Lightweight functionally graded composite bulletproof armor plate and preparation method thereof

A technology of functional gradient and bulletproof equipment, applied in the direction of protective equipment, armor plate structure, chemical instruments and methods, etc., can solve problems such as weight reduction, performance limit of protective structure, and reduction of maneuverability of weapon equipment, so as to reduce weight and thickness , Realize the practical value and improve the effect of protection ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

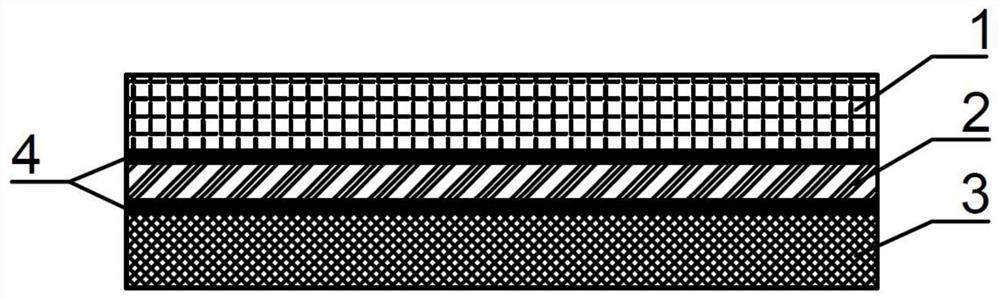

[0031] In this example, see figure 1 , a lightweight functionally graded composite bulletproof armor plate, mainly comprising a bulletproof ceramic plate (1), a shape memory alloy layer (2) and an ultra-high molecular weight polyethylene plate (3), wherein the shape memory alloy layer (2) is arranged on the bulletproof Between the ceramic plate (1) and the ultra-high molecular weight polyethylene plate (3), the shape memory alloy layer (2) is used as the core plate to form a composite structural plate, see figure 1 , between one side surface of the shape memory alloy layer (2) and the bulletproof ceramic plate (1), and between the other side surface of the shape memory alloy layer (2) and the ultra-high molecular weight polyethylene plate (3) Between them, there is an adhesive adhesive layer (4) composed of two-component fireproof adhesive. The adhesive adhesive layer (4) can connect the two layers of the shape memory alloy layer (2) to the bulletproof ceramic plate (1) and th...

Embodiment 2

[0048] This embodiment is basically the same as Embodiment 1, especially in that:

[0049] In this embodiment, bulletproof ceramics select B 4 C ceramics, the thickness of the bulletproof ceramic plate (1) is 10mm, the ultra-high molecular weight polyethylene plate (3) is made by hot pressing of ultra-high molecular weight polyethylene without weft cloth, and the thickness of the ultra-high molecular weight polyethylene plate (3) is 10mm, The shape memory alloy layer is made of 1:1 nickel-titanium alloy, and the thickness of the shape memory alloy layer is 1mm. In each embodiment of the present invention, the surface size of the lightweight functionally graded composite bulletproof armor plate is 300×300mm 2 .

[0050] In this embodiment, a method for manufacturing a lightweight functionally graded composite bulletproof armor plate of this embodiment includes the following steps:

[0051] a. Preparation of shape memory alloy layer:

[0052] Prepare a 1mm thick nickel-titani...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com