Lung arterial support with valve

A pulmonary artery and valve technology, applied in the field of valved pulmonary artery stents, can solve the problems of compression deformation of the proximal end, difficulty in operation, and unsatisfactory operation, so as to increase flexibility and compliance, facilitate catheter placement, and reduce damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

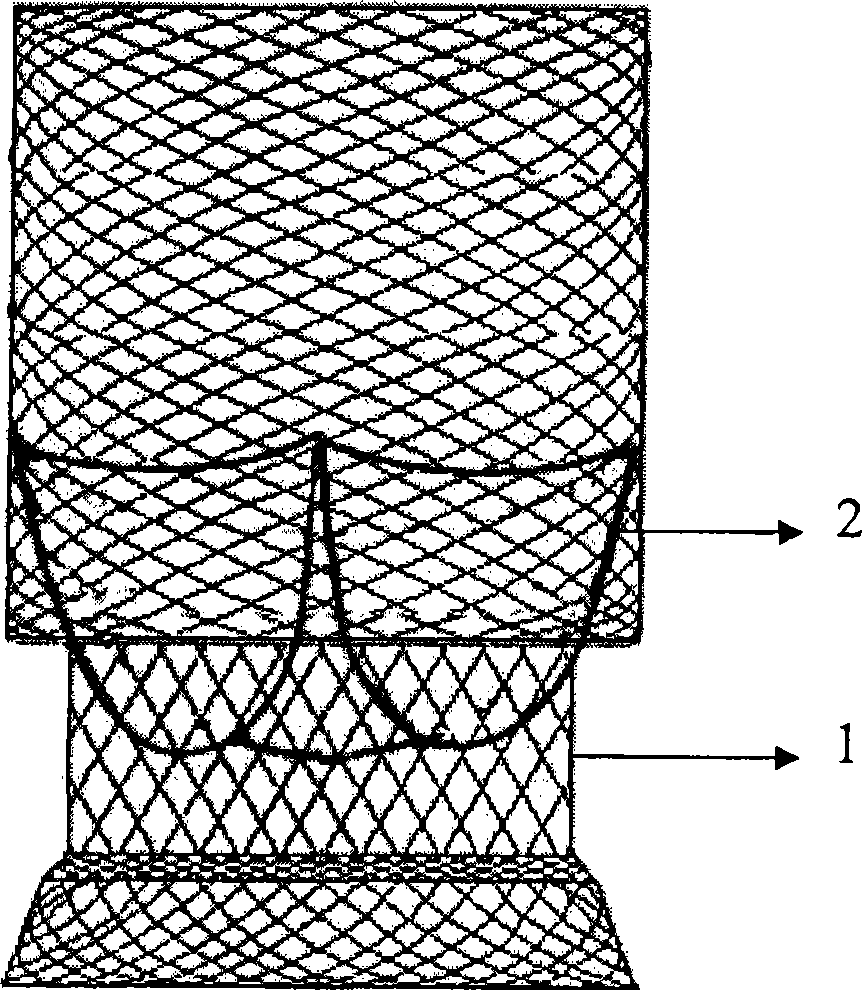

[0016] Example 1 A kind of pulmonary artery stent with valve

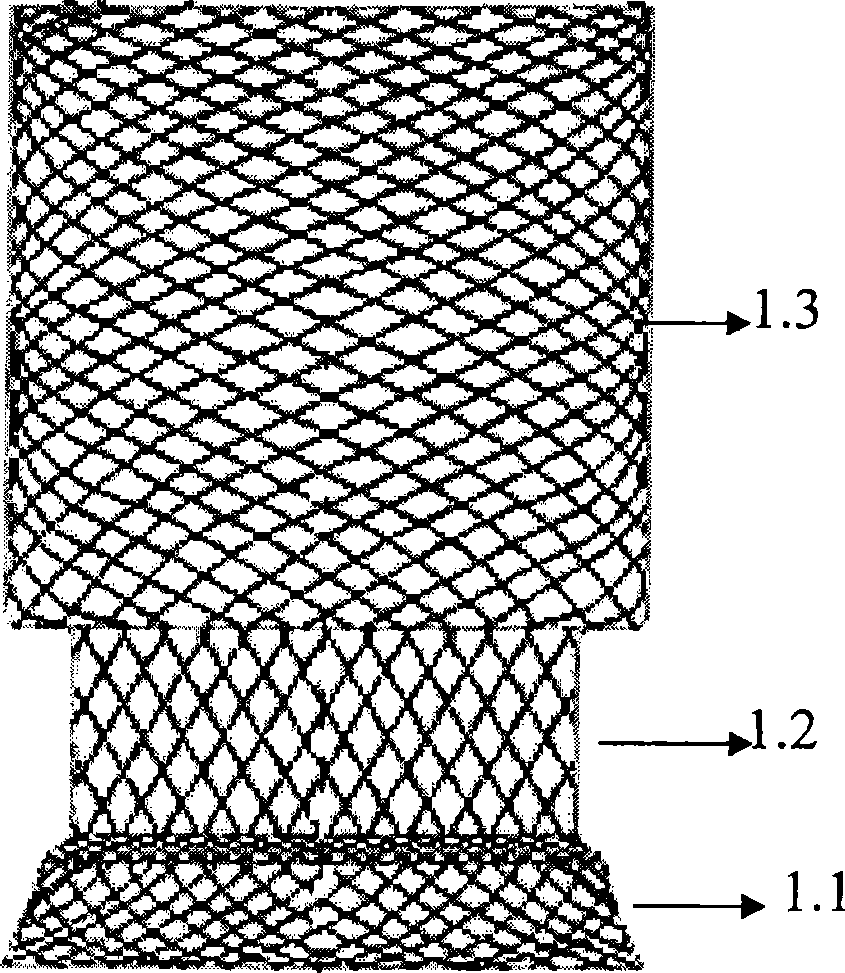

[0017] The tubular stent 1 is made of nickel-titanium shape memory alloy wire. The diameter of the alloy wire is 0.18mm. The wire is braided with a mesh mold first. After the braiding is completed, it is pressed by the stent mold, heat treated, and finally shaped. The head is 1.1 long and 3mm long, and the outer diameter of the bell mouth 22mm, the neck 1.2 is 8mm long, the outer diameter is 18mm, the body 1.3 is 12mm long, and the outer diameter is 22mm.

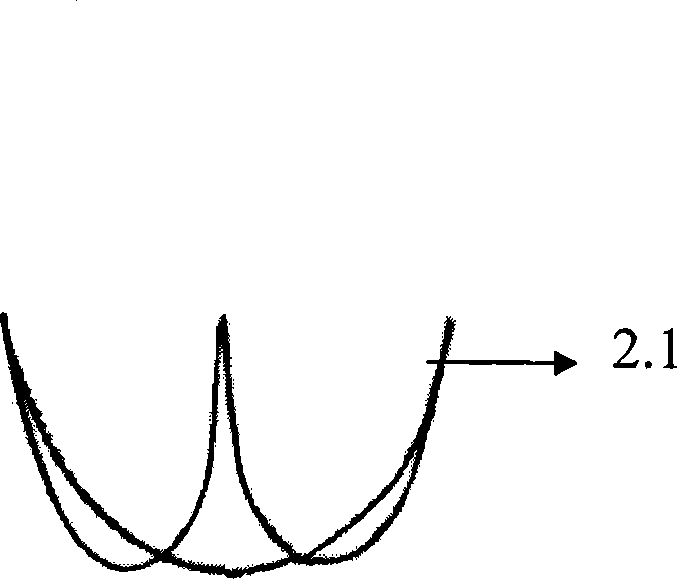

[0018] The valve stent 2.1 is made of double-stranded nickel-titanium shape memory alloy wire, the alloy wire has a diameter of 0.25mm, and is folded into three identical arc-shaped structures with an arc length of 28mm using an annulus mold. The valve leaflet 2.2 is made of fresh porcine pericardium. The surface impurities are removed as usual. The cells are treated by 0.25% trypsin digestion. After being soaked in 0.6% glutaraldehyde for 36 hours, the PBS solution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com