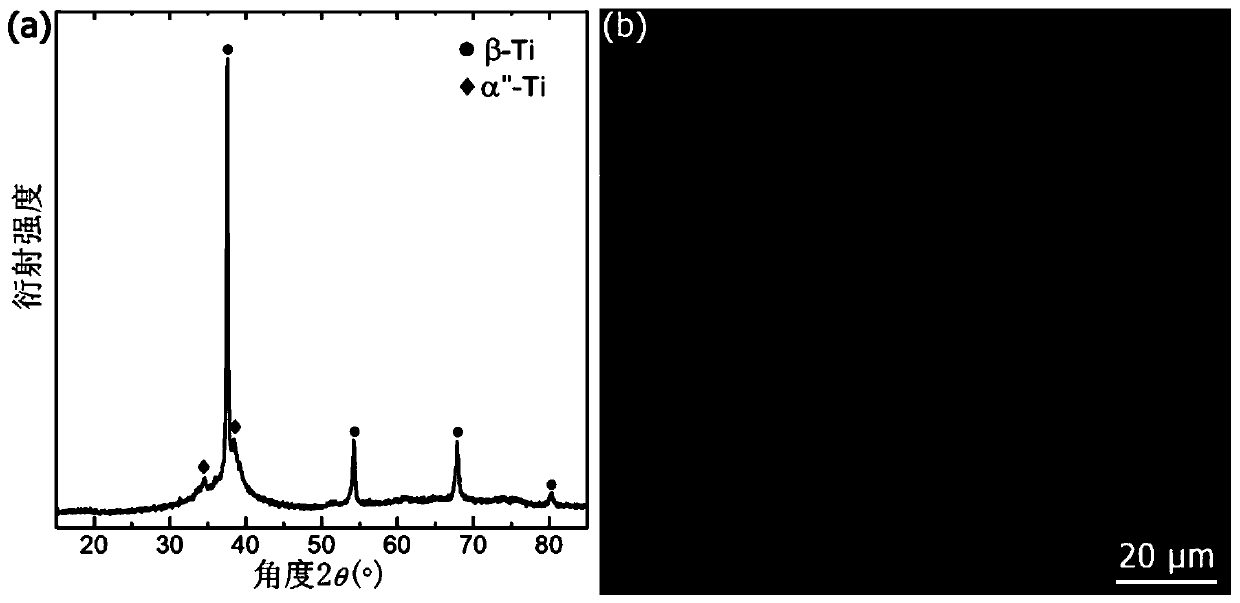

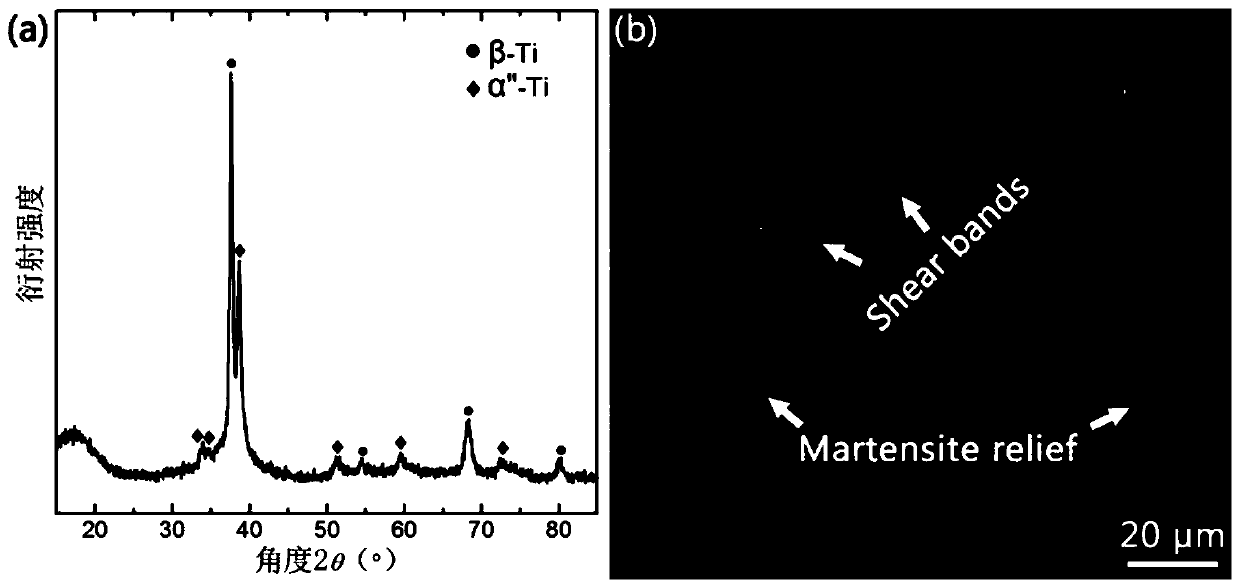

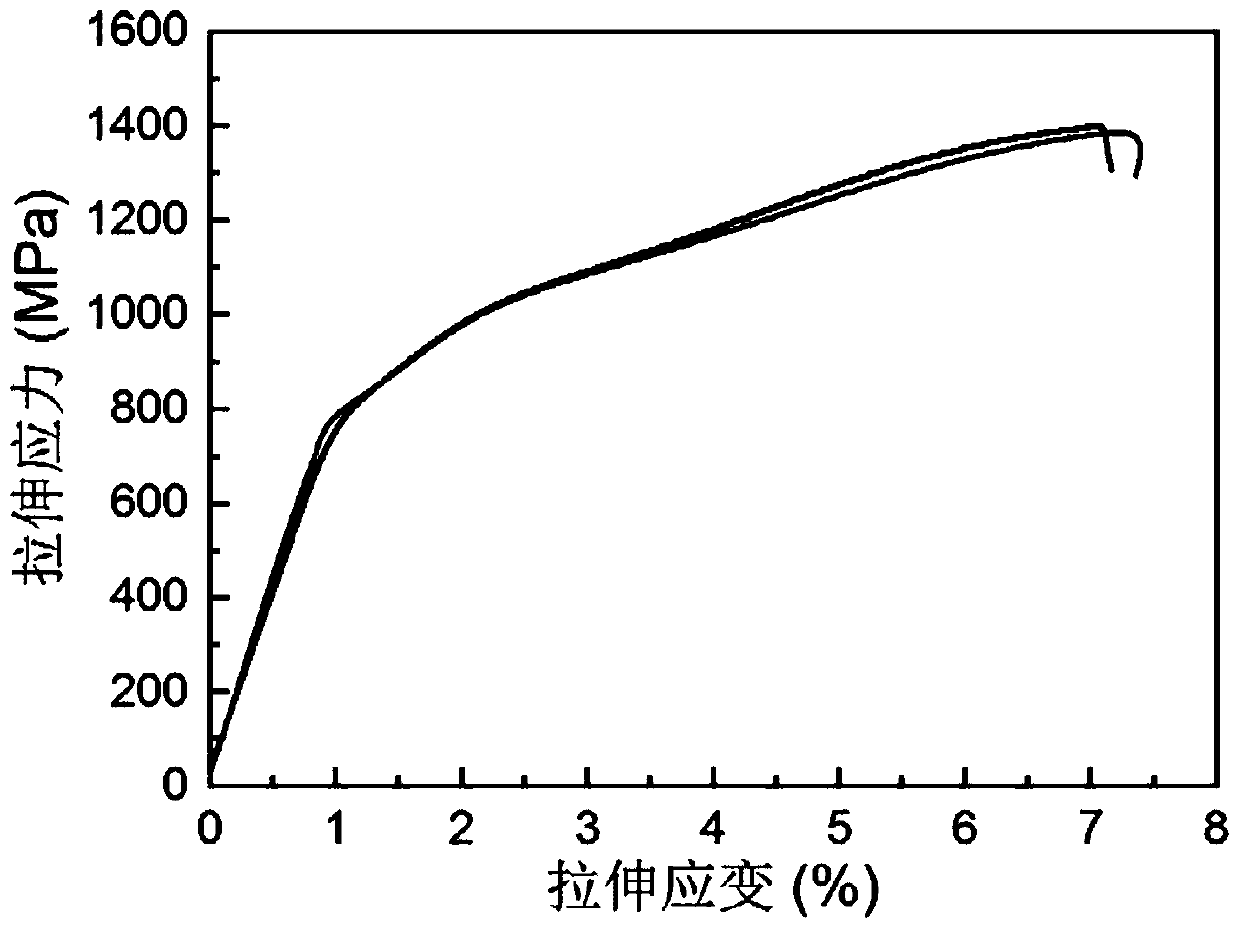

[0050] In this embodiment, the diameter is 12mm and the nominal composition is Ti 47.4 Zr 34 Cu 6 Be 12.6 The X-ray diffraction spectrum and scanning electron microscopic morphology of the round rod of amorphous endogenous composite material are as attached figure 1 Shown. The component of endogenous metastable β is Ti 63.2 Zr 34.7 Cu 2.1 , Uniformly distributed in the amorphous matrix in the form of dendrites, with a volume fraction of about 60%. Cut a thin plate from the alloy rod to take a tensile specimen. The gauge length of the tensile specimen is 14mm×2mm×0.8mm. The strain rate of the tensile test is 5×10 -4 s -1 . Ti 47.4 Zr 34 Cu 6 Be 12.6 The tensile stress-strain curve of the amorphous endogenous composite material is attached image 3 As shown, its yield strength is about 780MPa, and it exhibits tensile work hardening ability after yielding, and its tensile fracture strain is 7.2±0.2%. Ti 47.4 Zr 34 Cu 6 Be 12.6 Because of the uniform microstructure of the amorphou...

Embodiment 2

[0053] In this embodiment, the diameter is 12mm and the nominal composition is Ti 47.4 Zr 34 Cu 6 Be 12.6 The X-ray diffraction spectrum and scanning electron microscopic morphology of the round rod of amorphous endogenous composite material are as attached figure 1 Shown. The component of endogenous metastable β is Ti 63.2 Zr 34.7 Cu 2.1 , Uniformly distributed in the amorphous matrix in the form of dendrites, with a volume fraction of about 60%. Cut a thin plate from the alloy rod to take a tensile specimen. The gauge length of the tensile specimen is 14mm×2mm×0.8mm. The strain rate of the tensile test is 5×10 -4 s -1 . Ti 47.4 Zr 34 Cu 6 Be 12.6 The tensile stress-strain curve of the amorphous endogenous composite material is attached image 3 As shown, its yield strength is about 780MPa, and it exhibits tensile work hardening ability after yielding, and its tensile fracture strain is 7.2±0.2% (see attached image 3 ). Ti 47.4 Zr 34 Cu 6 Be 12.6 Because of the uniform micro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com