A superelastic decorative cable

A superelastic and elastic body technology, applied to bridge parts, bridges, buildings, etc., can solve problems such as broken cables, small cables, and affecting structural safety, and achieve the effect of straight cables, reasonable structures, and vibration prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

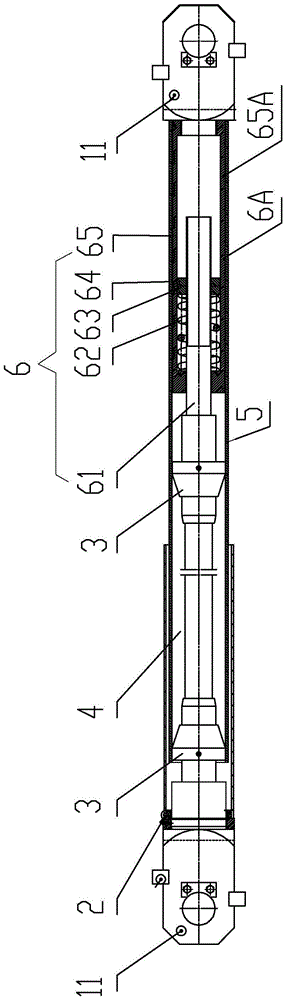

[0059] A superelastic decorative cable with fork lug structure at both ends:

[0060] Such as figure 1 As shown, the basic structure of the superelastic decorative cable with the lug structure at both ends includes an anchor cable body 4, two anchor assemblies positioned at both ends of the anchor cable body 4 and a sleeve outside the anchor cable body 4, Support ring 3 and a superelastic adjustment device 6 in the casing;

[0061] The two anchor components located at both ends of the anchor cable body 4 are anchor components I11 composed of fork ear components;

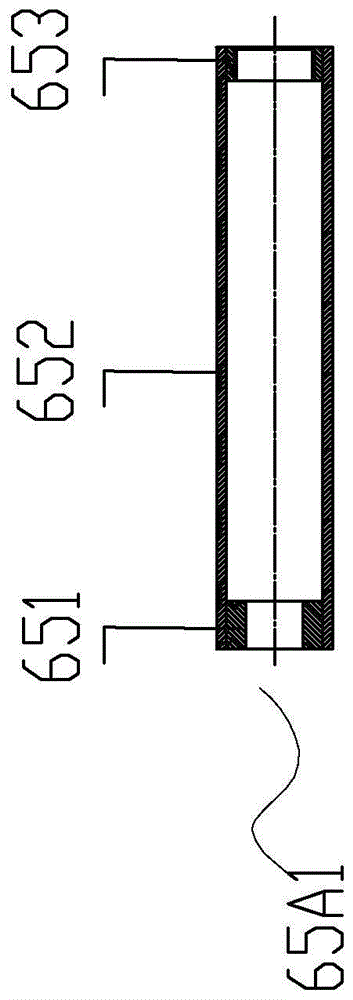

[0062] The sleeve that is positioned outside the anchor cable body 4 includes an upper sleeve 2 and a lower sleeve 5, one end of the upper sleeve 2 is connected with the fork assembly at one end of the anchor cable body 4, and the superelastic adjustment device 6 is located at In the lower casing, the super-elastic adjustment device is a super-elastic adjustment device A (6A) composed of an adjustment rod 61, a sup...

Embodiment 2

[0065] A superelastic decorative cable with a fork ear structure at one end:

[0066] Such as Figure 4 As shown, the basic structure of the superelastic decorative cable with a fork lug structure at one end is the same as that of Embodiment 1, and also includes an anchor cable body 4, two anchor assemblies located at both ends of the anchor cable body 4, and anchor cables located at the anchor cable body 4. The outer casing, the support ring 3 inside the casing and a superelastic adjustment device, the casing outside the anchor cable body 4 includes an upper casing 2 and a lower casing 5;

[0067] The difference from Example 1 is:

[0068] Only one end of the anchor assembly in this embodiment is an anchor assembly I11 composed of a fork lug assembly, and one end of the upper casing 2 is connected to the fork lug assembly at one end of the anchor cable body 4; the anchor assembly at the other end of the anchor cable body 4 It is an anchor assembly II12 composed of a pre-emb...

Embodiment 3

[0072] A superelastic decorative cable without fork ear structure:

[0073] Such as Figure 8 As shown, the basic structure of the superelastic decorative cable without fork lug structure includes an anchor cable body 4, two anchor assemblies located at both ends of the anchor cable body 4, and a sleeve outside the anchor cable body 4, and a sleeve located at the sleeve. The support ring 3 in the tube and a superelastic adjustment device 6B;

[0074] The anchor component located at one end of the anchor cable body 4 is an anchor component V15 composed of a pre-embedded pipe I71, an anchor plate 8 and a nut 9, and the superelastic decorative cable is not directly inserted into one end of the upper casing and the lower casing. In the pre-embedded pipe I71, the anchor assembly located at the other end of the anchor cable body 4 is an anchor assembly IV14 composed of the pre-embedded pipe II72, the anchor plate 8 and the super-elastic adjustment device B (6B). The super-elastic a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com