A Direct-Push Mechanical 3D Iris Device Based on Superelastic Shape Memory Alloy Blades

A technology of memory alloy and memory alloy wire, which is applied in the direction of camera, aperture, optics, etc., and can solve the problem of small opening diameter of the head

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

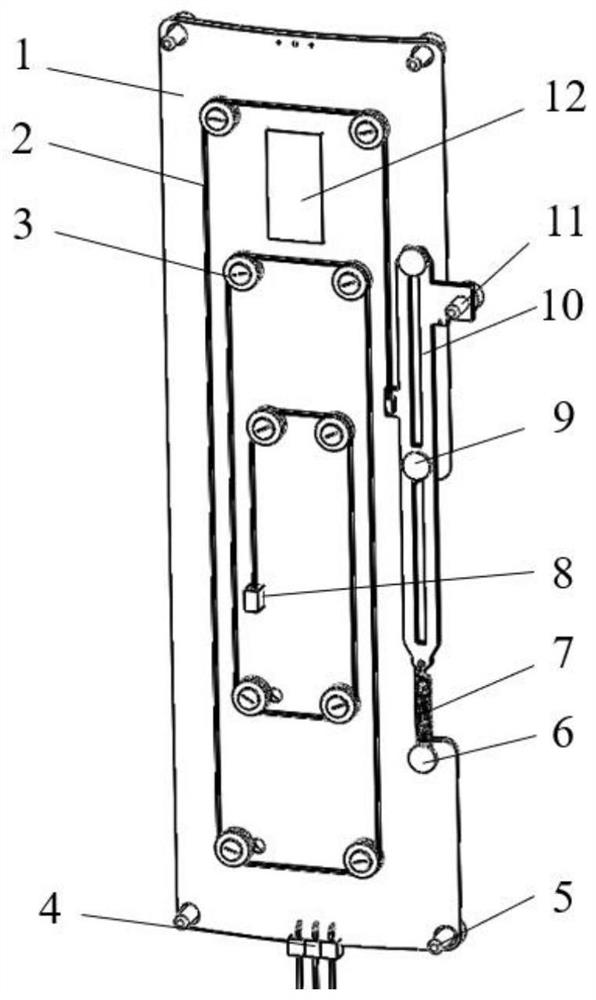

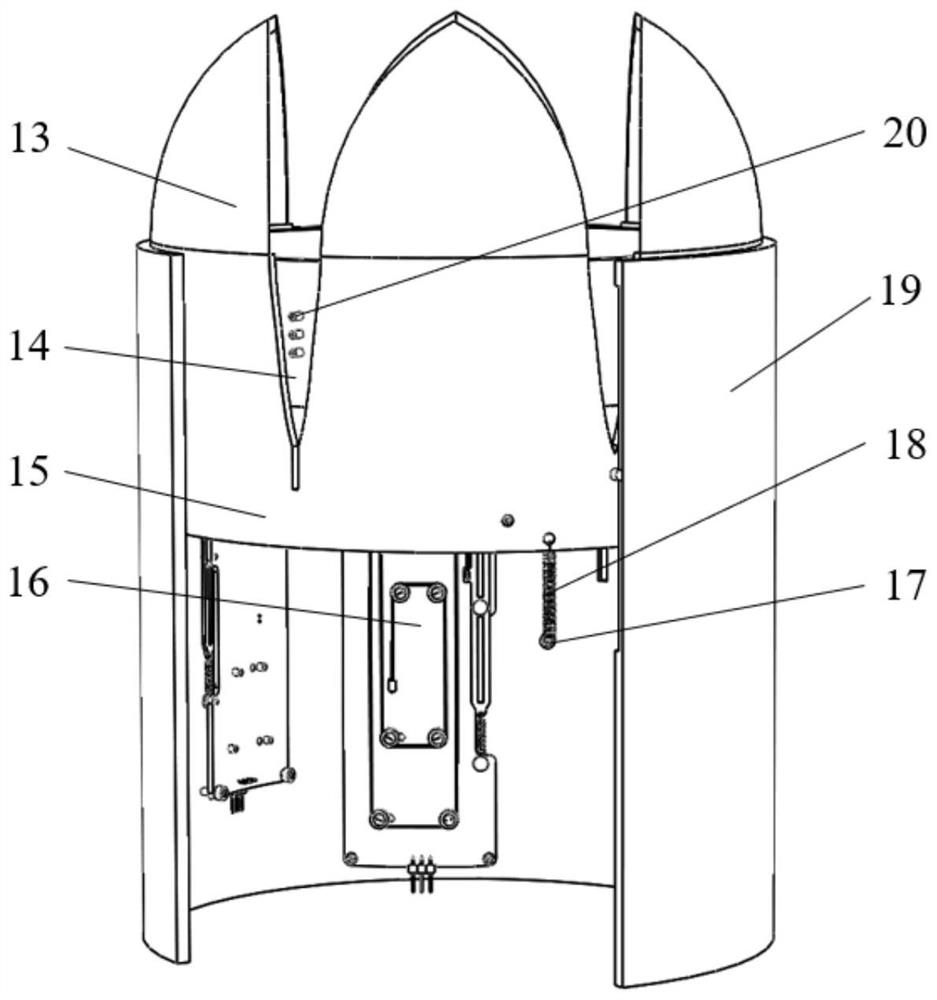

[0035] The purpose of the present invention is to provide a direct-push mechanical 3D iris device based on superelastic shape memory alloy blades. The iris blades are made of superelastic shape memory alloys. The shape of the blades can be changed. When the blades are closed, the blades are attached to the iris shell. After the blade is pushed out, due to the superelasticity of the blade, it returns to the preset curved shape, which overcomes the shortcomings of the traditional 3D spherical iris shell head that needs to be designed as a spherical surface, so that the iris device can be designed as a straight cylinder, and the head diameter increases. .

[0036] The mechanical iris device includes the following features:

[0037] Feature 1: The direct-push mechanical 3D iris device includes a superelastic shape memory alloy blade, an iris outer shell, and an iris inner shell.

[0038] Feature 2: The free shape of the superelastic shape memory alloy blade is a predetermined cur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com