A kind of preparation method of porous nickel-titanium/hydroxyapatite composite material

A technology of hydroxyapatite and composite materials, which is applied in the field of preparation of porous nickel-titanium/hydroxyapatite composite materials, which can solve the problems of uneven penetration of HA coating, interface corrosion, coating peeling, etc., and achieve stress relief - Shielding effect, increasing bonding strength, facilitating adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

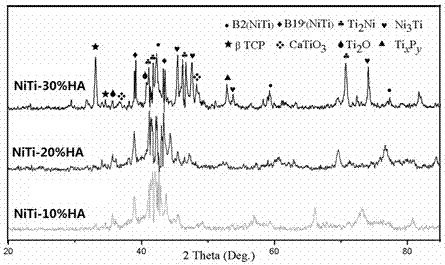

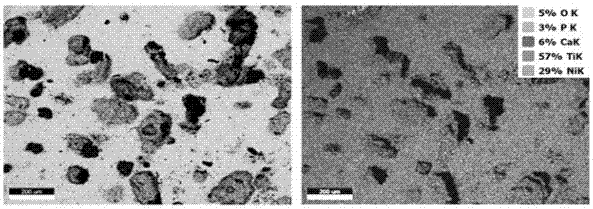

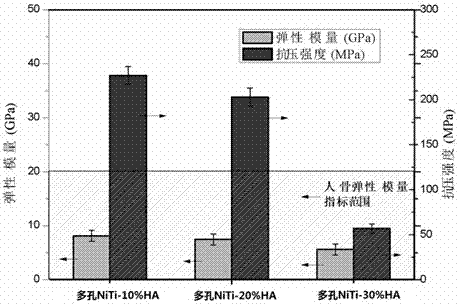

Embodiment 1

[0029] The preparation method of the porous nickel-titanium / hydroxyapatite composite material described in this embodiment specifically includes the following steps:

[0030] (1) Weighing: According to the mass percentage of 58.8% Ni and 41.20% Ti, respectively weigh the Ti metal powder with a purity of 99.9% and a particle size of 45 μm and the Ni metal powder with a purity of 99.5% and a particle size of 75 μm;

[0031] (2) Preparation of alloy raw material powder: put the metal powder weighed in step (1) into the ball mill tank of a ball mill, vacuumize to 6 Pa, and then ball mill and mix the powder for 10 hours to obtain mixed Ni-Ti metal powder;

[0032] (3) Weighing: According to the mass percentage of mixed Ni-Ti metal powder 90% and HA10% obtained in step (2), respectively weigh mixed Ni-Ti metal powder and HA with a purity of 99.5% and an average particle size of 100 nm powder;

[0033] (4) Preparation of composite raw material powder: put the powder weighed in step ...

Embodiment 2

[0042] The preparation method of the porous nickel-titanium / hydroxyapatite composite material described in this embodiment specifically includes the following steps:

[0043] (1) Weighing: According to the mass percentage of 56% Ni and 44% Ti, respectively weigh the Ti metal powder with a purity of 99.9% and a particle size of 40 μm and the Ni metal powder with a purity of 99.5% and a particle size of 65 μm;

[0044] (2) Preparation of alloy raw material powder: put the metal powder weighed in step (1) into the ball mill tank of a ball mill, vacuumize to 7 Pa, and then ball mill and mix the powder for 12 hours to obtain mixed Ni-Ti metal powder;

[0045] (3) Weighing: According to the mass percentage of mixed Ni-Ti metal powder 90% and HA10% obtained in step (2), weigh the mixed Ni-Ti metal powder and HA with a purity of 99.5% and an average particle size of 120 nm powder;

[0046] (4) Preparation of composite raw material powder: put the powder weighed in step (3) into the b...

Embodiment 3

[0053] The preparation method of the porous nickel-titanium / hydroxyapatite composite material described in this embodiment specifically includes the following steps:

[0054] (1) Weighing: According to the mass percentage of Ni57% and Ti43%, respectively weigh the Ti metal powder with a purity of 99.9% and a particle size of 30 μm and the Ni metal powder with a purity of 99.5% and a particle size of 55 μm;

[0055] (2) Preparation of alloy raw material powder: put the metal powder weighed in step (1) into the ball mill tank of a ball mill, vacuumize to 8Pa, and then ball mill and mix the powder for 16 hours to obtain mixed Ni-Ti metal powder;

[0056] (3) Weighing: According to the mass percentage of mixed Ni-Ti metal powder 80% and HA20% obtained in step (2), weigh the mixed Ni-Ti metal powder and HA with a purity of 99.5% and an average particle size of 130 nm powder;

[0057] (4) Preparation of composite raw material powder: put the powder weighed in step (3) into the ball...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com